A kind of aziridine cross-linked acrylate resin two-component water-based automotive coating and preparation method thereof

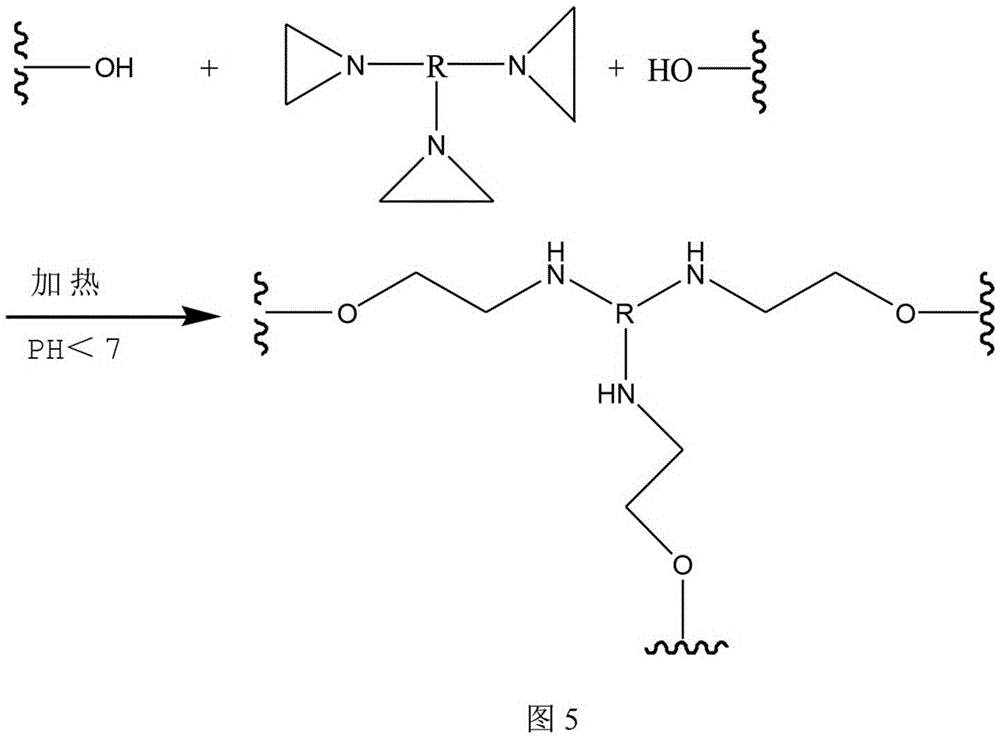

An aziridine crosslinking agent and acrylate technology, which is applied in the field of organic polymer material preparation, can solve the problems of poor water resistance of the cured paint film, large carboxyl and hydroxyl residues in the paint film, and poor compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Table 3 is that in the combination of functional monomer methacrylic acid and functional monomer acetoacetoxyethyl methacrylate in embodiment 1, the amount of acetoacetoxyethyl methacrylate is fixed at 10%, and the amount of methyl methacrylate is gradually increased. The dosage of acrylic acid is 7%, 8%, 9%, 10%, 11% and 14%. 6. There are 6 formulas in total. The 6 formulations of Example 1 all adopt the same synthesis process as follows.

