Multistage dual-hinge-shaft inverted oil cylinder

A double hinge shaft, inverted technology, applied in the direction of fluid pressure actuating device, can solve the problems of poor low pressure sealing performance, poor resistance to eccentric load, increased cost, etc., to ensure low pressure sealing performance and anti eccentric load. capacity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

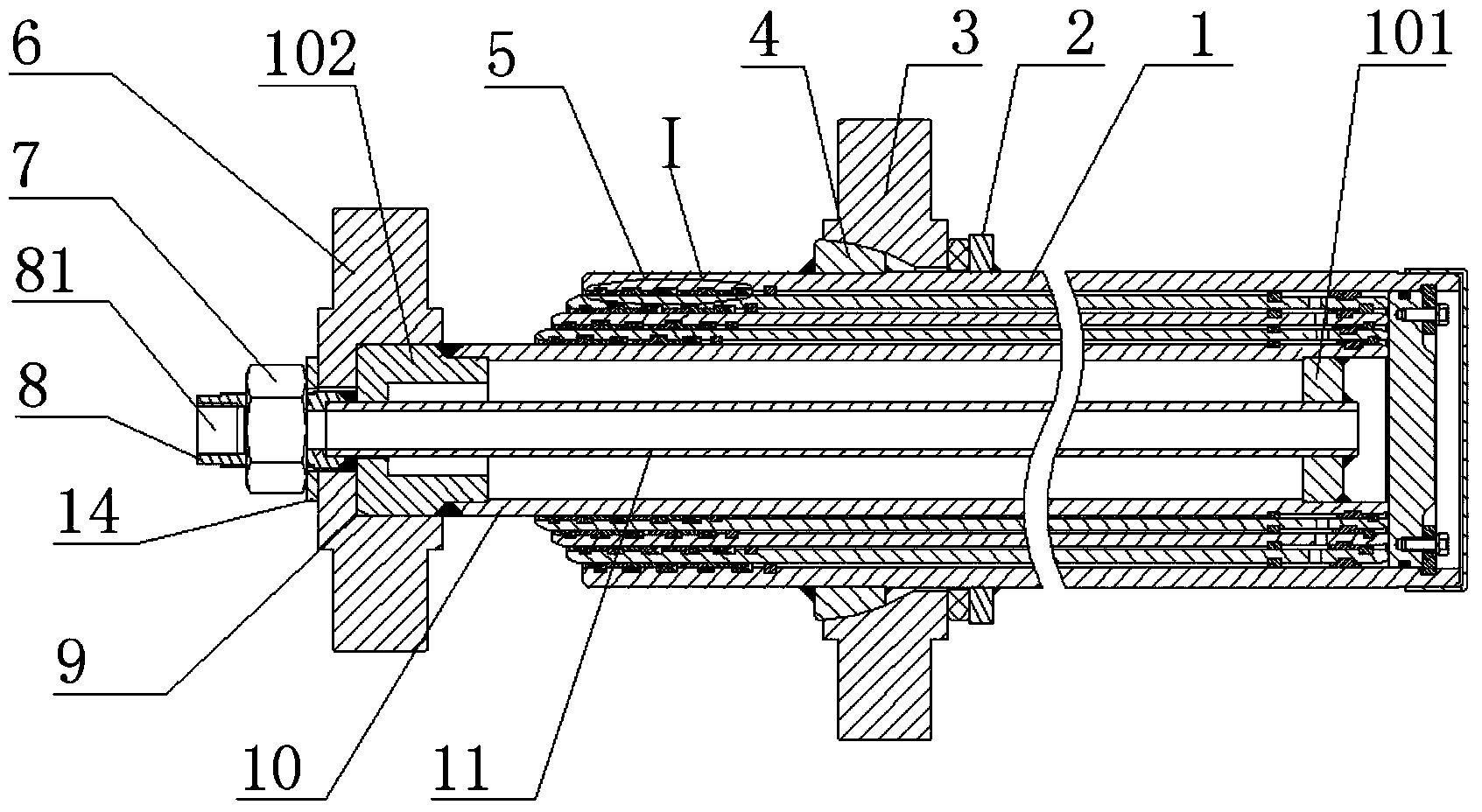

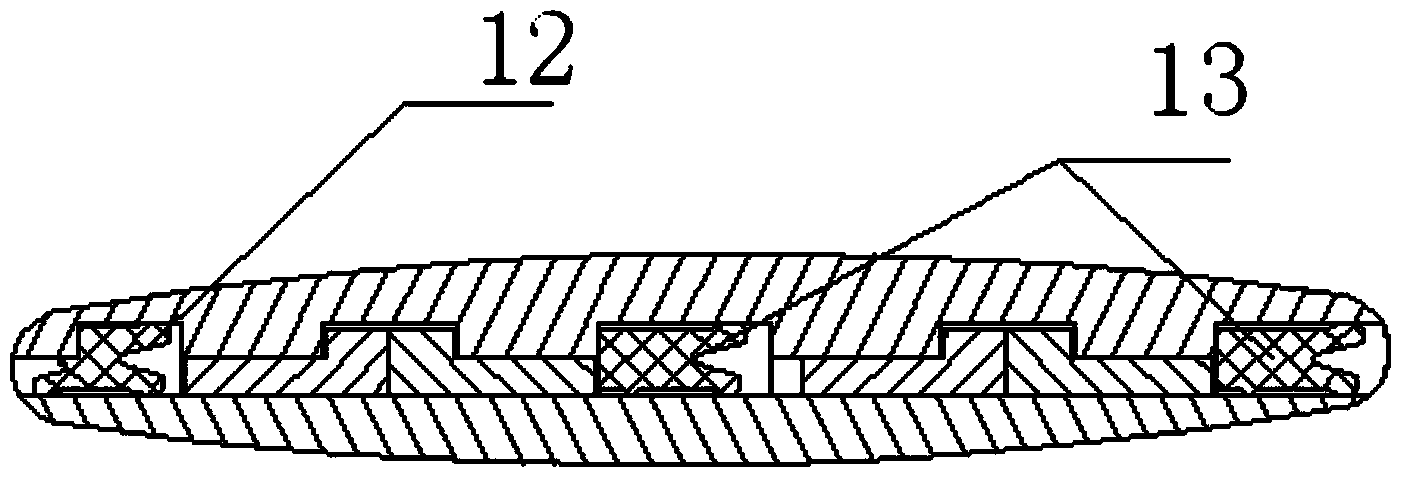

[0015] like figure 1 and figure 2 As shown, a multi-stage double-hinge shaft inverted oil cylinder includes: a base cylinder assembly, cylinder barrel assemblies at all levels, a piston rod assembly, a cylinder bottom assembly and a sealing assembly 5; the sealing assembly 5 includes a dust-proof ring 12 and two Y-shaped sealing rings 13; the base cylinder assembly includes the base cylinder 1, the compression ring 2 fixed on the base cylinder 1 and the base cylinder hinge seat 4, and also includes the base cylinder hinge seat 4 The base cylinder hinge shaft 3; the piston rod assembly includes the piston rod 10 and the piston rod hinge shaft 6 installed at the end of the piston rod 10; the base cylinder hinge shaft 3 is hinged with the carriage, and the piston rod hinge shaft 6 is hinged with the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com