Long-united bridge widening splicing structure and construction method thereof

A construction method and bridge technology, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., can solve the problem of long (generally 2 to 3 years, some even more than 3 years, standing time of the overall structure of the old bridge bearing cross bridge) Large displacement in direction, affecting the normal use of the bridge, etc., to achieve the effect of short construction period, realization of circular economy development model and sustainable development, good economic benefits and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with specific examples. The processing methods in the following examples, unless otherwise specified, are conventional methods: the raw materials and tools used in the following examples, unless otherwise specified, are commercially available.

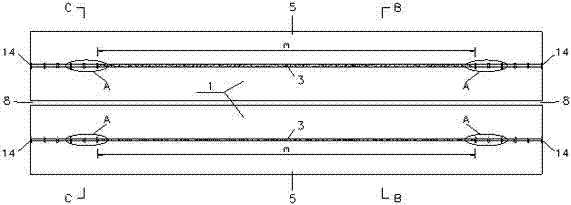

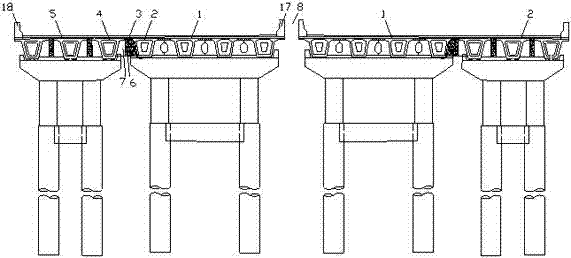

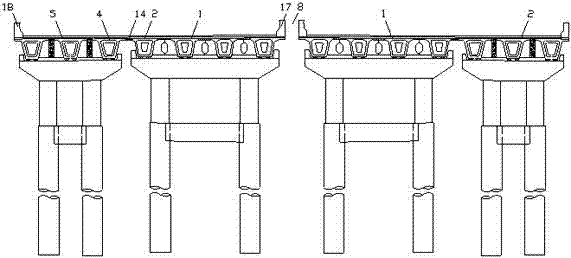

[0043] A widening splicing structure of long-connected bridges, see Figure 1~Figure 6 , including the old bridge 1, the new bridge 5 and the splicing joint, the splicing joint between the old bridge girder 2 and the new bridge girder 4 is composed of a continuous splicing segment and a discrete splicing segment, wherein the continuous splicing segment The cast-in-place wet joint 3 and the diaphragm are connected between the old bridge side girder 2 and the new bridge side girder 4, and above the cast-in-place wet joint are the cast-in-place layer 10 of the new bridge deck, the waterproof layer 13 and the new bridge deck Surface pavement layer 16; the old bridge si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com