Automatic Control Method of Resistance Furnace Temperature Based on Queue Model

A resistance furnace and model technology, applied in temperature control using digital devices, temperature control using electric methods, etc., can solve problems affecting reliability, low cost of components, high cost, etc., and achieve easy maintenance, high reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

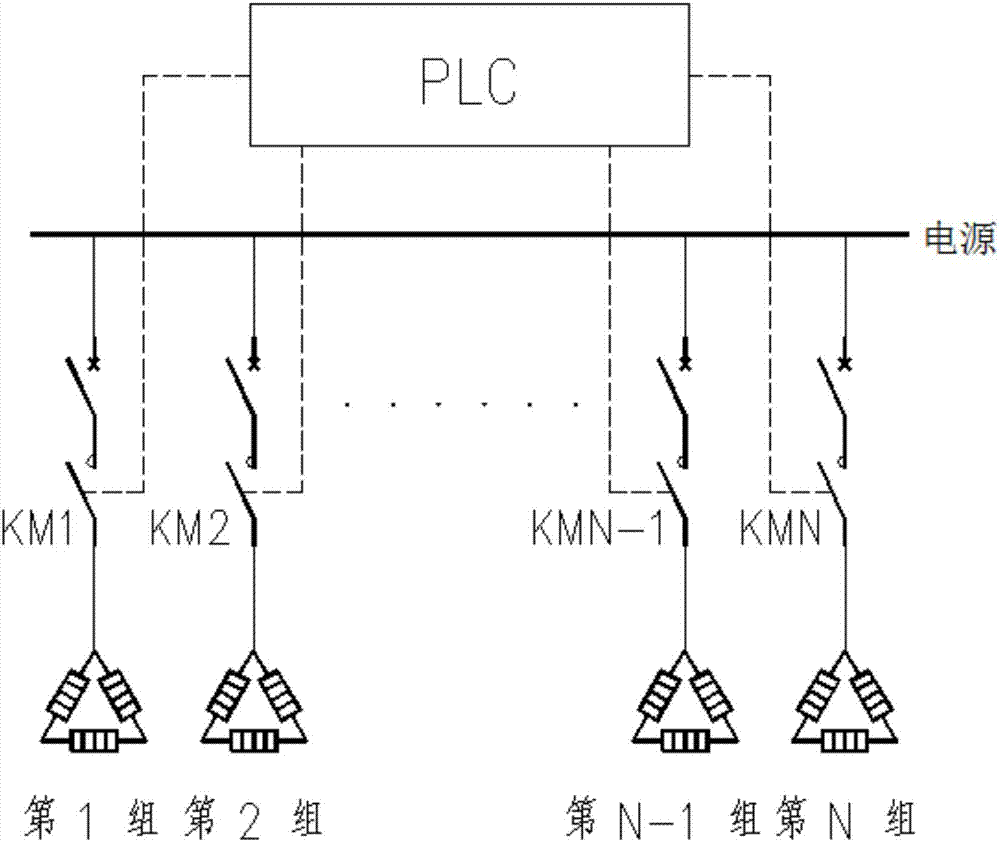

[0031] Such as figure 1 As shown, the present embodiment provides a method for automatically controlling the temperature of a resistance furnace based on a queue model, which includes the following steps:

[0032] (1) Evenly group all the heating devices in a single resistance furnace into N groups according to the heating power. Any group of heating devices is connected to the power supply through a switching device, and all switching devices are controlled by a control device. ;

[0033] (2) Define the set temperature input from the control device as Tset, define the measured temperature collected from the control device as Tact, define the resection temperature of any group of heating devices as ΔTh, and define the input of any group of heating devices The aliquot temperature is ΔT1;

[0034] (3) Calculate the number of groups required to put in or remove the heating device. When TactTset, define the group number required to remove the heating device as E ,in,

[0035] ...

Embodiment 2

[0050]This example provides an application of the method in Example 1 in a resistance furnace with a rated power of 2500kW and below. Due to the limited capacity of the distribution transformer, the capacity of a single resistance furnace generally does not exceed 2500kW. When the resistance When the total capacity of the furnace exceeds 2500kW, it is generally divided into two or more units that work at the same time and are powered by different distribution transformers respectively. Through this example, it can be seen that the method in Example 1 can be better applied to existing furnaces with various power resistance furnace.

[0051] Considering the installation size and cost of the switching devices in the cabinet, the rated current of the switching devices is preferably no more than 400A. Therefore, when grouping, the power of each group of heating devices is preferably no more than 210kW. From the above, it can be seen that in the resistance furnace with a rated power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com