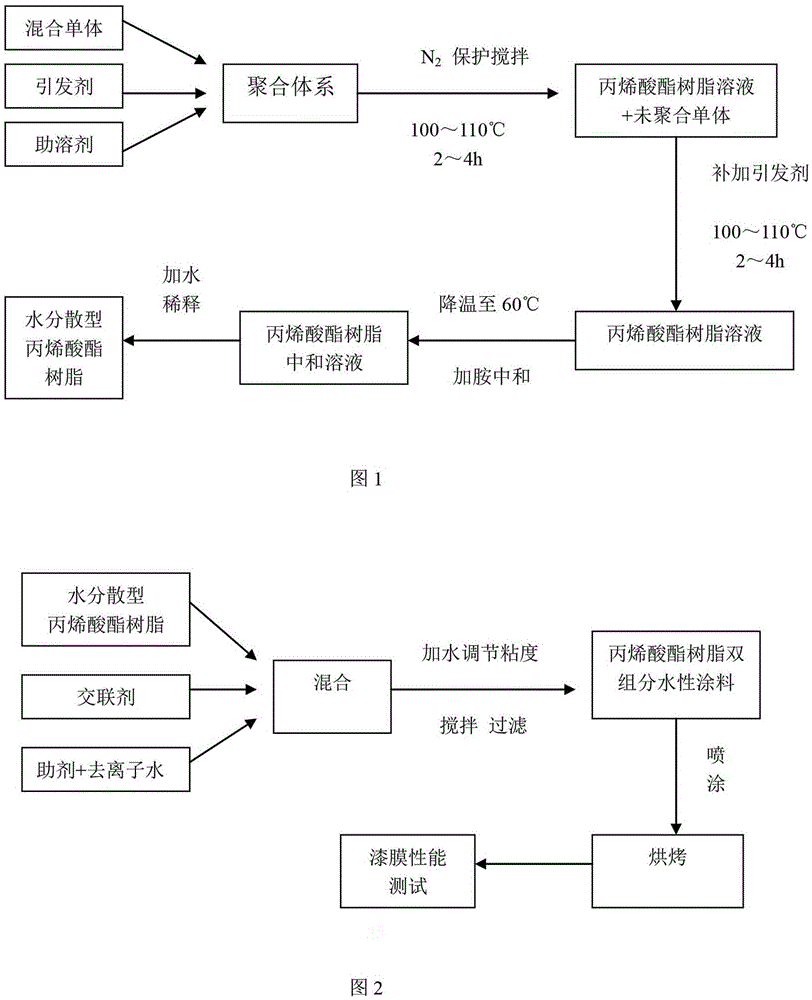

[0044] Add 25 parts of ethylene glycol diethyl ether and 15 parts of isopropanol into a four-necked flask equipped with a stirrer, a condenser, a thermometer and an oil bath heating device. Acrylic acid, methyl methacrylate, styrene, acetoacetoxyethyl methacrylate, butyl acrylate, azobisisobutyronitrile and dodecyl mercaptan were dropped into the four-necked flask with a constant pressure funnel In 4h, drop it within 4h, keep it warm for 1h, dissolve the remaining azobisisobutyronitrile with 10 parts of ethylene glycol diethyl eth...

Embodiment 2

[0053] Table 5 Example 2 changes the basic formula of acrylic acid consumption to synthesize water-dispersible acrylate resin

[0054]

[0055] Table 5 shows that in the combination of functional monomer methacrylic acid and functional monomer acetoacetoxyethyl methacrylate in Example 2, the amount of acetoacetoxyethyl methacrylate is fixed at 10% and gradually increases the amount of acrylic acid 5.5%, 6.5%, 7.5%, 8.5%, 9.5% and 10.5%, while correspondingly reducing the amount of methyl methacrylate to synthesize the feeding formula of water-dispersible acrylate resin, the formula numbers are 7, 8, 9, 10, 11 and 12, a total of 6 recipes. The synthesis process of each recipe is the same.

[0056] According to the technological process of embodiment 1 synthetic water-dispersible type acrylate resin synthetic table 5 numbering is 6 kinds of water-dispersible type acrylate resins of 7~12, prepares aziridine according to the formula of embodiment 1 preparation coating and the ...

Embodiment 3

[0061] Table 7 Example 3 Change the amount of acetoacetoxyethyl methacrylate to synthesize the basic formula of water-dispersible acrylate resin

[0062]

[0063]Table 7 is that in the combination of functional monomer methacrylic acid and functional monomer acetoacetoxyethyl methacrylate in embodiment 3, the amount of methacrylic acid is fixed at 10% and gradually increases acetoacetoxyethyl methacrylate The dosage is 7%, 8%, 9%, 10%, 11% and 14%, and the feeding formula for synthesizing water-dispersible acrylic resin under the condition of correspondingly reducing the dosage of methyl methacrylate at the same time, its formula numbers are in order 13, 14, 15, 16, 17 and 18, a total of 6 recipes. The synthesis process of each recipe is the same.

[0064] According to the technological process of embodiment 1 synthesizing water-dispersible type acrylate resin, synthetic table 7 is numbered as 6 kinds of water-dispersible type acrylate resins of 13~18, prepares aziridine a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap