LED street lamp light source module, manufacturing method thereof and cooling device thereof

A technology of LED street lamps and LED light sources, applied in cooling/heating devices, light sources, electric light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

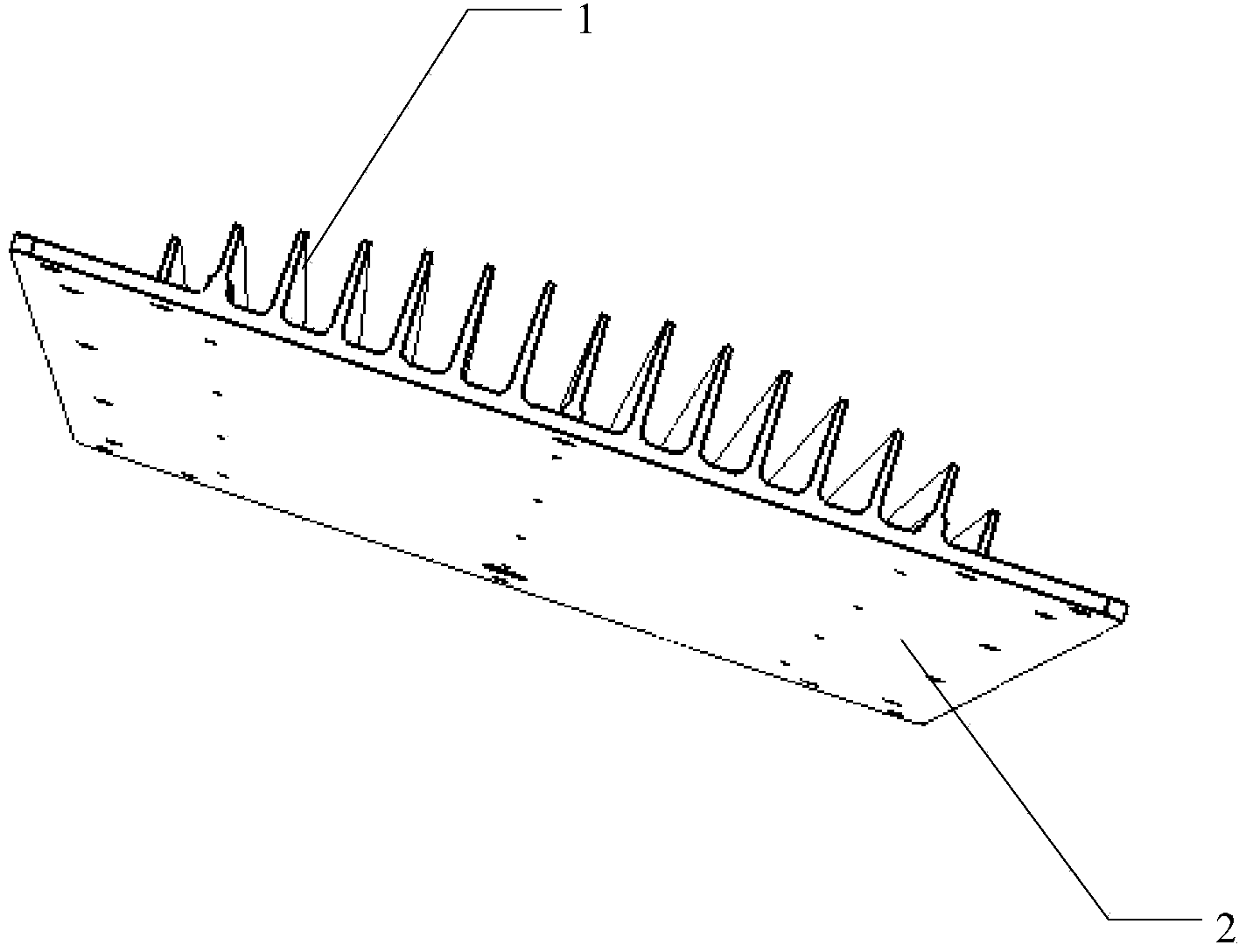

[0048] This embodiment discloses a heat dissipation device for LED street lamps, such as Figure 4 As shown, the LED street lamp cooling device includes a light source mounting plate 22, the first surface 221 of the light source mounting plate 22 is used to install the LED light source; and a plurality of detachable cooling fins arranged on the second surface 222 of the light source mounting plate 22 Each fin unit 21 includes a plurality of fins 211 .

[0049] It should be noted that, for the convenience of description, in the present invention, the first surface on which the LED light source is installed on the light source mounting board is defined as the front of the light source mounting board, and the second surface on the light source mounting board used to install the heat dissipation fin unit is also defined as That is, the surface opposite to the front of the light source mounting plate is defined as the back of the light source mounting plate. The front and back of t...

