Through-flow check valve for chlorine gas

A technology of through-flow, check valve, applied in lift valve, valve details, control valve, etc., can solve the problem that the performance cannot meet the requirements of working conditions, the disc of the check valve cannot be returned well, and the structure is old, etc. problem, to achieve the effect of superior sealing performance, good non-return effect and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

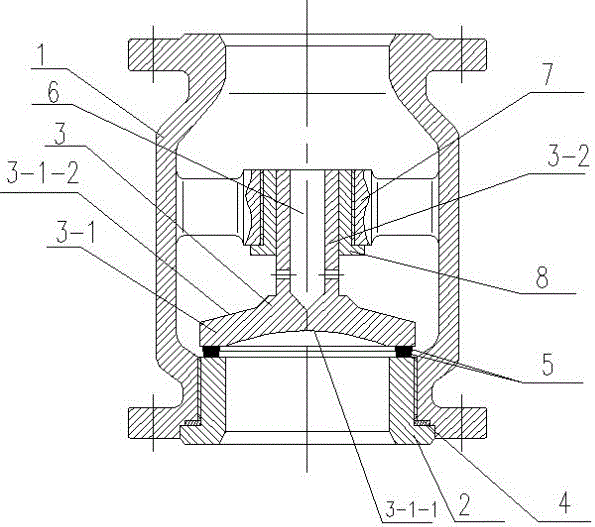

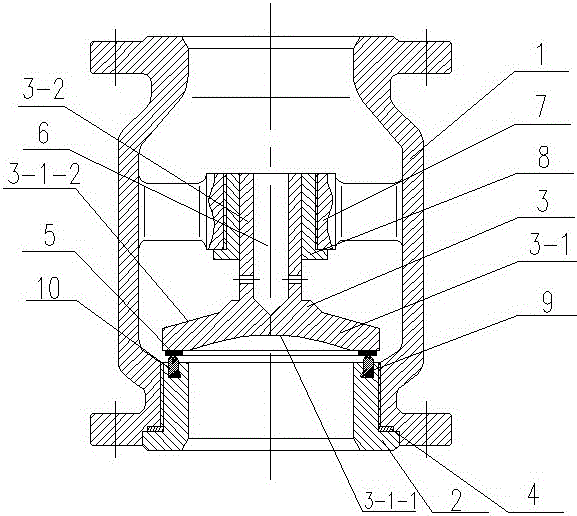

[0011] Such as figure 1 As shown, the present invention includes a valve body 1, a valve seat 2, and a valve clack 3. The valve seat 2 is threadedly connected in the lower end of the valve body 1; a wound gasket 4 is arranged between the valve body 1 and the valve seat 2. The sealing gasket 4 is arranged below the threaded connection of the valve body 1 and the valve seat 2; the valve flap 3 is arranged above the valve seat 2; the valve flap 3 and the valve seat 2 are in a sealed connection, and the valve seat 2 and the valve seat 3 The sealing surface is spray-welded with corrosion-resistant alloy 5; the valve flap 3 includes a valve flap body 3-1 and a valve stem body 3-2. The valve flap stem body 3-2 is arranged above the center of the valve flap body 3-1. A blind hole 6 is provided in the valve clapper body 3-2; the lower surface of the valve clapper body 3-1 is an upwardly convex arch 3-1-1, and the upper surface of the valve clapper body 3-1 is downwardly inclined Slope 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com