Combined water cooling plate

A water-cooled plate and combined technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of water-cooled plate leakage, high welding cost, and failure to meet the use requirements, so as to reduce processing costs, improve safety, and facilitate normal operation. The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

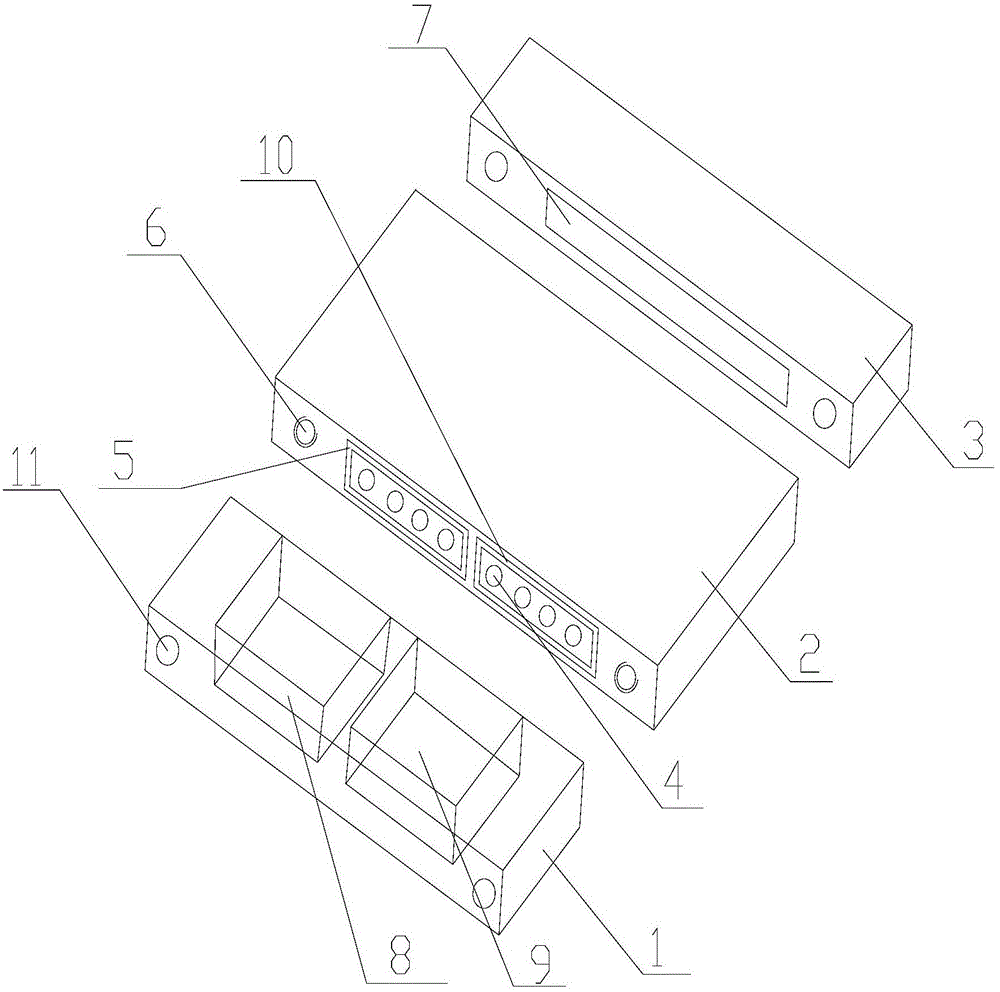

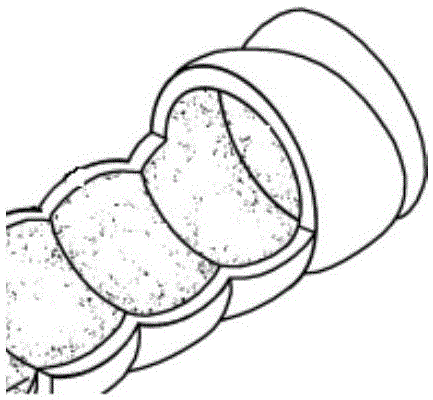

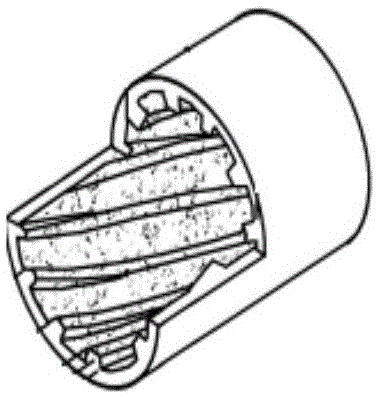

[0021] Example 1, such as Figure 1-Figure 5 As shown, a combined water-cooled plate includes: collecting chamber I1, main cavity 2 and collecting chamber II3; one end of the main cavity 2 is provided with collecting chamber I1, and the other end is provided with collecting chamber II3, It is characterized in that: the collecting chamber I1, the main chamber body 2 and the collecting chamber II3 of the separate structure are fastened together by bolts passing through the through hole 11, and realize rapid assembly and make samples; in order to ensure normal operation and On the premise of prolonging the working life, the high cost of brazing is avoided. This structure can conveniently adjust the channel arrangement according to different working conditions such as different heat dissipation and resistance requirements, and the two collecting chambers can be combined with different main The cavity is combined to realize the modular production of the water-cooled plate, which ov...

Embodiment 2

[0024] Example 2, such as Figure 1-Figure 5 As shown, a combined water-cooled plate includes: collecting chamber I1, main cavity 2 and collecting chamber II3; one end of the main cavity 2 is provided with collecting chamber I1, and the other end is provided with collecting chamber II3, It is characterized in that: the collecting chamber I1, the main chamber body 2 and the collecting chamber II3 of the separate structure are fastened together by studs, and two threaded holes 6 are respectively opened at the opposite ends of the main chamber body 2 , the threaded holes 6 on each side are respectively connected with the through-holes 11 on the collecting chamber I1 and collecting chamber II3 through studs for fastening and installation, which is convenient for installation and disassembly. According to the heat of the water cooling plate It is more convenient to change the layout of channel 4 according to the requirements of resistance, flow resistance and installation space, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com