Double-loop sequence control circuit

A sequence control, double-loop technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of many connections between screens, inconvenient maintenance, high cost, etc., to achieve reliable operation, convenient maintenance, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

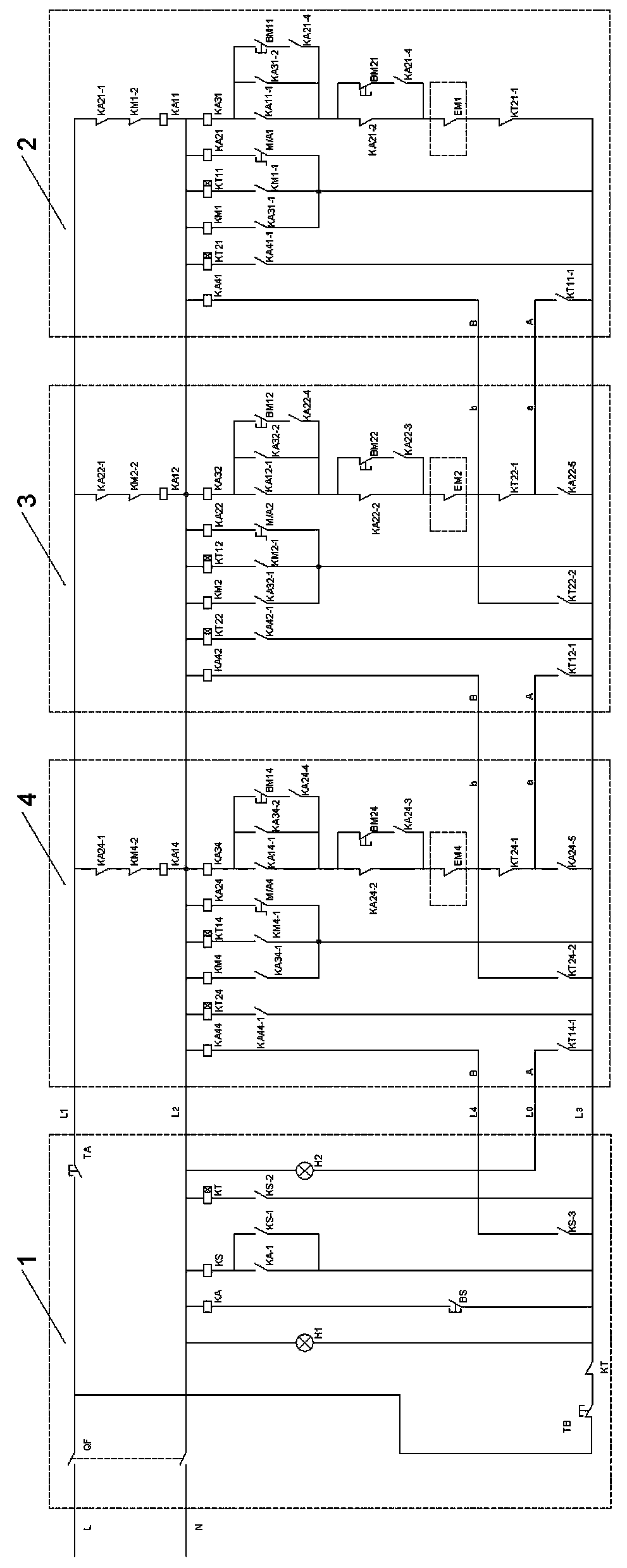

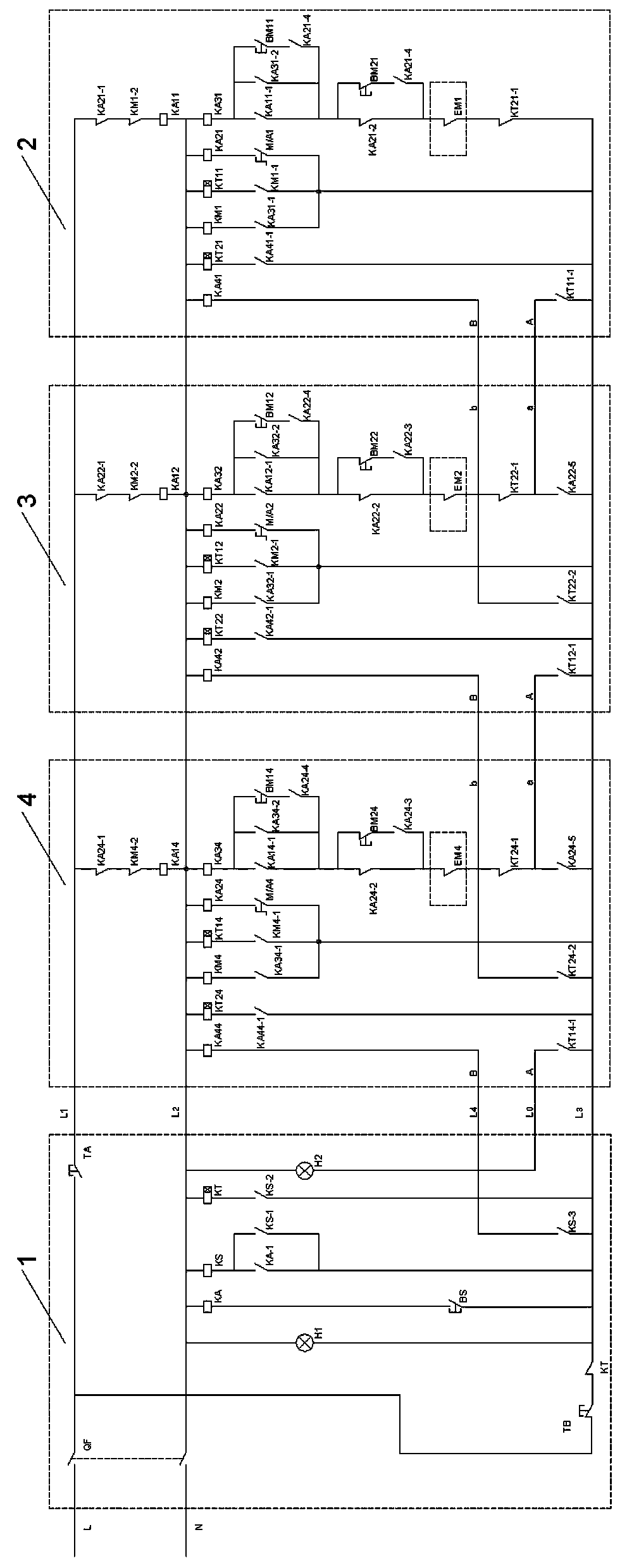

[0014] A double-loop sequence control circuit, which includes a main control box 1 and a sub-control box controlled by the main control box to start and stop, the sub-control box is composed of a first action box 2, at least one secondary action box 3 and a final action box 4, And the first moving box is the sub-control box of the highest level, and the last moving box 4 is the sub-control box of the lowest level. When opening the action, it acts sequentially from the first moving box to the last moving box.

[0015] A switch QF, a start button TA and a stop button TB are set in the main control circuit of the active box 1, wherein the switch QF is set between the L line and the N line of the three-phase electricity; the start button TA and the stop button TB are respectively set on the L line superior. The above-mentioned main control circuit is connected with the starting circuits of the first moving box 2 , the secondary moving box 3 and the last moving box 4 . Each starti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com