Inflaming retarding typed carbon fiber heating cable

A carbon fiber heating and flame-retardant technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of unsatisfactory flame-retardant effect, affecting material bending performance, increasing product cost, etc., achieving high electrothermal conversion efficiency, Long service life, the effect of improving the overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Example 1

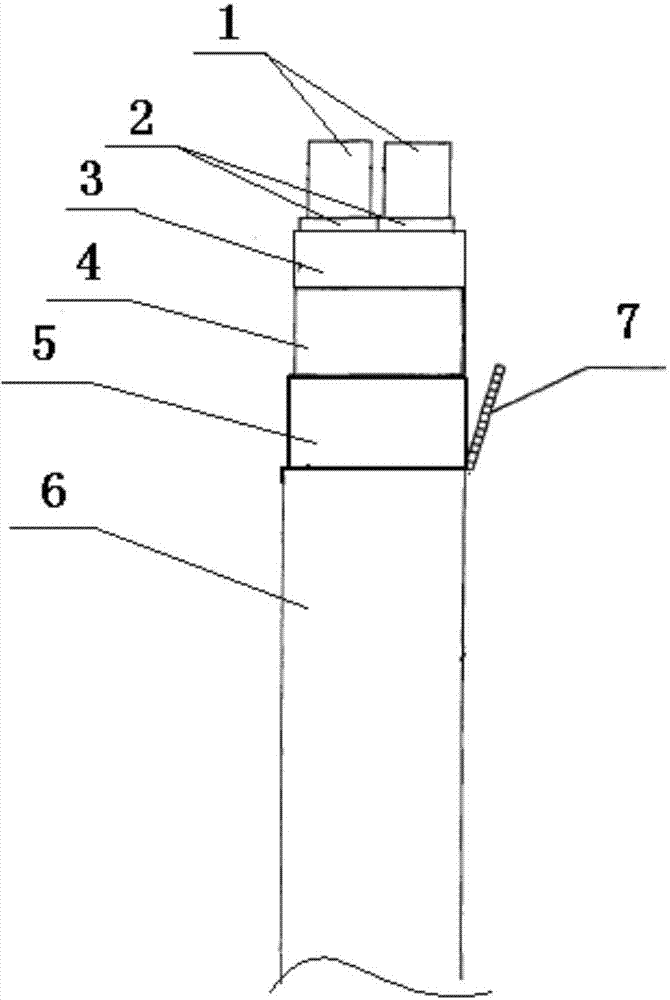

[0023] A flame-retardant carbon fiber heating cable, comprising a heating element 1, the heating element 1 is composed of carbon fiber; the heating element 1 is covered with a protective sleeve 2 made of F46, the protective sleeve 2 is outside an insulating layer, the insulating layer It is composed of an inner insulating layer 3 and an outer insulating layer 4. The outer insulating layer 4 covers the outer periphery of the inner insulating layer 3, the inner insulating layer 3 is made of high-temperature resistant material dimethyl silicone rubber, and the outer insulating layer 4 Made of polyethylene, the outer insulating layer 4 is wrapped with a laminated aluminum foil shielding layer 5, and the shielding layer 5 is wrapped with a threading sleeve 6; a ground wire 7 is installed between the shielding layer 5 and the threading sleeve 6.

Example Embodiment

[0024] Example 2

[0025] Such as figure 1 As shown, a flame-retardant carbon fiber heating cable includes a heating element 1, which is made of carbon fiber; the heating element 1 is covered with a protective sleeve 2 made of F46, and the protective sleeve 2 has an outer insulating layer The insulating layer is composed of an inner insulating layer 3 and an outer insulating layer 4, the outer insulating layer 4 covers the outer circumference of the inner insulating layer 3, the inner insulating layer 3 is made of high-temperature resistant material polyvinyl chloride plastic, The outer insulating layer 4 is made of polyethylene, the outer insulating layer 4 is wrapped with a laminated copper foil shielding layer 5, and the shielding layer 5 is wrapped with a threading sleeve 6; a ground wire 7 is installed between the shielding layer 5 and the threading sleeve 6.

Example Embodiment

[0026] Example 3

[0027] Such as figure 1 As shown, a flame-retardant carbon fiber heating cable includes a heating element 1. There are two heating elements 1, both of which are made of carbon fiber; the heating element 1 is covered with a protective sleeve 2 made of F46. 2 Peripheral insulation layer, the insulation layer is composed of the inner insulation layer 3 and the outer insulation layer 4, the outer insulation layer 4 covers the outer circumference of the inner insulation layer 3, the inner insulation layer 3 is made of high temperature resistant material methyl Made of fluorosilicone rubber, the outer insulating layer 4 is made of polyethylene; the outer insulating layer 4 is wrapped with a shielding layer 5 made of braided copper mesh, and the shielding layer 5 is wrapped with a threading sleeve 6; the shielding layer 5 and the threading sleeve A ground wire 7 is installed between 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com