A Method for Measuring Oil Leakage Fault of Porcelain Bushing at Cable Terminal

A cable terminal and measuring cable technology, applied in the field of power cables, can solve the problems such as the oil level liquid level detection scheme of the ceramic sleeve terminal of the power cable that has not yet appeared.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below:

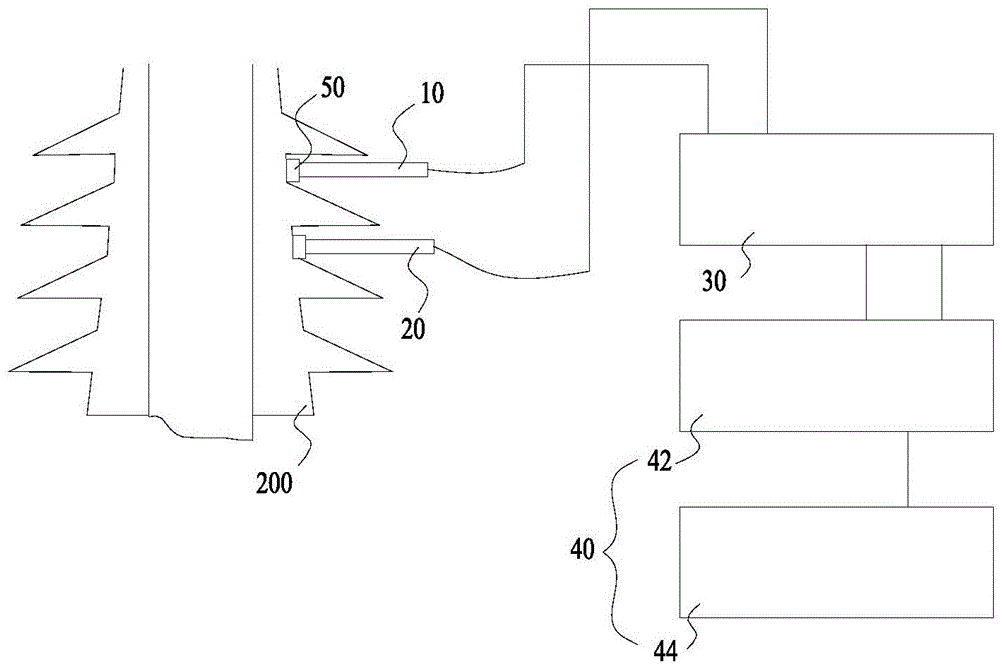

[0022] Such as figure 1 As shown, the device for measuring the oil leakage fault of the porcelain bushing 200 of the cable terminal of the present invention includes a first probe 10 , a second probe 20 , a detection wave generator and receiver 30 and a computing unit 40 . The first probe 10 and the second probe 20 are connected to the detection wave generator and receiver 30 through wires. The generator and receiver 30 generate electric pulse signals to synchronously excite the first probe 10 and the second probe 20 to make the first probe 10 and the second probe 20 generate detection waves. In this implementation, the detection wave is an ultrasonic longitudinal wave, and the first probe 10 and the second probe 20 adopt a single-shot and single-receive working mode. The first probe 10 and the second probe 20 are coupled to the outer wall of the cable terminal ceramic bushing 200 through a silica g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com