Furnace lining detection device of induction furnace body

A detection device, induction furnace technology, applied in electromagnetic measurement device, overall lining, electromagnetic/magnetic thickness measurement, etc., can solve the problems of operator's personal safety hazards, inability to manually judge furnace lining, delay production, etc., to improve safety , Avoid personal safety and equipment failure problems, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

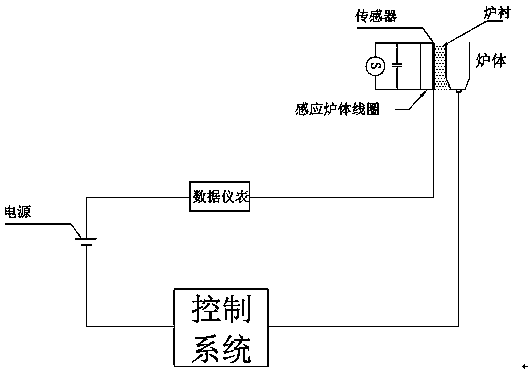

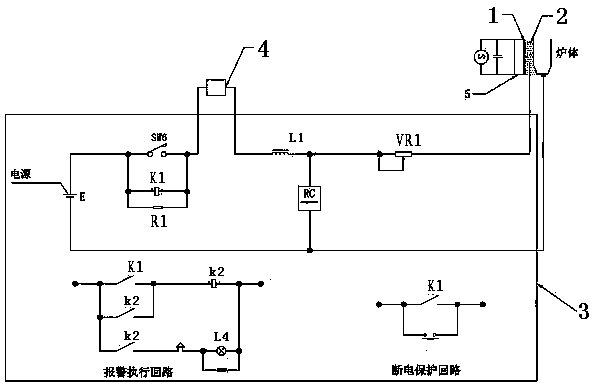

[0016] Such as figure 1 and figure 2 As shown, an induction furnace lining detection device includes a sensor 1, a control system 3, a data instrument 4, and a plurality of wires 5; the sensor 1 is divided into at least two blocks and installed in the lining on the side of the induction furnace, wherein at least A block sensor is connected in series, and two of the block sensors are connected to the control system 3 outside the induction furnace through a wire 5, and a data instrument 4 is connected in series in the control system.

[0017] The sensor 1 is divided into at least two blocks and installed in the furnace lining 2 on the side of the induction furnace body, one of the blocks is connected to a port of the control system 3, and the remaining blocks are connected to the other port of the control system 3 after being connected in series. form a detection loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com