Lens module testing device

A lens module and testing device technology, which is applied in the direction of measuring devices, measuring device casings, and measuring electronics, can solve the problems of misjudgment of measurement results, long test time and low efficiency, and increased labor costs and measurement equipment costs. Achieve the effect of improving detection efficiency, avoiding errors, and improving detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

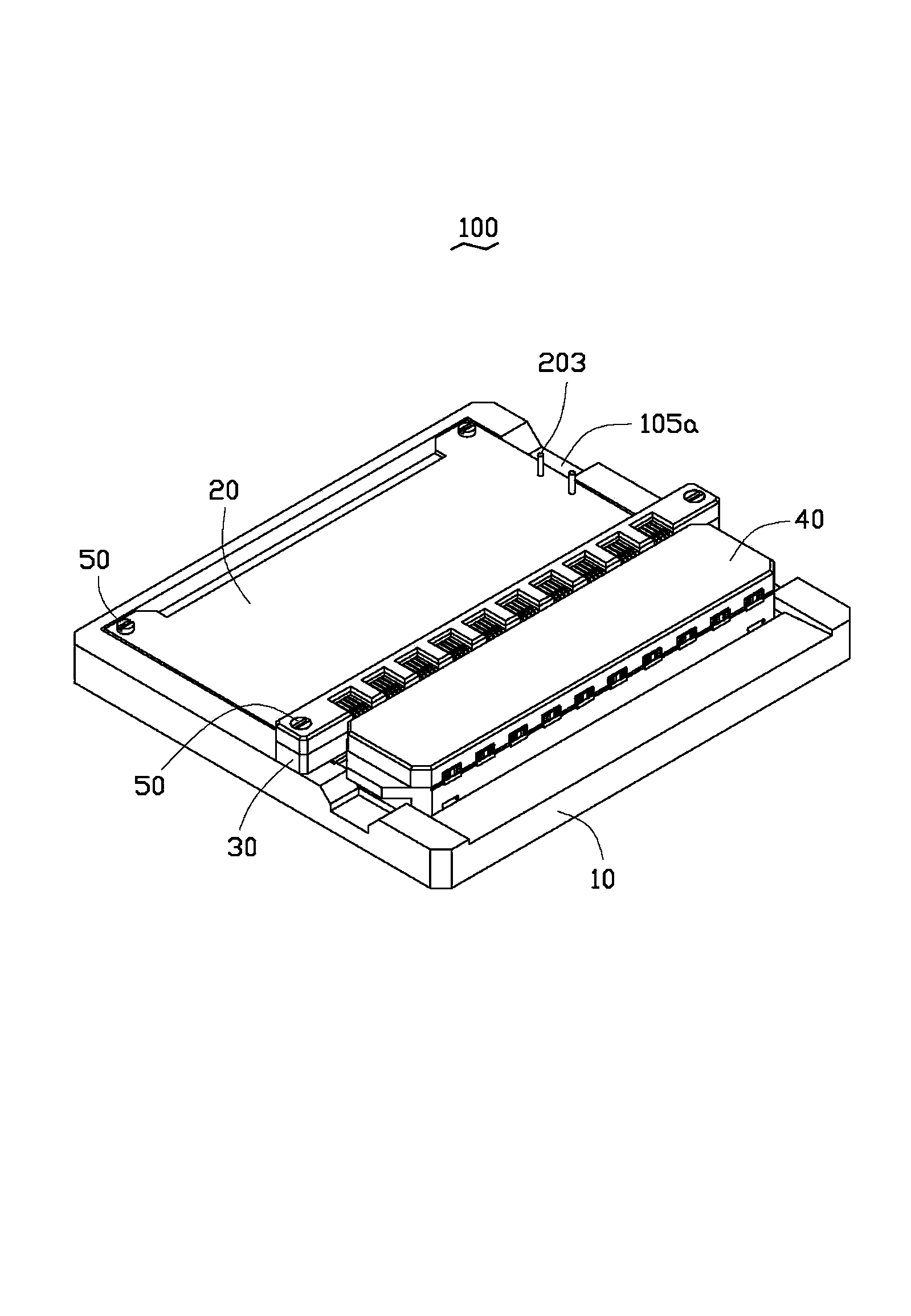

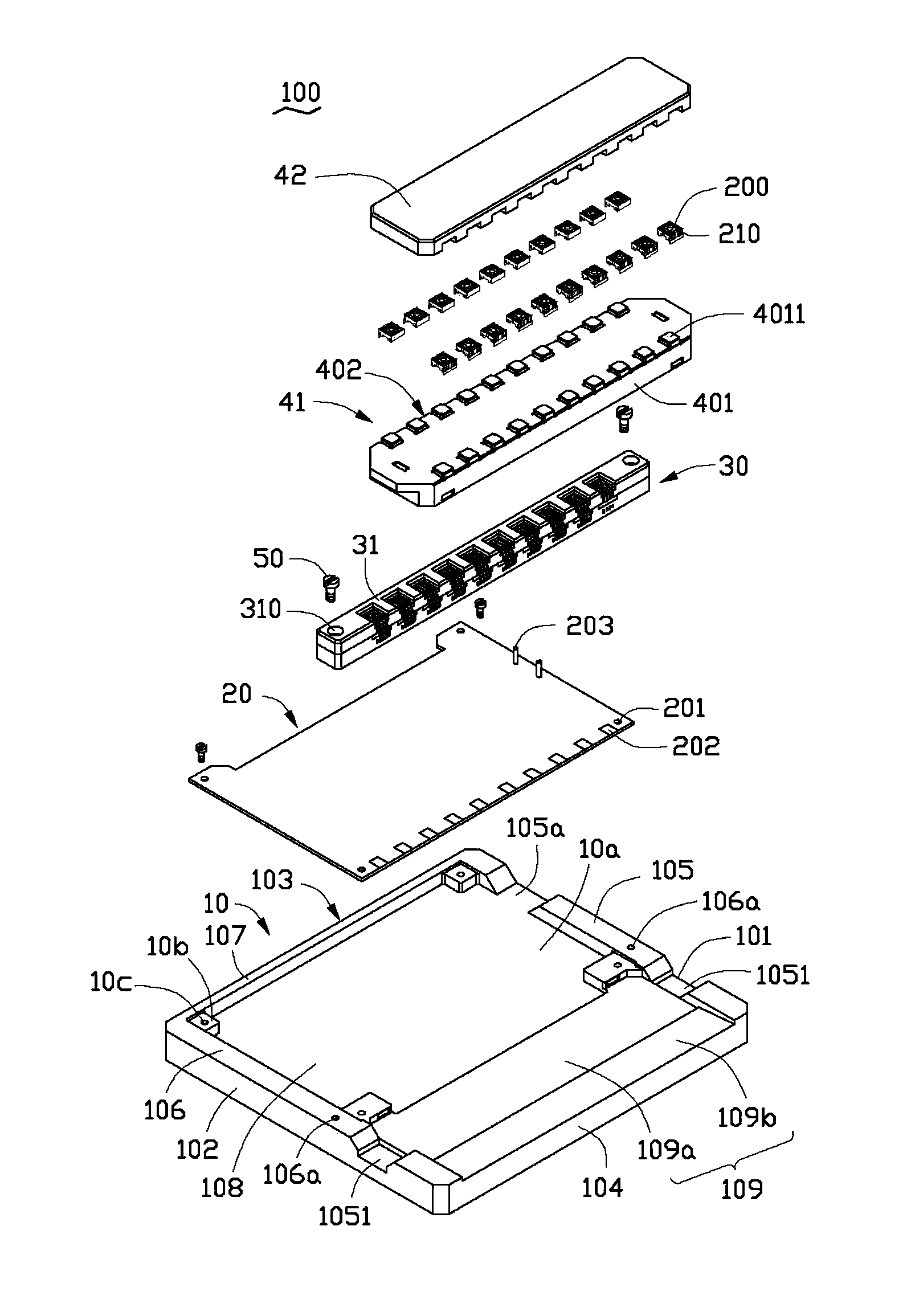

