Special eddy current flaw detector of cylinder sleeve

An eddy current flaw detection and cylinder liner technology, which is applied in the field of flaw detection instruments, can solve problems such as low detection efficiency, easy misjudgment, and engine failure, and achieve the effects of improved detection quality, strong versatility, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

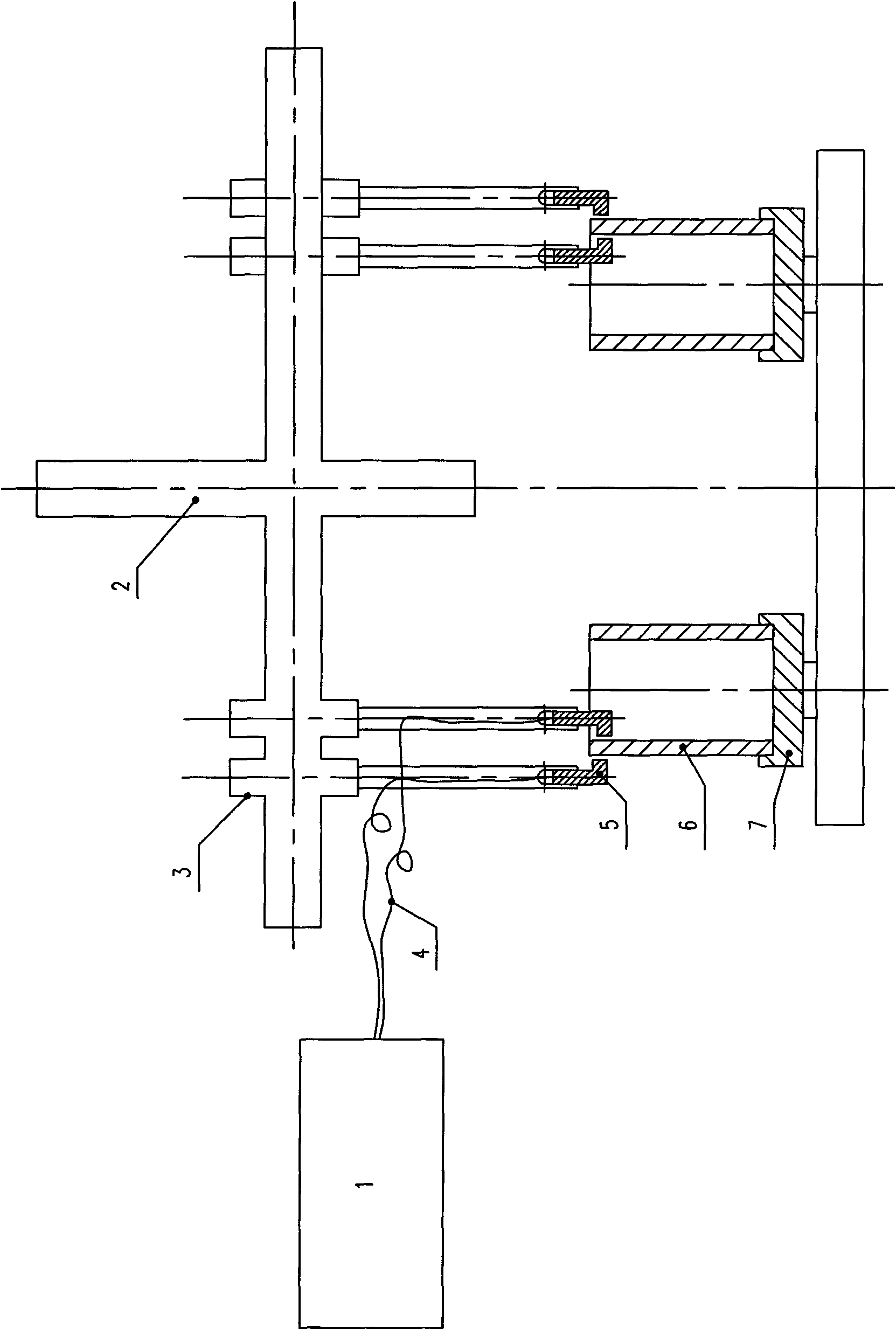

[0013] Such as figure 1 The special eddy current flaw detector for cylinder liner shown in the figure includes eddy current flaw detector 1 and sliding guide rail 2. The sliding guide rail 2 is provided with a probe clamping device 3 that can slide along the sliding guide rail 2, and the clamping positions at the ends of the probe clamping device 3 are respectively The probe 5 of the eddy current flaw detector 1 corresponds to the position of the clamped cylinder liner 6 wall, and the self-centering cylinder liner clamp 7 for clamping the cylinder liner 6 is provided with a rotating mechanism. The main control system of the eddy current flaw detector 1 is also equipped with a defect signal alarm device. The probe clamping device 3 can be adjusted along the direction of the vertical sliding guide rail 2 . The probe clamping device 3 and the sliding guide rail 2 are driven by a servo motor, and the rotating mechanism is driven by a variable-speed variable-frequency motor. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com