Carbon dioxide compressor performance test system with transcritical/subcritical testing function

A carbon dioxide, test function technology, applied in pump testing, machine/engine, mechanical equipment, etc., can solve problems such as explosion, accumulator pressure increase, safety valve jumping, etc., to achieve simple and convenient operation, reduce pressure requirements, Reduce the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

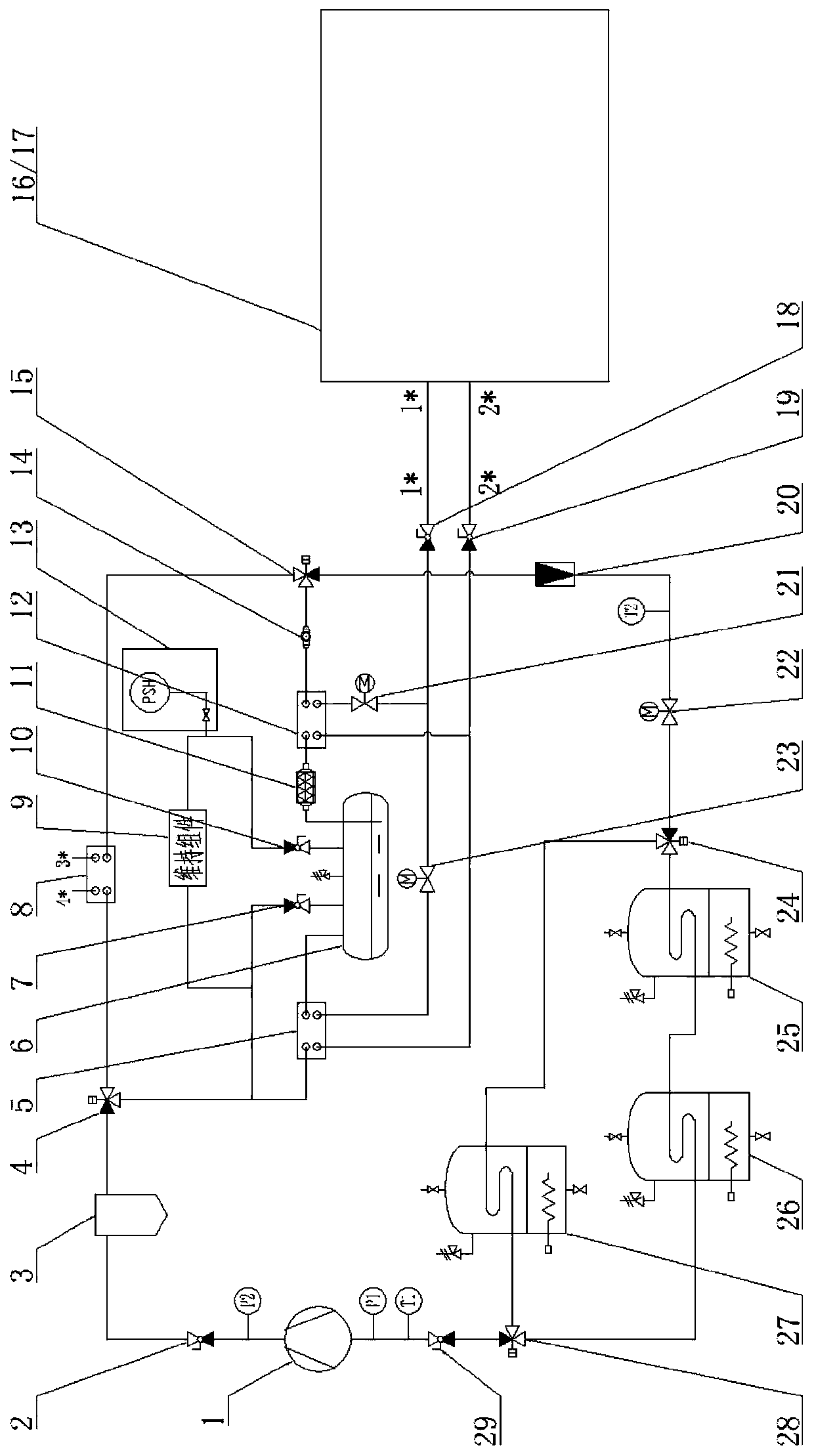

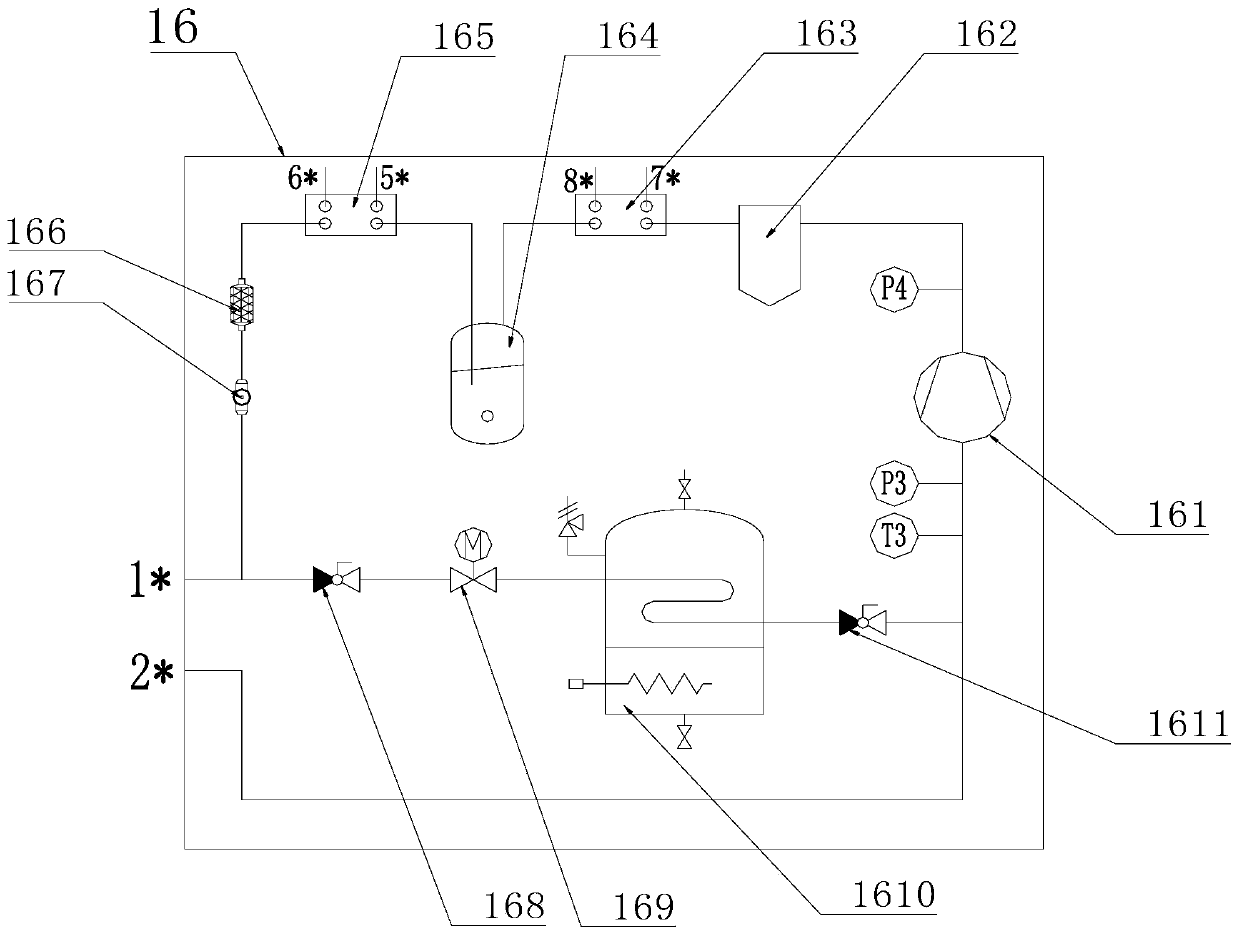

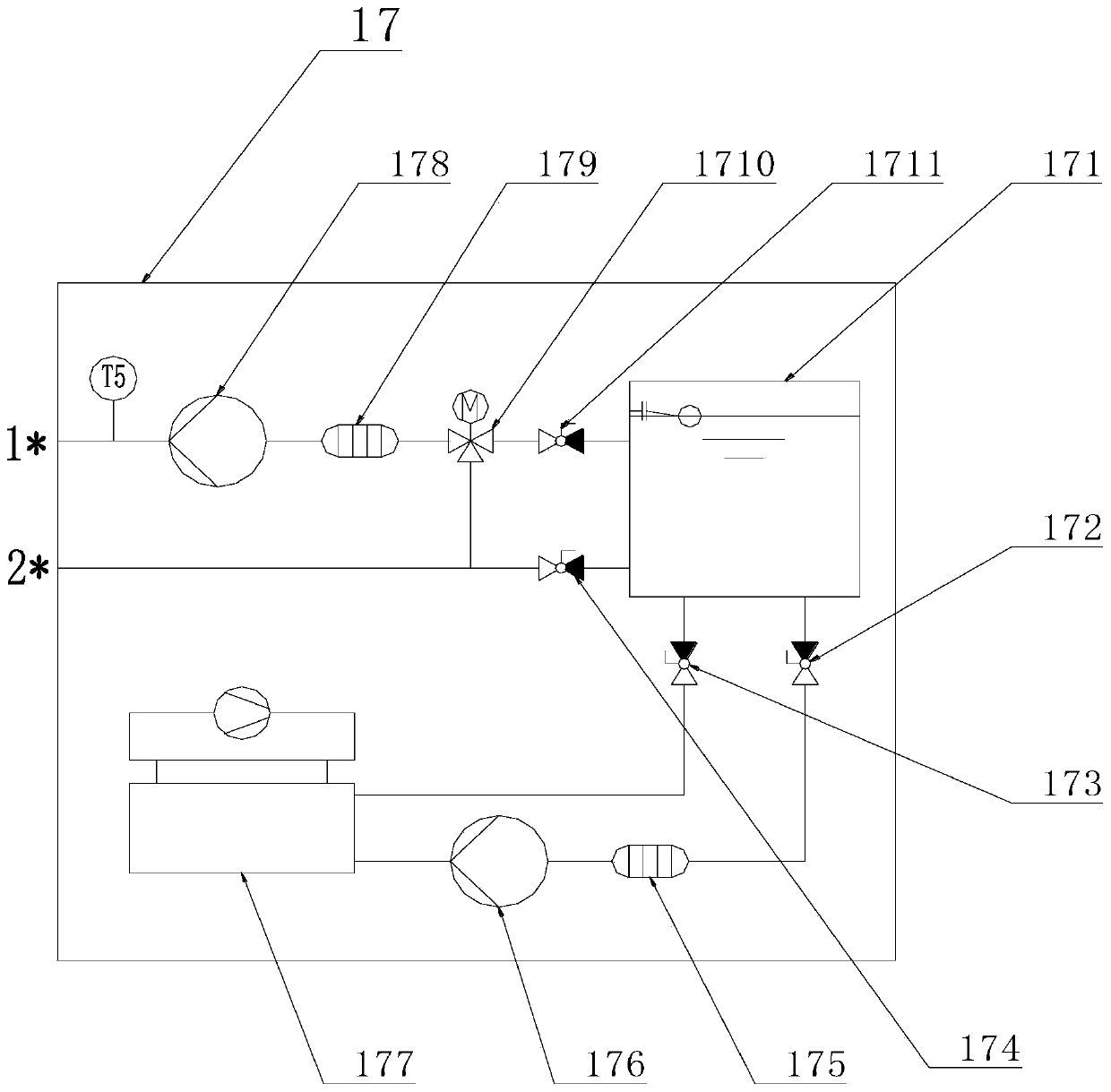

[0057] Such as figure 1 As shown, the carbon dioxide compressor performance test system with trans / subcritical test function includes a test circuit formed on the main pipeline with the tested carbon dioxide compressor 1, and the test circuit includes the first switching valve 4, the second The