Superconducting motor with ultra-low loss

A superconducting motor, ultra-low technology, applied in electrical components, electromechanical devices, etc., can solve the problems of large AC loss, large copper consumption, etc., to achieve the effect of improving power density, low cooling requirements, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

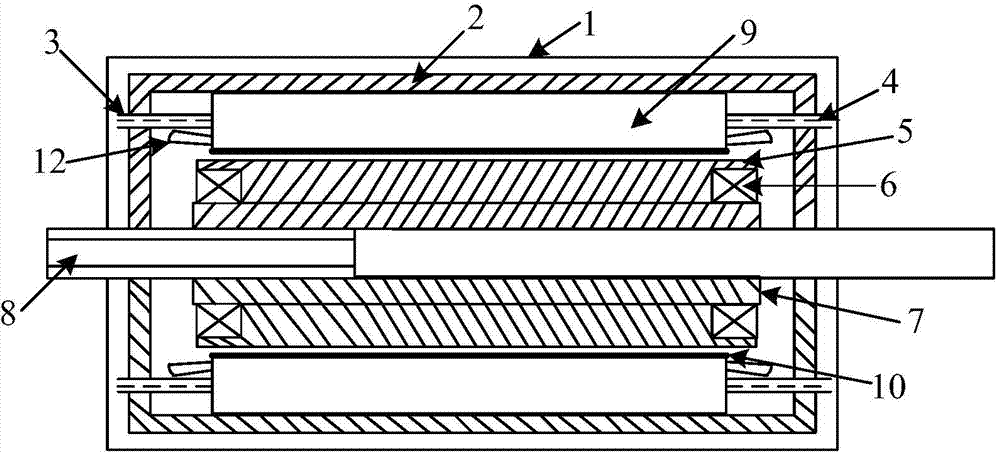

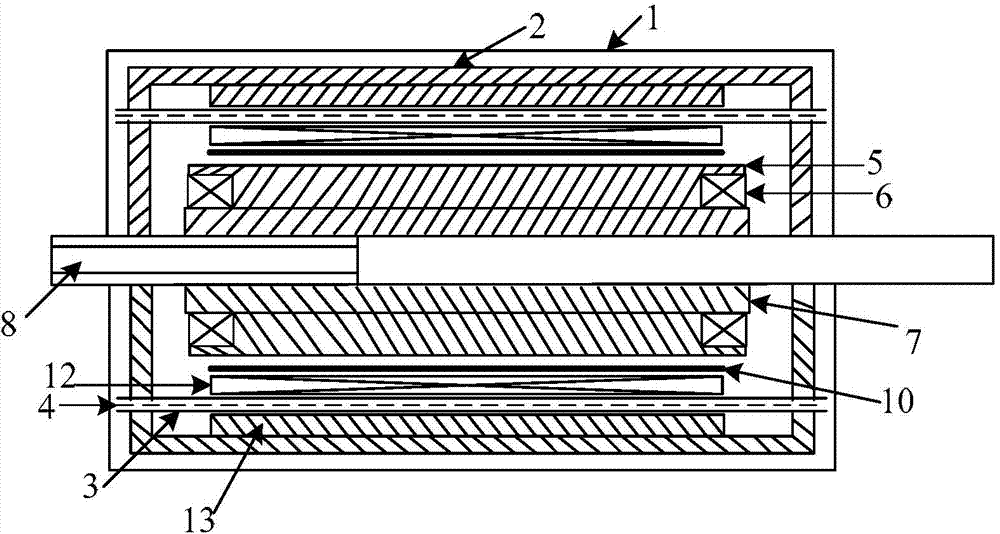

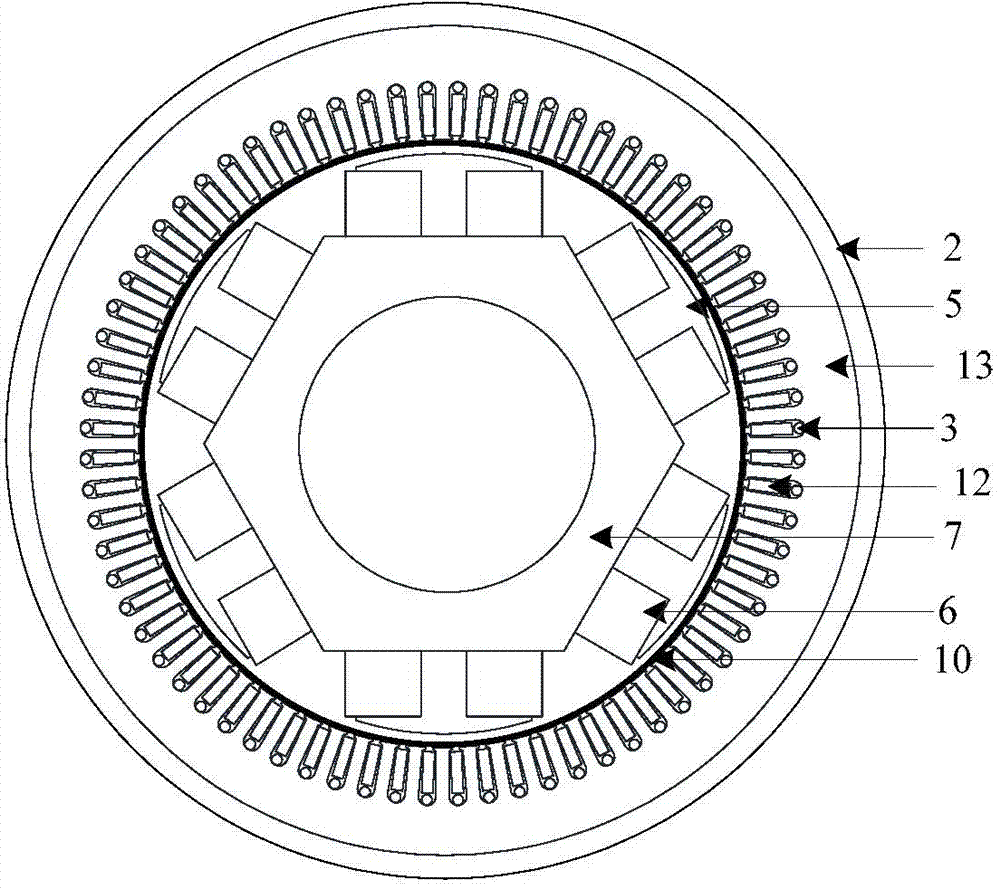

[0024] The present invention will be further explained below in conjunction with the drawings.

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show a superconducting motor with ultra-low loss, including a casing 2, a stator 9 and a rotor 11. The rotor 11 has a coreless structure and is mainly composed of pole shoes 5. , The rotor support 7 and the hollow shaft 8 are composed of a field winding 6 wound on the pole piece 5, the field winding 6 is a superconducting coil; the stator 9 is mainly composed of an armature winding 12 and a stator core 13, in the stator 9 A cooling pipe 3.1 is provided at the bottom of each stator slot. The two ends of the cooling pipe 3.1 are provided with an isolation sleeve 3.2. The same end of all cooling pipes 3.1 is connected to a manifold 3.3. All cooling pipes 3.1 are the same The other end is connected to another bus pipe 3.3; the casing 2 includes a casing 2.1, a spiral tube 2.2 is wound on the outside of the casing 2.1, and the casing 2 is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com