Module structure, and module construction method

A construction method and structure technology, which is applied in nuclear engineering, industrial buildings, manufacturing reactors, etc., can solve the problems of inability to obtain precision, inability to hang component parts, etc., and achieve the effect of efficient coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Hereinafter, the present invention will be described in detail using embodiments shown in the drawings. The components, types, combinations, shapes, and relative arrangements thereof described in this embodiment are merely illustrative examples unless they are definitive descriptions, and do not limit the scope of the present invention thereto.

[0078] Hereinafter, embodiments of the modular structure and the construction method of the present invention will be described in detail with reference to the drawings.

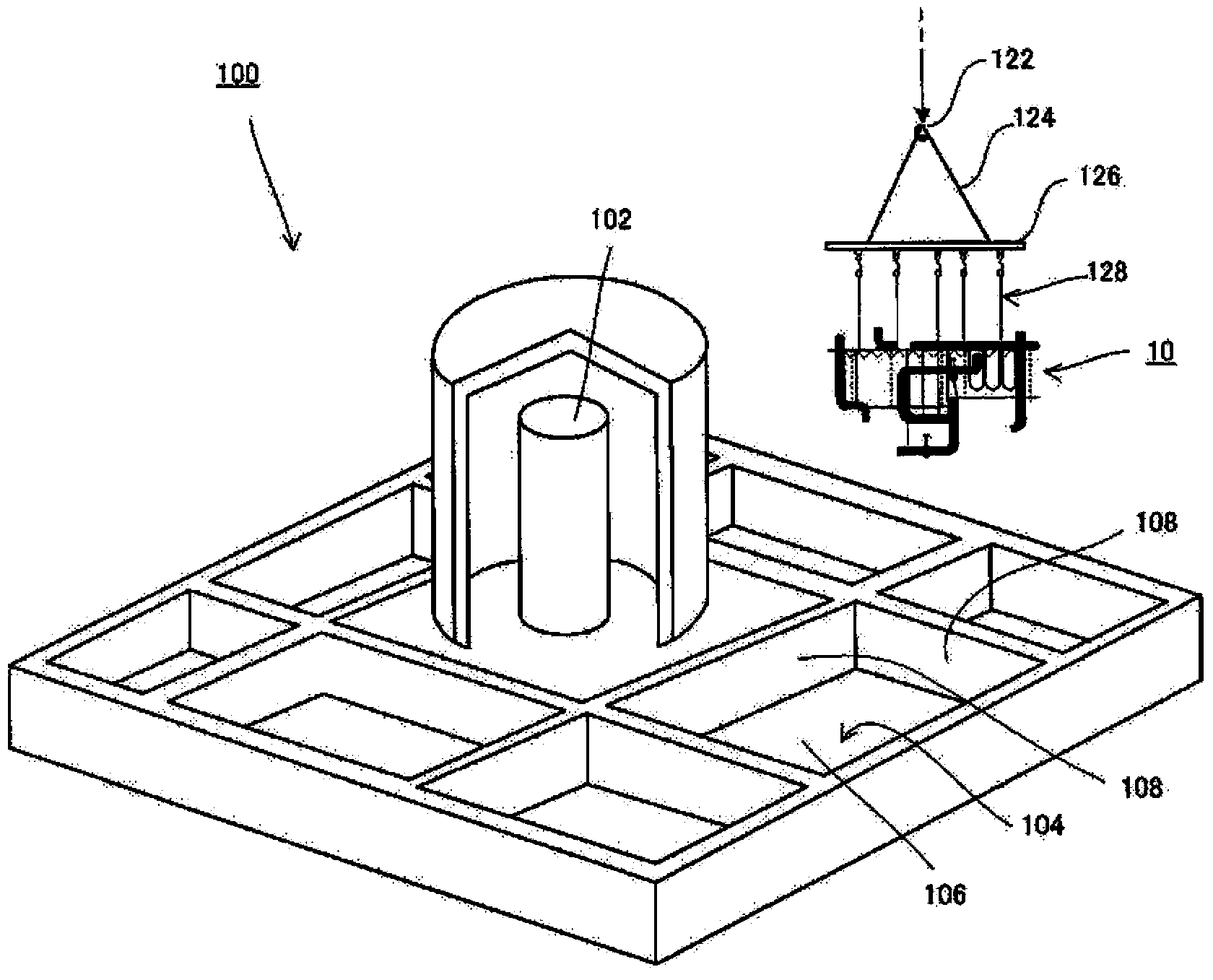

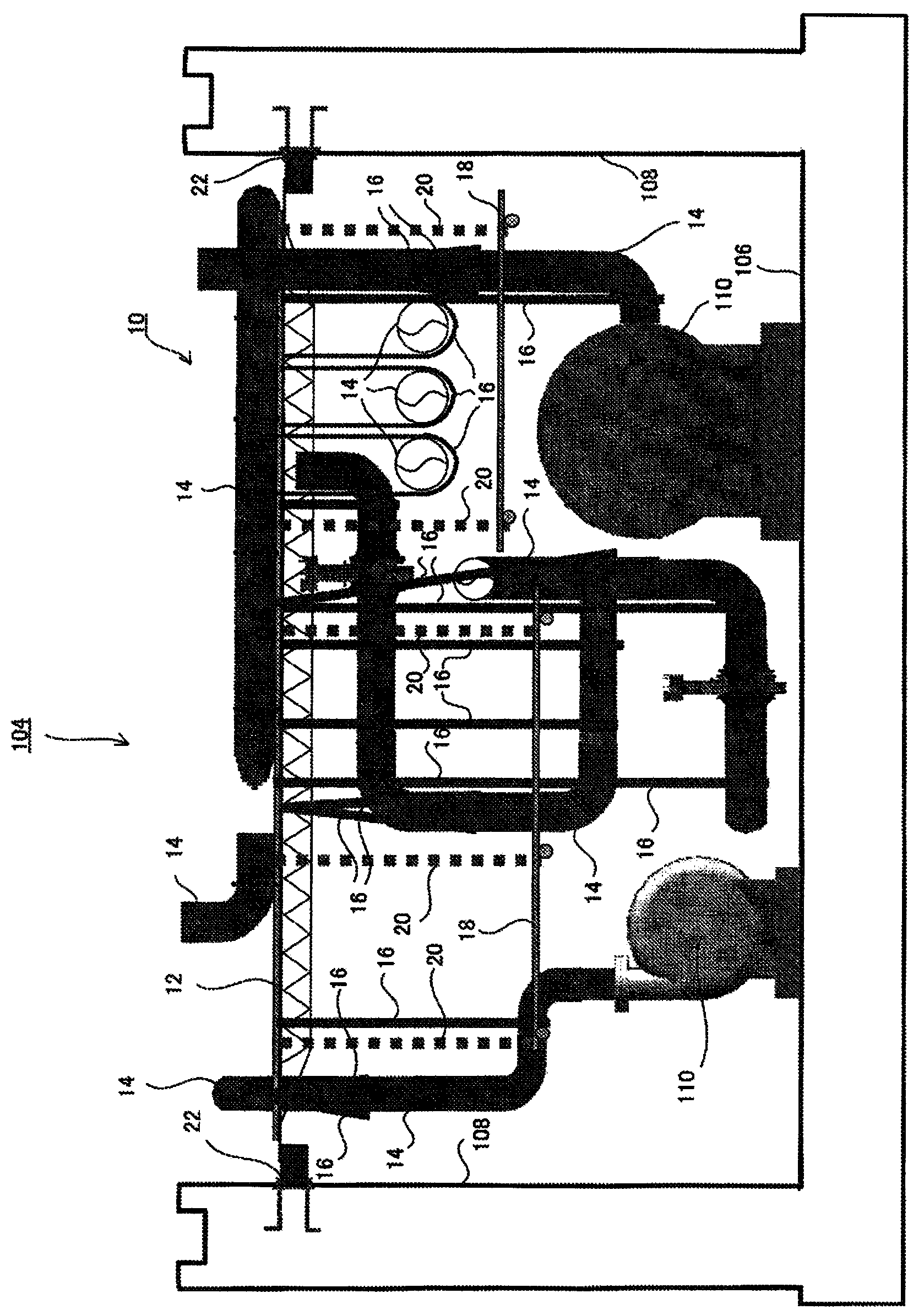

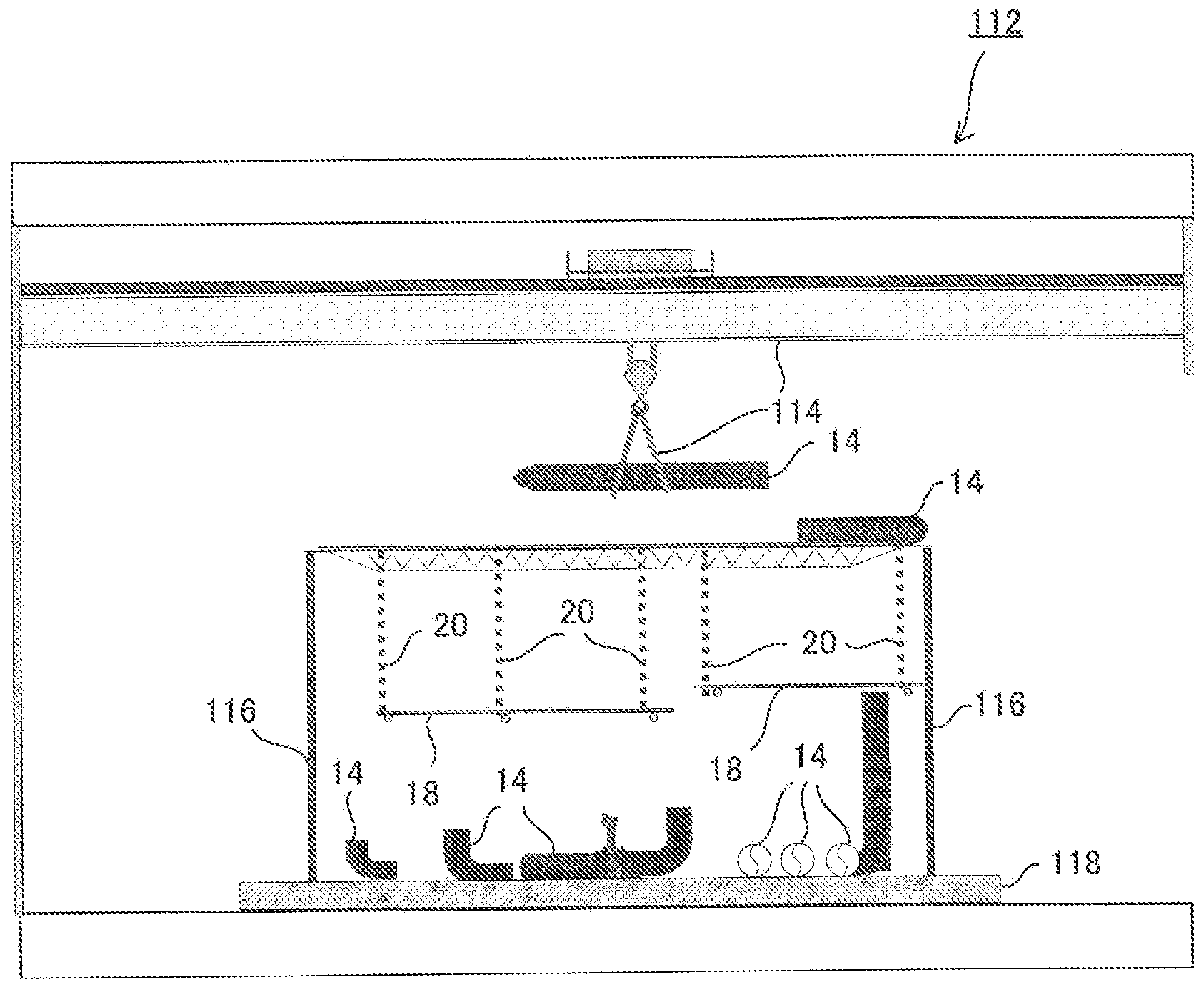

[0079] figure 1 It is an explanatory diagram of a nuclear power plant. figure 2 It is an explanatory drawing of the module structure which concerns on 1st Embodiment. Such as figure 1 As shown, the nuclear power plant 100 will be described below as an example of a factory to which the module structure of the present invention is imported. The nuclear power plant 100 is composed of a plurality of equipment equipment 110 except for the reactor pressure v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com