Exhaust gas recirculation modules for internal combustion engines

A technology of exhaust gas recirculation and exhaust gas recirculation valve, which is applied in the direction of exhaust gas recirculation, internal combustion piston engine, combustion engine, etc., can solve the problems of high structural space requirements and installation costs, and save parts, avoid pipelines, and structural space high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

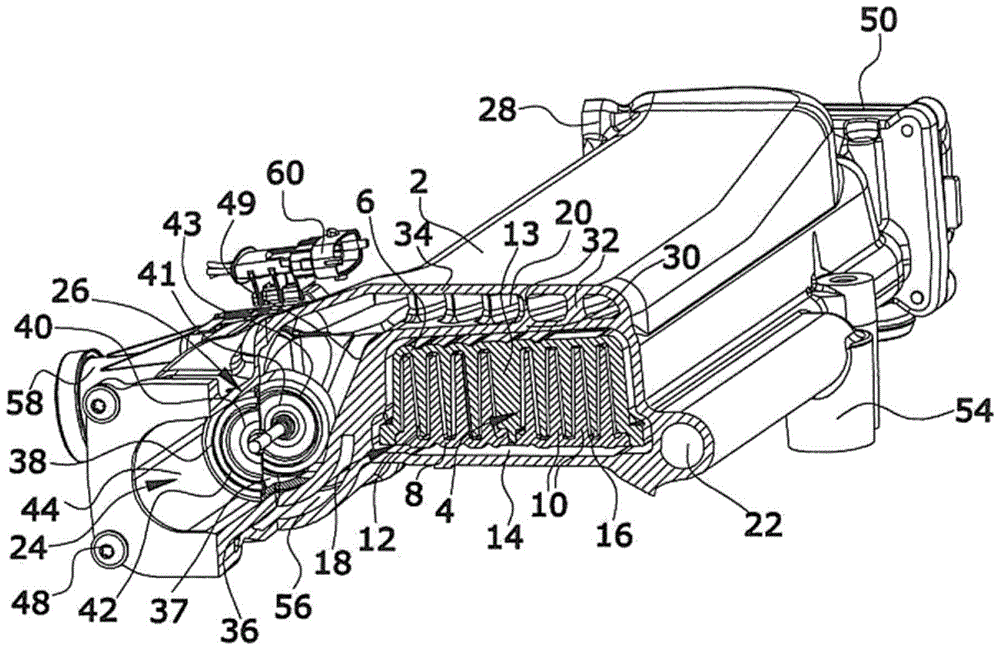

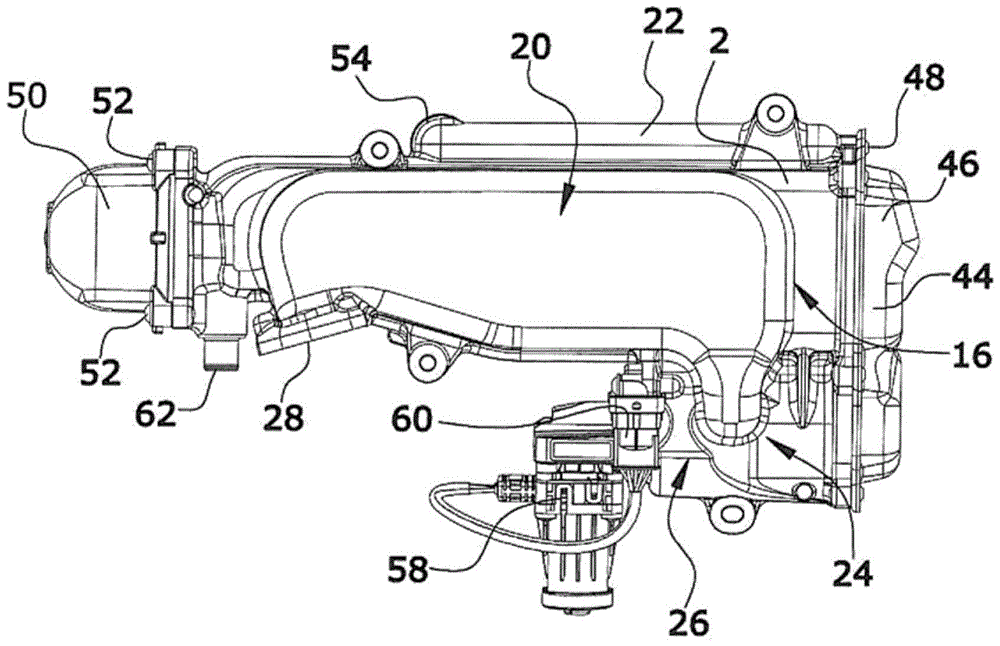

[0019] The exhaust gas recirculation module according to the invention comprises two housings which are nested in one another, wherein the housing which is manufactured in a sand casting process, preferably in one piece, is the housing 2 , inside which housing 2 is located, preferably in a die casting process. Manufactured inner shell4. The inner housing 4 is produced in two pieces and has a pot-shaped first housing part 6 and a second housing part in the form of a cover 8 closing it in cross-section, for example by contacting connected by friction welding. Ribs 10 extend from the cover 8 and from the first housing part 6 into an exhaust gas channel 12 formed inside the inner shell 4 , which in the present embodiment is divided into two channels separated by a longitudinal wall 13 . The ribs 10 are arranged at a relatively small distance from each other.

[0020] The inner shell 4 is surrounded by coolant channels, which are formed as a coolant jacket 14 and are formed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com