Gas small flow standard device

A standard device, small flow rate technology, applied in the direction of measuring device, test/calibration device, liquid/fluid solid measurement, etc., can solve the problems that the measurement accuracy is greatly affected, and it is difficult to meet the high-precision measurement requirements, so as to achieve accurate pressure measurement , real use value, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

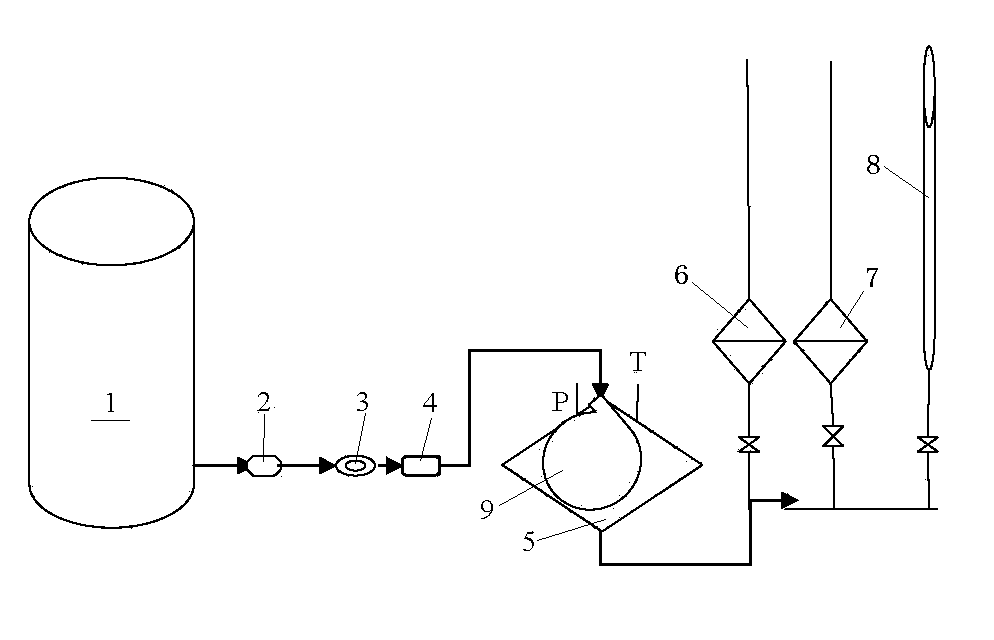

[0028] A small gas flow standard device, such as figure 1 As shown, it includes a surge tank 1, a pressure regulating valve 2, a mass flow controller 3 and a flow meter 4 connected in sequence, and also includes a water storage container 5 and standard measuring devices 6, 7. The water storage container 5 A pipeline is provided to be connected to the tested flow meter 4; and a pipeline is set in the water storage container 5 to be connected to the standard gauges 6, 7, and the bottom surface of the standard gauges 6, 7 is higher than the top of the water storage container 5; the water storage container 5 Built-in air bag or diaphragm 9 to separate the measured gas from water, and the gas side of the air bag or diaphragm is equipped with temperature and pressure measuring gauges.

[0029] A temperature sensor is provided in the water storage container 5 , and a liquid level sensor 8 is provided between the water storage container 5 and the standard gauges 6 and 7 .

[0030] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com