A kind of method for preparing high-purity tetraethylammonium hydroxide by continuous electrolysis

A tetraethylammonium hydroxide, high-purity technology, applied in the electrolysis process, electrolysis components, electrolysis organic production and other directions, can solve the problems of difficult large-scale safe production, low product yield, low product purity, etc. Current efficiency and product conversion, reduced energy consumption, improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

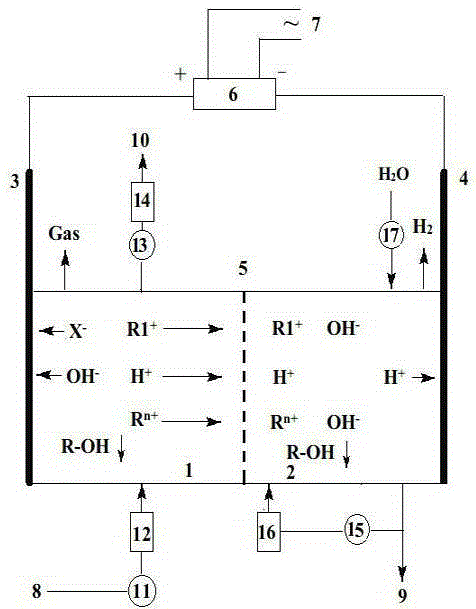

[0027] Aqueous tetraethylammonium bicarbonate solution with a concentration of 40% is put into the anode chamber 1 from the feed inlet 8 of the raw material. An aqueous tetraethylammonium hydroxide solution with a concentration of 2% was added to the cathode chamber 2 from the supplementary water inlet. Turn on the circulating pumps 11, 13, 15, 17. Connect the alternating current 7, connect the current between the anode plate 3 in the anode chamber 1 and the cathode plate 4 in the cathode chamber 2, so that the current density is 1000A / m 2 , the reaction temperature is 25°C. In the anode compartment 1, tetraethylammonium carbonate is hydrolyzed to generate cations (CH 3 CH 2 ) 4 N + and anion CO 3 2- , water will be hydrolyzed to generate H + and OH - . Cation (CH 3 CH 2 ) 4 N + 、H + with the metal cation R in solution n+ Through the cation exchange membrane 5 into the cathode chamber 2. while the anion CO 3 2- with OH - Arriving at the anode plate 3, the e...

Embodiment 2

[0029] Change the concentration of tetraethylammonium bicarbonate to tetraethylammonium chloride with a concentration of 30%, change the concentration of tetraethylammonium hydroxide initially added to the cathode chamber 2 to 3%, and change the current density to 1500A / m 2 , the reaction temperature was changed to 35°C, and the rest of the steps were the same as in Example 1. After the electrolytic reaction, when the concentration of tetraethylammonium hydroxide in the cathode chamber 2 was greater than 25%, the product was output from the outlet 9 at the bottom of the cathode chamber 2. The concentration of each metal ion in the product is less than 20ppb, and the carbonate radical is less than 100ppm, as shown in Table 1; the product conversion rate of this method is 98.3%.

Embodiment 3

[0031] Change the concentration of tetraethylammonium bicarbonate to tetraethylammonium bromide with a concentration of 50%, change the concentration of tetraethylammonium hydroxide initially added to the cathode chamber 2 to 4%, and change the current density to 1700A / m 2 , the reaction temperature was changed to 45°C, and the rest of the steps were the same as in Example 1. After the electrolytic reaction, when the concentration of tetraethylammonium hydroxide in the cathode chamber 2 was greater than 25%, the product was output from the outlet 9 at the bottom of the cathode chamber 2. The concentration of each metal ion in the product is less than 20ppb, and the carbonate radical is less than 100ppm, as shown in Table 1; the product conversion rate of this method is 98.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com