A method of producing gypsum whiskers with hexagonal cross-section and low phosphorous content

A gypsum whisker, hexagonal technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve problems such as corrosion, limited source of raw materials, limited application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

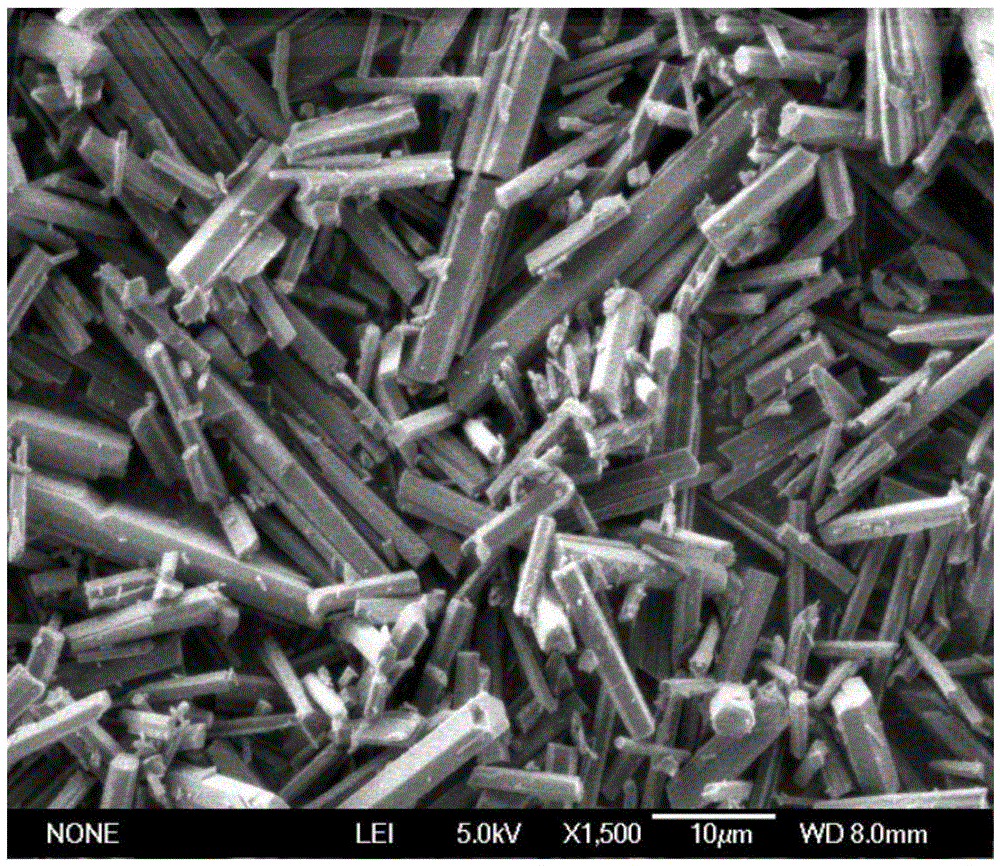

Embodiment 1

[0027]A method of making whiskers of gypsum hemihydrate in phosphoric acid. It includes the steps of preparing calcium phosphate solution, reacting calcium phosphate with sulfuric acid, preparing hemihydrate gypsum whiskers and the like. The preparation step of calcium phosphate solution is to use 480ml concentration to be 30% (P 2 o 5 ) of industrial phosphoric acid with 40 grams of phosphate rock (P 2 o 5 32%) for leaching chemical reaction, the temperature is controlled at 85°C, after 2 hours of reaction, the liquid phase is separated and filtered, and the filter residue is left for the next round to react with industrial phosphoric acid. The filtrate contains Ca 2+ =0.63mol / L calcium phosphate solution. Under stirring conditions, to 200ml Ca 2+ =0.63mol / L calcium phosphate solution, add 1.0ml of 1.0‰ polyacrylamide, after mixing, gradually add 40 grams of 30% sulfuric acid solution, stir and react at 93°C for 120 minutes to form gypsum whiskers suspended in phosphor...

Embodiment 2

[0029] A method of making low phosphorus content hemihydrate gypsum whiskers in phosphoric acid. It includes the steps of preparing calcium phosphate solution, reacting calcium phosphate with sulfuric acid, preparing hemihydrate gypsum whiskers and the like. The preparation step of calcium phosphate solution is with embodiment 1. Take 200mlCa 2+ =0.63mol / L calcium phosphate solution, add 1.0‰ polyacrylamide 1.0ml under stirring condition, gradually add 40 grams of sulfuric acid solution with a concentration of 30% after mixing, stir and react at 103°C for 30 minutes, Gypsum whiskers are formed suspended in phosphoric acid. The gypsum whisker suspension was filtered, washed three times with water, and dried at 110° C. to obtain 32.4 grams of gypsum whisker hemihydrate. Analysis of phosphorus pentoxide (P 2 o 5 ) content is 0.291%, and the crystal form is hexagonal rod.

Embodiment 3

[0031] A method of making low phosphorus content anhydrite whiskers in phosphoric acid. It includes the steps of preparing calcium phosphate solution, reacting calcium phosphate with sulfuric acid, preparing anhydrous gypsum whiskers and the like. The preparation step of calcium phosphate solution is to use the concentration that 480ml obtains after the gypsum whisker is produced in embodiment 2 to be 30% (P 2 o 5 ) of phosphoric acid, first react with the primary filter residue filtered out in Example 1 at 85°C for 1 hour, filter, wash the filter residue, and dry to obtain 3.81 grams of the secondary filter residue, where P 2 o 5 The content is 2.4%. Continue to react the filtered solution (semi-acid for short) with phosphate rock powder at 85°C for 2 hours, filter and separate the liquid phase to obtain Ca-containing 2+ It is 0.87mol / L calcium phosphate solution. Add 100ml of 0.87mol / L calcium phosphate solution gradually into 20g of 40% sulfuric acid solution, and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com