Sealing process of smectic liquid crystal display

A liquid crystal display, smectic phase technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of inability to complete the sealing operation, low process efficiency, long pressurization time, etc., to shorten the sealing operation time and flattening effect. Good, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

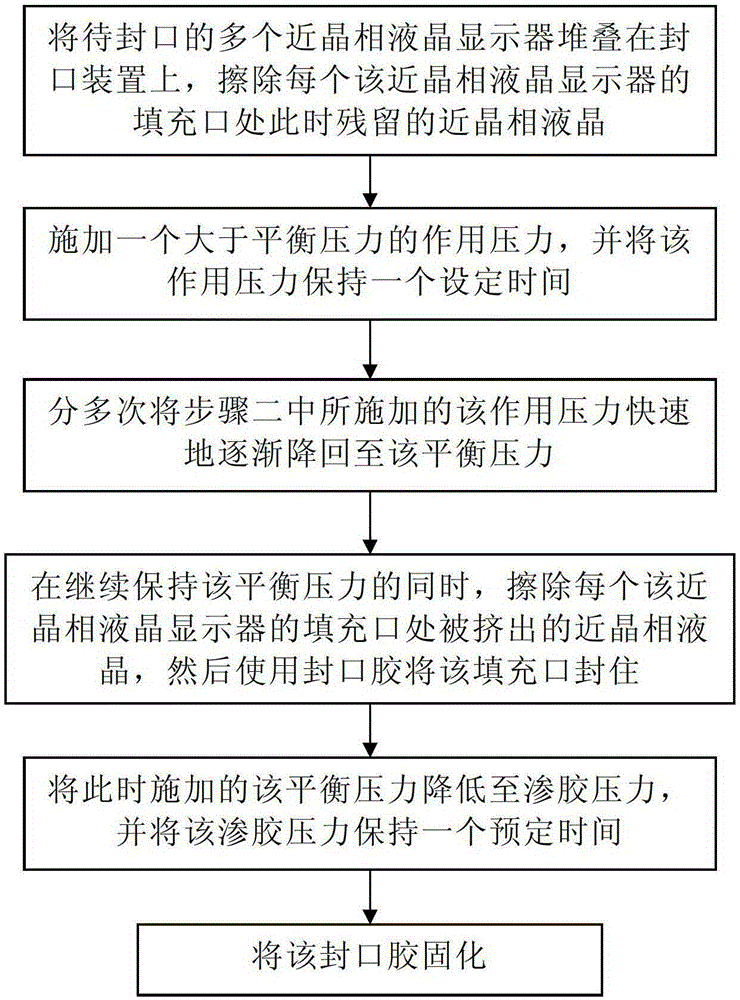

[0035] like figure 1 and figure 2 As shown, the smectic liquid crystal display sealing process of the present invention comprises the following steps:

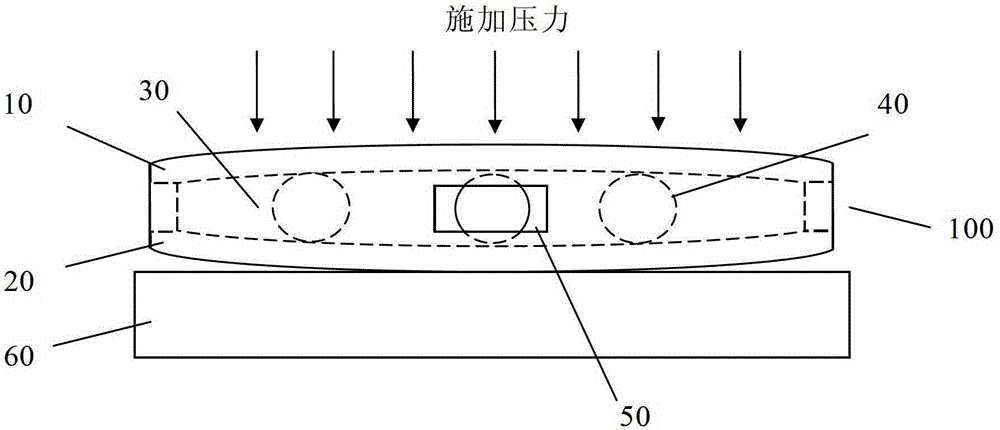

[0036] Step 1: Stack a plurality of smectic liquid crystal displays 100 (1-1000) to be sealed on the sealing device 60, such as figure 2 , the outer surface of one of the substrates 10 or 20 of each smectic liquid crystal display 100 is stacked towards the placement surface of the sealing device 60, and the filling port 50 is towards the side, figure 2 The figure only shows the situation of placing one smectic liquid crystal display, and then erasing the remaining smectic liquid crystal at the filling port 50 of each smectic liquid crystal display 100 at this time.

[0037] Step 2: Along the direction perpendicular to the substrate 10 or 20 of the smectic liquid crystal display 100 (such as figure 2 ) applying an acting pressure greater than the equilibrium pressure, and maintaining the acting pressure for a set time, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com