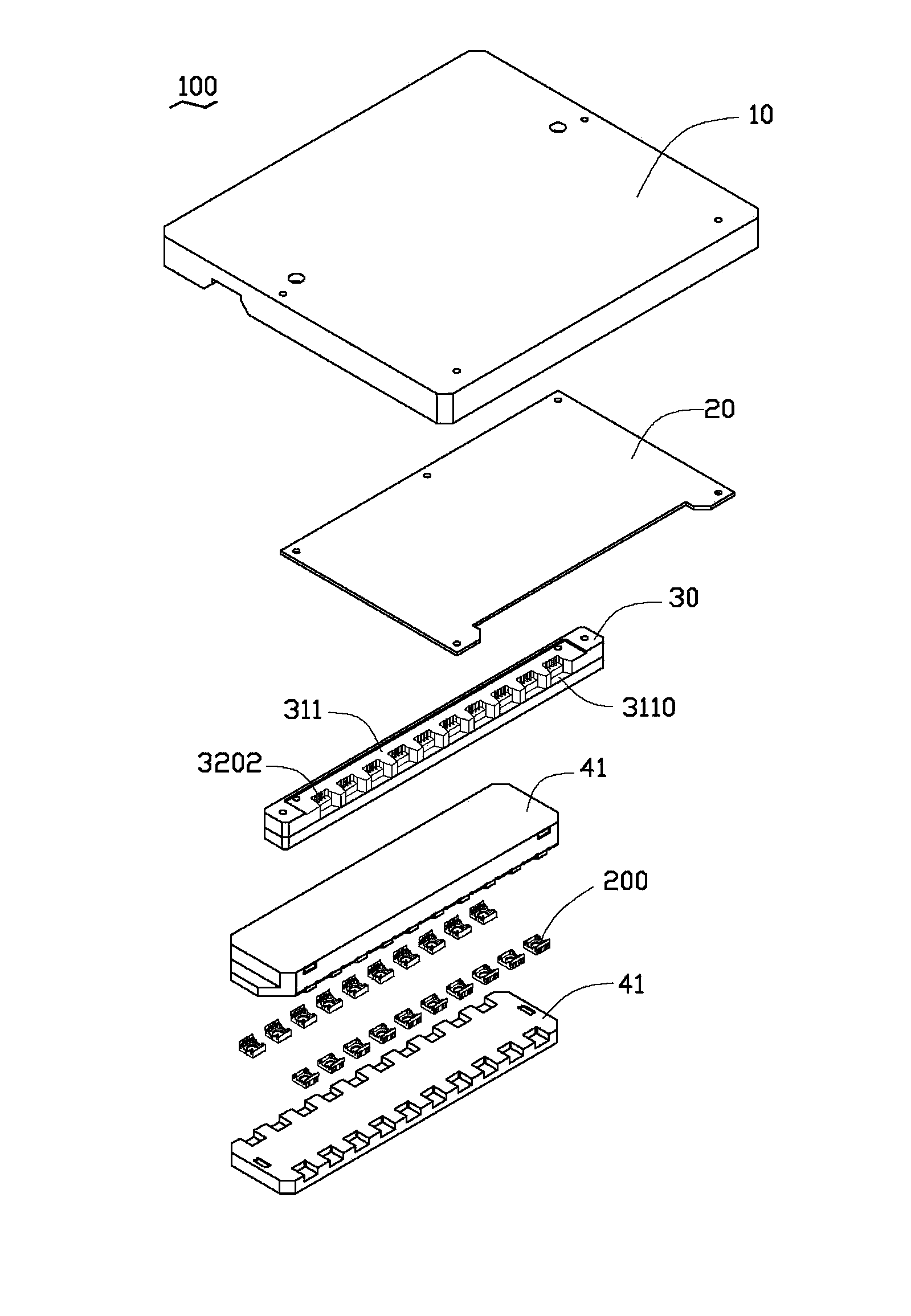

[0018] Please also refer to Figure 1 to Figure 4 , the lens module testing device 100 provided by the embodiment of the present invention is used to test the electrical properties of multiple lens modules 200 , and each of the lens modules 200 is provided with multiple electrical contacts 210 .

[0019] The lens module testing device 100 includes a platform base 10 , a circuit board 20 , a connecting component 30 and a carrying component 40 . The circuit board 20 is carried on the platform base 10 . The connection assembly 30 is fixed on the platform base 10 and electrically connected to the circuit board 20 . The carrying assembly 40 is detachably mounted on and fixed on the connecting assembly 30 for carrying the plurality of lens modules 200 .

[0020] The platform base 10 includes a bearing surface 10a. In this embodiment, the bearing surface 10a is a square structure, which includes a first side wall 101, a second side wall 102 parallel to and opposite to the first si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com