Spring bracket allowing on-spot adjustment

A spring bracket and adjustable technology, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of pipeline safety operation, pipeline operation safety, pipeline operation safety hazards, etc., to achieve pipeline operation Safe and reliable, avoiding frictional thrust, and conducive to safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

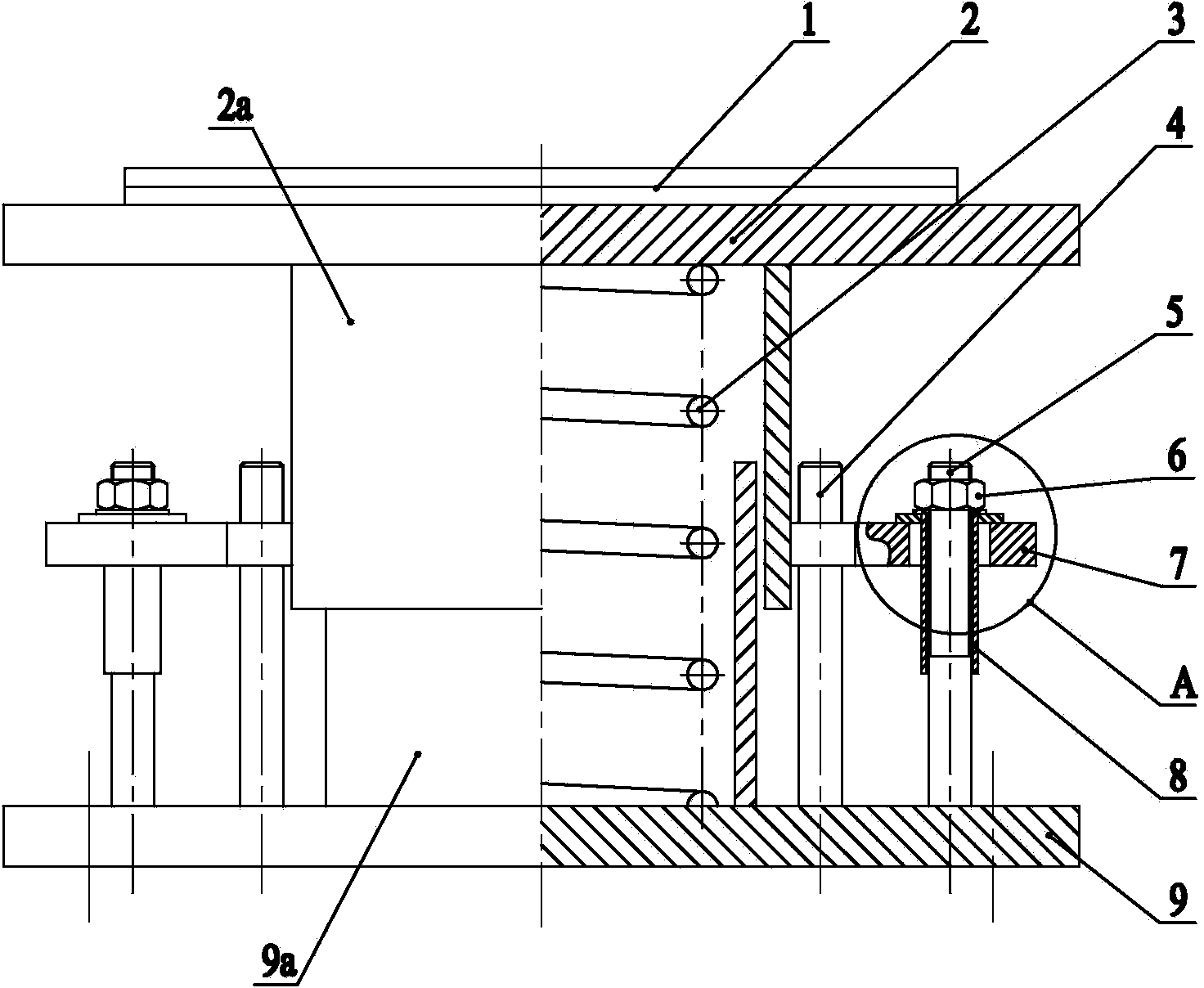

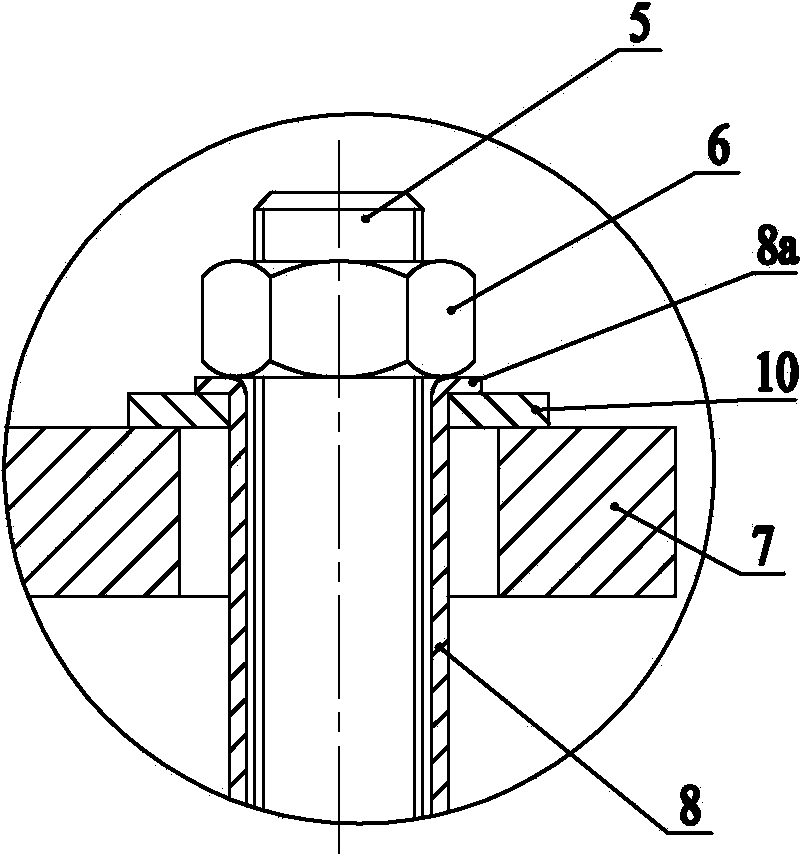

[0021] As shown in the figure: the field adjustable spring bracket in the embodiment is mainly composed of the top sliding pair 1, the upper bracket 2 of the spring bracket, the working spring 3, the lower bracket 9 of the spring bracket and the load preload value adjustment mechanism. The top sliding pair 1 is installed on the top of the bracket 2 on the spring bracket, and the top sliding pair 1 is used to be arranged under the pipe bracket to provide support for the pipe bracket and the pipeline. The pipe bracket and the pipeline can be placed on the top sliding pair 1 Move horizontally; the bottom surface of the upper bracket 2 of the spring bracket is provided with a vertically downward lower sleeve 2a, the lower bracket 9 of the spring bracket is arranged under the upper bracket 2 of the spring bracket, and the spring A vertically upward upper sleeve 9a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com