Solid-state yellow light carbon quantum dot composite based on multiple emission peaks and preparation method thereof

A technology of carbon quantum dots and composites, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as missing spectra and complicated preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 10 mL of formamide, mix it with 10 mL of glycerol evenly, then add 1.6 g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0034] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with tetrafluoroethylene, and solvothermally reacted in an oven at 180 ° C for 4 h.

[0035] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. The obtained solid was dried in a drying oven at 60° C. to obtain a fibrous yellow solid, which was ground into a powder with a mortar to prepare a solid yellow carbon quantum dot composite powder.

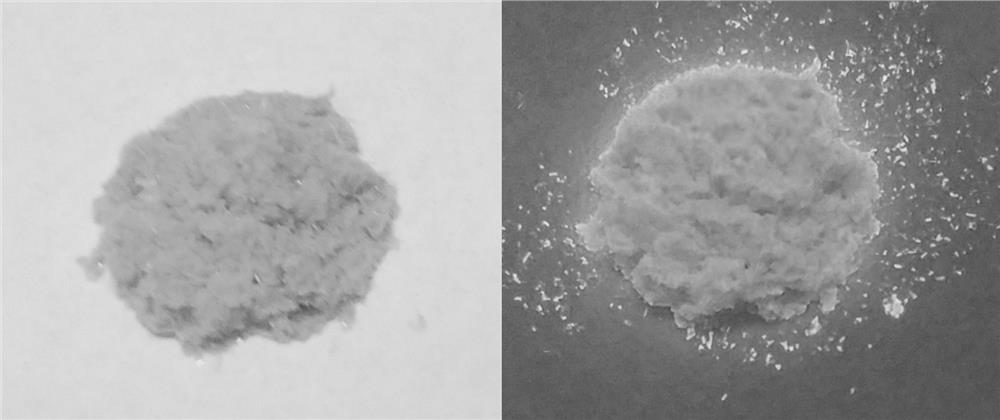

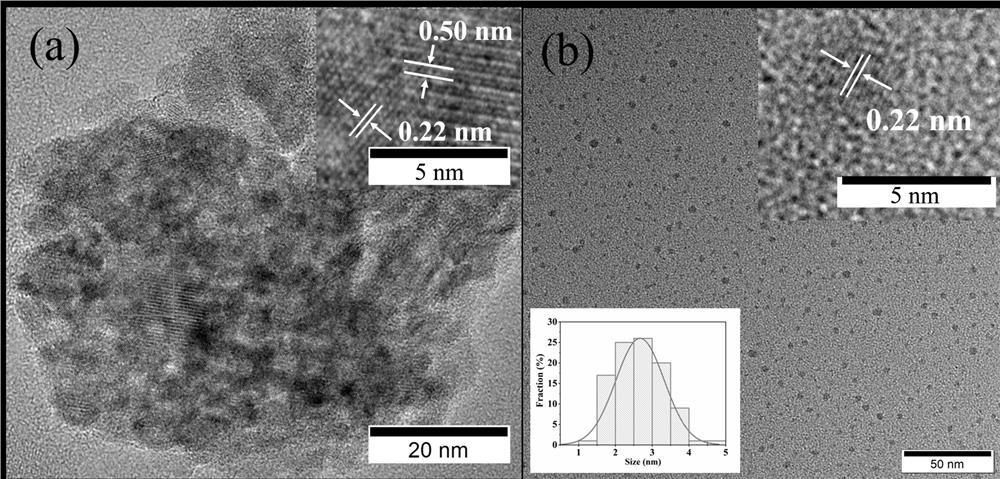

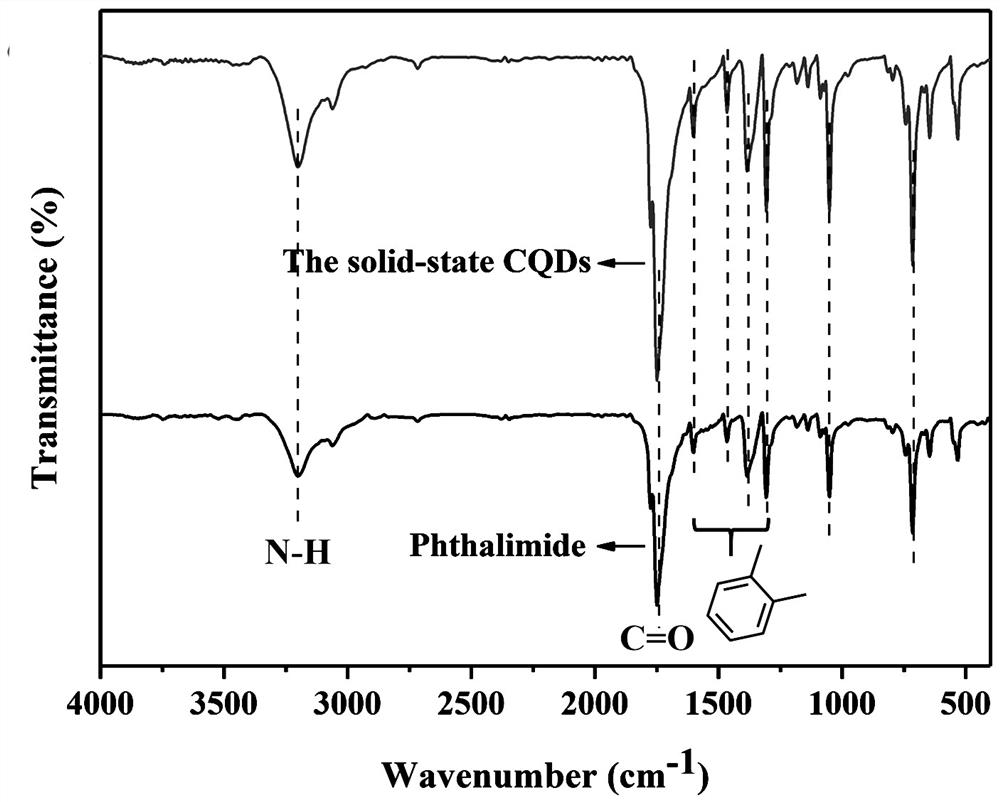

[0036] figure 1 It is the physical picture of the solid yellow light carbon quantum dot composite prepared above under the irradiation of fluorescent lamp and 365nm ultraviolet lamp. The left picture shows that the carbon quantum dot composite i...

Embodiment 2

[0047] Take 10 mL of formamide, mix it with 10 mL of glycerol evenly, add 2.4 g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0048] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with tetrafluoroethylene, and solvothermally reacted in an oven at 180 ° C for 6 h.

