Warm air drying device

A drying device, warm air technology, applied in the direction of drying solid materials, progressive dryer, heating to dry solid materials, etc., can solve the problem of inability to keep the bottle body, the outer surface of the bottom of the bottle dry, difficult to transport and store, and the packaging carton is wet And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

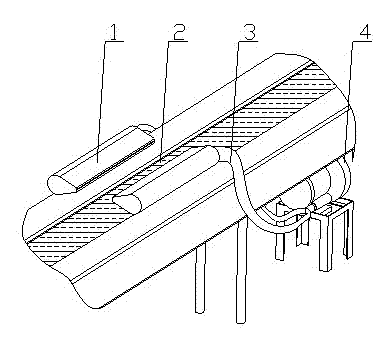

[0008] As shown in the attached figure: a warm air drying device on a pure water production line, including a production line 2, an electric heat source blower 4, an air duct 3, an air outlet 1, an electric heat source blower 4, an air guide pipe 3, and an air outlet 1 in sequence Connect to form two air outlet pipelines, and the two air outlets 1 are respectively placed above the guardrails on both sides of the production line; the air outlets are long strip-shaped boxes with slender openings on them.

[0009] The warm air output by the electric heat source blower 4 enters the air guide pipe 3 through the warm air output port and is sprayed out by the air outlet 1, acting on the water bottles on the pure water production line to dry them quickly and completely, which is convenient for subsequent packing operations. Thereby ensuring that the packing box is not easy to get wet, and is convenient for transportation and storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com