switching valve 15, the third switching valve 24, the fourth switching valve 28, the first switching valve 4 and the second switching valve 15 are provided with a transcritical cycle gas cooling section and a subcritical cycle condensing section connected in parallel, the first Between the third switching valve 24 and the fourth switching valve 28, a transcritical cycle evaporation section and a subcritical cycle evaporation section connected in parallel are arranged, and an adjustment and measurement component is also arranged on the main line. The first switching valve 4 , the second switching valve 15 , the third switching valve 24 and the fourth switching valve 28 are all three-way ...

Embodiment 2

[0076] Such as figure 1 As shown, the carbon dioxide compressor performance test system with trans / subcritical test function includes a test circuit formed on the main pipeline with the tested carbon dioxide compressor 1, and the test circuit includes the first switching valve 4, the second The switching valve 15, the third switching valve 24, the fourth switching valve 28, the first switching valve 4 and the second switching valve 15 are provided with a transcritical cycle gas cooling section and a subcritical cycle condensing section connected in parallel, the first Between the third switching valve 24 and the fourth switching valve 28, a transcritical cycle evaporation section and a subcritical cycle evaporation section connected in parallel are arranged, and an adjustment and measurement component is also arranged on the main line.

[0077] The transcritical circulation circuit includes the tested carbon dioxide compressor 1, the adjustment and measurement components, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com