[0049] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. The obtained solid was dried in a drying oven at 60° C. to obtain a fibrous yellow solid, which was ground into a powder with a mortar to prepare a solid yellow carbon quantum dot composite powder.

[0050] from Figure 9 It can be seen that the fluorescence emission spectrum of the solid-state yellow light carbon quantum dot composite has multi-peak characteristics, with emission peaks at 525, 565 and 615 nm, respectively, and the fluorescence sp...

Embodiment 3

[0052] Take 15mL of formamide, mix with 5mL of glycerol evenly, add 1.6g of phthalic acid, stir, mix and disperse evenly at room temperature to obtain a reaction solution.

[0053] The above reaction solution was placed in a 40 mL stainless steel autoclave lined with tetrafluoroethylene, and solvothermally reacted in an oven at 160 ° C for 4 h.

[0054] After the reaction was completed and cooled to room temperature, the obtained solid-liquid mixed product was taken out and vacuum-filtered with a 0.22 μm microporous membrane. The obtained solid was dried in a drying oven at 60° C. to obtain a fibrous yellow solid, which was ground into a powder with a mortar to prepare a solid yellow carbon quantum dot composite powder.

[0055] from Figure 10 It can be seen that the fluorescence emission spectrum of the solid-state yellow light carbon quantum dot composite has multi-peak characteristics, with emission peaks at 525, 565 and 615 nm, respectively, and the fluorescence spectrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com