Method for one-step synthesis of fluorescent carbon nano-particle solution

A technology of carbon nanoparticles and fluorescence, applied in nanotechnology, chemical instruments and methods, luminescent materials, etc., can solve the problems of low fluorescence performance of carbon nanoparticles, inability to use biological markers, environmental pollution, etc., to achieve low cost, Satisfy industrial application, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolution of materials: Weigh 0.5 grams of citric acid and 0.1 grams of ammonium oxalate and mix them, grind them finely in a mortar, pour the finely ground mixture into a beaker, add 20 ml of ethylene glycol, put it into a magnet, and place it under a magnetic force Stir on a blender until the solid is completely dissolved to obtain a colorless transparent solution.

[0020] (2) Generation of fluorescent carbon nanoparticles: Pour the above solution into a reaction kettle lined with Teflon, tighten the lid of the reaction kettle, place it in a constant temperature drying oven at 170°C for 3 hours, and then take it out of the constant temperature drying oven The reaction kettle is naturally cooled to room temperature, the solution in the kettle is brownish yellow, and the obtained liquid is a fluorescent carbon nanoparticle solution.

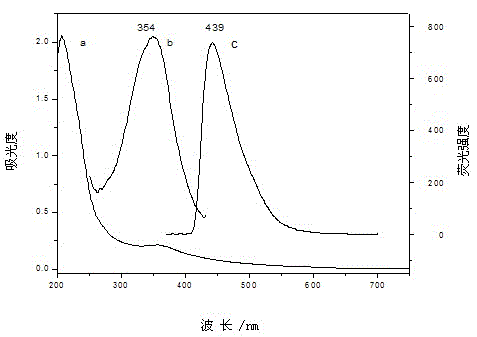

[0021] The carbon nanoparticle solution in this example was diluted and characterized by fluorescence and ultraviolet spectroscopy...

Embodiment 2

[0023] (1) Dissolution of materials: Weigh 0.5 g of glucose and 0.05 g of ammonium oxalate and mix them, grind them in a mortar, pour the grinded mixture into a beaker, add 20 ml of ethylene glycol, put in a magnet, and place in a magnetic stirrer Stir until the solid is completely dissolved, and the resulting liquid is a fluorescent carbon nanoparticle solution.

[0024] (2) Generation of fluorescent carbon nanoparticles: Pour the above solution into a reaction kettle lined with Teflon, tighten the lid of the reaction kettle, place it in a constant temperature drying oven and heat at 140°C for 3 hours, and then take it out of the constant temperature drying oven The reaction kettle is naturally cooled to room temperature, the solution in the kettle is brownish yellow, and the obtained liquid is a fluorescent carbon nanoparticle solution.

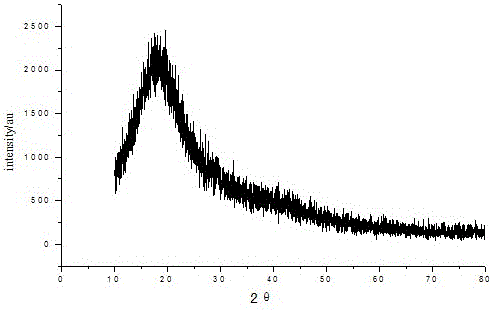

[0025] The carbon nanoparticles in this example were characterized by XRD, as shown in Figure 4: a broad peak appears at 2θ=20°, which is ...

Embodiment 3

[0027] (1) Dissolution of materials: Weigh 0.5 g of tartaric acid and 0.2 g of ammonium oxalate and mix them, grind them finely in a mortar, pour the finely ground mixture into a beaker, add 20 ml of ethylene glycol, put in a magnet, and place in a magnetic stirrer Stir until the solid is completely dissolved, and the resulting liquid is a fluorescent carbon nanoparticle solution.

[0028] (2) Generation of fluorescent carbon nanoparticles: Pour the above solution into a reaction kettle lined with Teflon, tighten the lid of the reaction kettle, place it in a constant temperature drying oven at 180°C for 3 hours, and then take it out of the constant temperature drying oven The reaction kettle is naturally cooled to room temperature, the solution in the kettle is brownish yellow, and the obtained liquid is a fluorescent carbon nanoparticle solution.

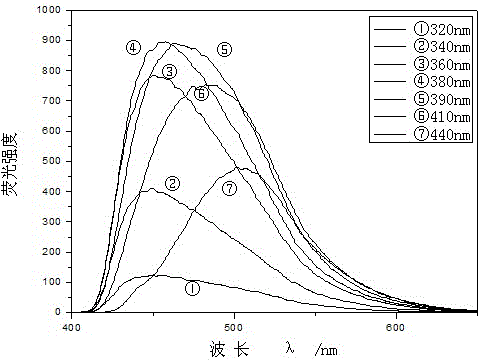

[0029] Fluorescent characterization was performed on the diluted carbon nanoparticle solution in this example. See image 3 , i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com