A kind of preparation method of carbon dot solid phosphor powder

A fluorescent powder and solid-state technology, which is applied in the field of carbon dot solid-state phosphor preparation, can solve the problems such as the disappearance of fluorescence characteristics, and achieve the effects of easy preservation, simple preparation method, and stable photochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 1.0 g of citric acid and 0.10 g of ammonium oxalate, mix and grind them evenly, and place them in a constant temperature drying oven at 190° C. for 1 hour to react. After taking out and cooling naturally, a brown foamy solid was obtained. Weigh 0.0001 g of the solid powder and ultrasonically disperse it in water to obtain a fluorescent carbon dot solution. Then, 100 grams of starch was added to the fluorescent carbon dot solution, and ultrasonic dispersion was continued for 30 minutes. Vacuum drying the mixed solution of fluorescent carbon dots and starch to obtain carbon dot solid fluorescent powder.

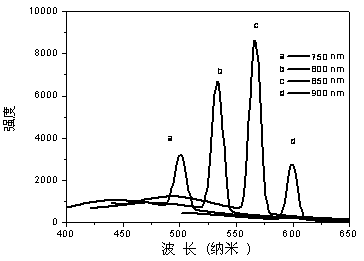

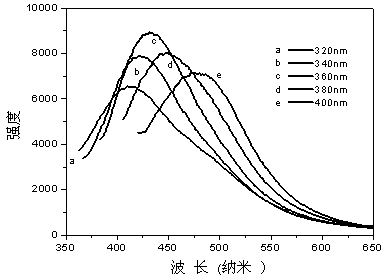

[0020] figure 1 It is the down-conversion fluorescence spectrum diagram corresponding to the carbon dot solid-state phosphor in Example 1. The fluorescence results show that the sample has good fluorescence performance in the excitation wavelength range of 350-600 nanometers. As the excitation wavelength increases, the maximum peak wavelength of the emitted ligh...

Embodiment 2

[0023] Weigh 1.0 g of ascorbic acid and 0.10 g of urea, mix and grind them evenly, place them in a constant temperature drying oven at 120° C. and heat for 5 hours. After taking out and cooling naturally, a brown foamy solid was obtained. Weigh 0.01 g of the solid powder and ultrasonically disperse it in water to obtain a fluorescent carbon dot solution. Then, 100 grams of starch was added to the fluorescent carbon dot solution, and ultrasonic dispersion was continued for 30 minutes. Vacuum drying the mixed solution of fluorescent carbon dots and starch to obtain carbon dot solid fluorescent powder.

Embodiment 3

[0025] 1.0 g of malic acid and 0.10 g of glycine were weighed, mixed and ground evenly, and placed in a constant temperature drying oven at 210° C. for 1 hour to react. After taking out and cooling naturally, a brown foamy solid was obtained. Weigh 0.1 g of the solid powder and ultrasonically disperse it in water to obtain a solution of fluorescent carbon dots. Then, 100 grams of starch was added to the fluorescent carbon dot solution, and ultrasonic dispersion was continued for 30 minutes. The mixed solution of fluorescent carbon dots and starch is vacuum-dried to obtain solid-state fluorescent powder of carbon dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com