Automatic decimal alignment mounting machine

An automatic alignment and installation machine technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of lower product quality, inaccurate alignment, and low work efficiency, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

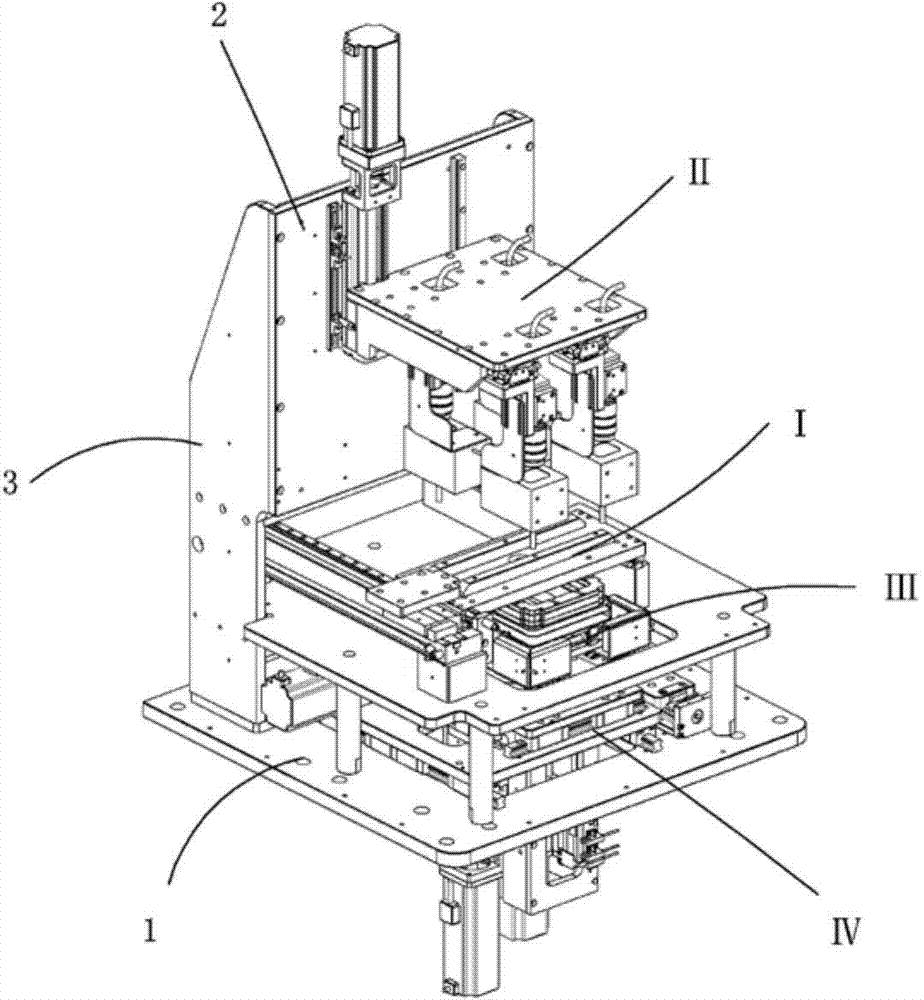

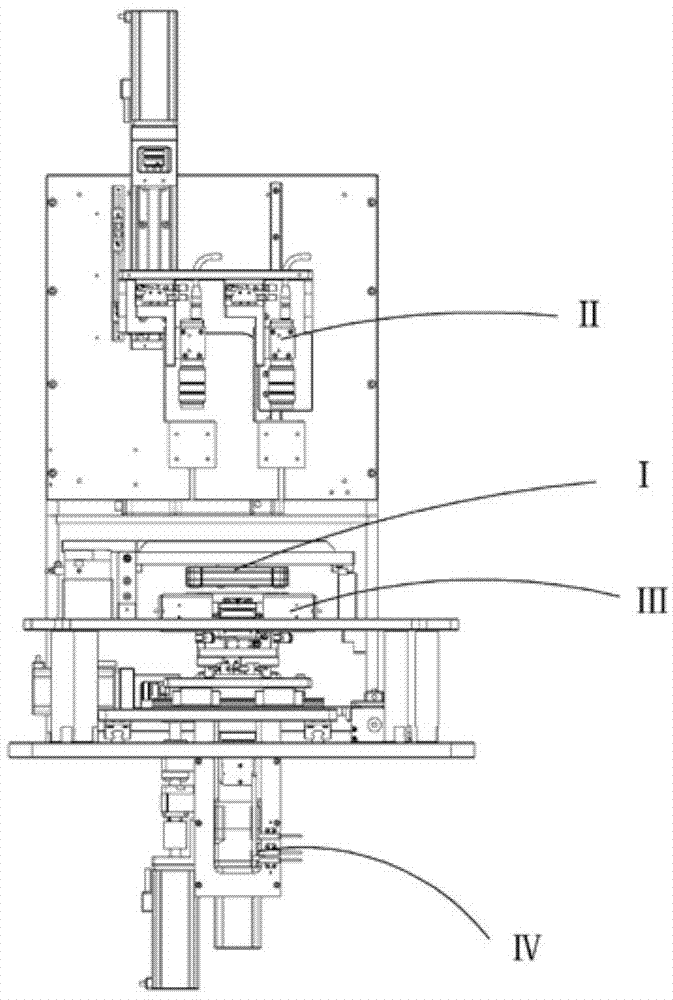

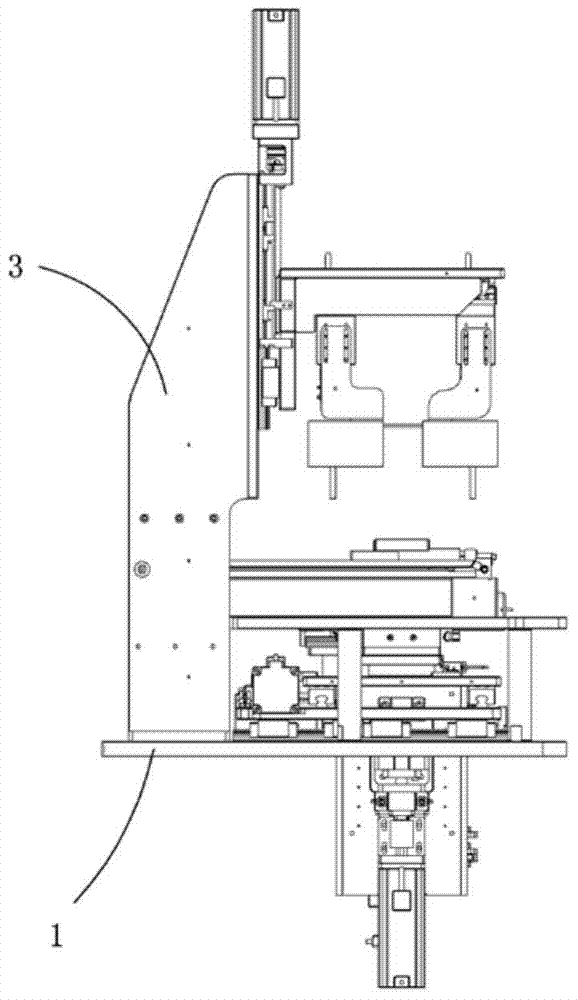

[0041] Examples, see attached figure 1 , an automatic alignment installation machine, which includes a bottom plate 1, a vertical plate 2, a reinforcing plate 3, a product suction mechanism I, a CCD calibration mechanism II, a carrier mechanism III and a four-axis adjustment mechanism IV, and the vertical plate is installed vertically on The bottom plate, and the vertical plate and the bottom plate are strengthened and fixed by a reinforcing plate; the CCD calibration mechanism is installed on the vertical plate; the product suction mechanism is installed on the upper part of the bottom plate, and the lower part of the CCD calibration mechanism; the four-axis adjustment mechanism includes X Axis mechanism, Y-axis mechanism, Z-axis mechanism and R-axis mechanism, the Y-axis mechanism is installed on the base plate; the X-axis mechanism is installed on the Y-axis mechanism; the bottom of the X-axis mechanism is fixedly connected by four The lifting and fixing plate 92 is surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com