Embodiment 2

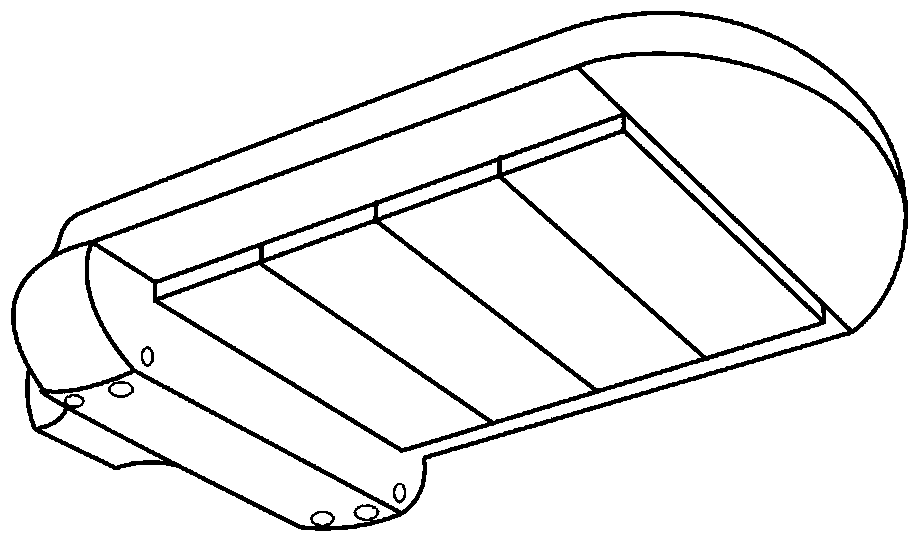

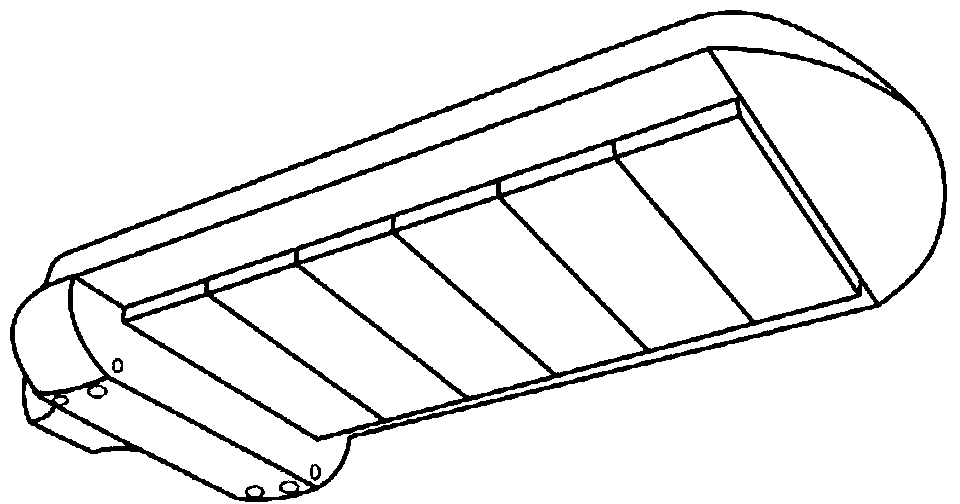

[0060] In this embodiment, a LED street light source module is provided, such as Figure 8 As shown, it includes an LED light source 33, a reflector 34, a lampshade 35, a lampshade pressure frame 36 and a heat dissipation device, wherein the heat dissipation device includes a light source mounting plate 32 and a plurality of detachable heat dissipation fins located on the back of the light source mounting plate Unit 31.

[0061] The LED light source 33, the reflector 34, the lampshade 35, and the lampshade pressure frame 36 are located on the front of the light source installation board, and are fixed on the front of the light source installation board by screws or heat-conducting silica gel. The reflector 34 is used to reflect the outgoing light that deviates from the central axis of the light source module to the vicinity of the central axis of the light source module to increase the concentrated irradiation effect of the outgoing light; the lampshade 35 and the lampshade pr...

Embodiment 3

[0067] This embodiment provides a method for manufacturing an LED street lamp light source module, including the following steps:

[0068] Step 101: Provide heat dissipation device, LED light source, reflector, lampshade and lampshade pressure frame.

[0069] The heat dissipation device is a heat dissipation device comprising a separate light source mounting plate and heat dissipation fins.

[0070] Step 102: According to the power of the LED light source, select the number of heat dissipation fin units matching the power of the LED light source, and install the heat dissipation fin units on the back of the light source mounting board.

[0071] Step 103: fixing the LED light source on the front of the light source mounting plate;

[0072] Step 104: Fix the reflector and the lampshade on the front of the light source mounting plate with the lampshade pressing frame.

[0073] The manufacturing method of the LED street light source module provided in this embodiment uses separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com