A Modular Processing Method of Cutting Process Based on Laser Cutting Software

A laser cutting and cutting process technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that the parameters cannot meet the cutting plate and process, and the parameters cannot be set flexibly, and achieve a convenient and fast setting and saving method. , The effect of facilitating copying and transplanting and reducing the probability of burning corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below according to the accompanying drawings.

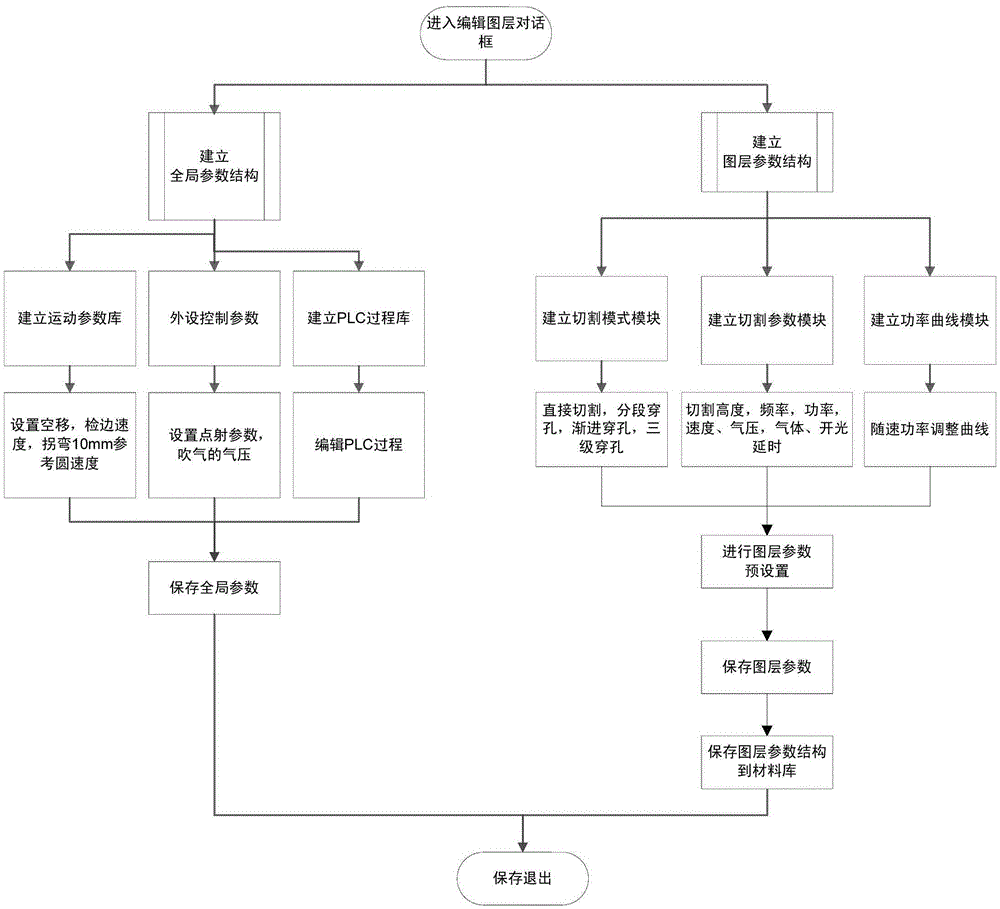

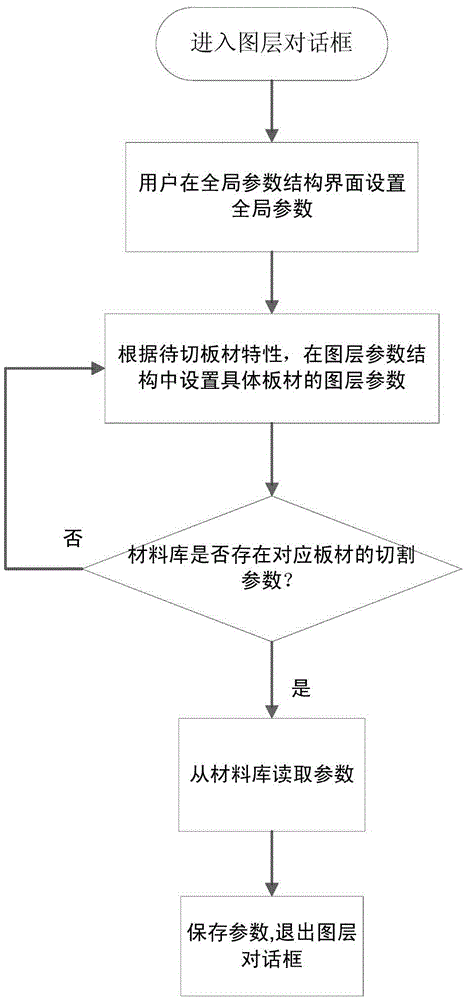

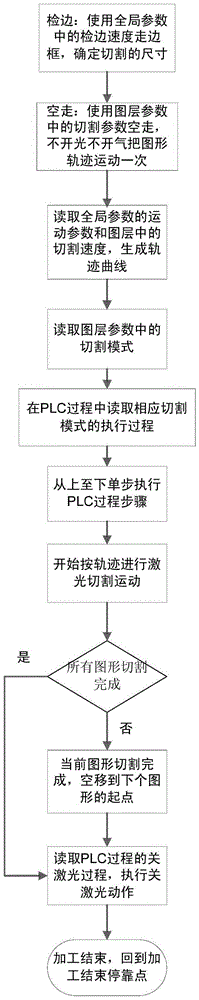

[0028] Such as figure 1As shown, the CypCut laser cutting software is used for layer editing, and then the plate cutting process is performed. The processing steps of the layer editing described are as follows: (1) enter the edit layer dialog box; (2) establish the global parameter structure (3) Save the global parameter structure; (4) establish the layer parameter structure; (5) pre-set the layer parameters; (6) save the layer parameters; (7) save the layer parameter structure to the material library; (8) exit; The establishment of the global parameter structure described above is respectively provided with the establishment of a motion parameter library, peripheral control parameters, and the establishment of a PLC process library. In the described motion parameter library, the 10mm reference circle speed for space movement, edge detection, and turning is set respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com