Sensor component housing

一种传感器、构件的技术,应用在传感器构件壳体领域,能够解决传感器难接近、昂贵、损失等问题,达到避免不密封的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

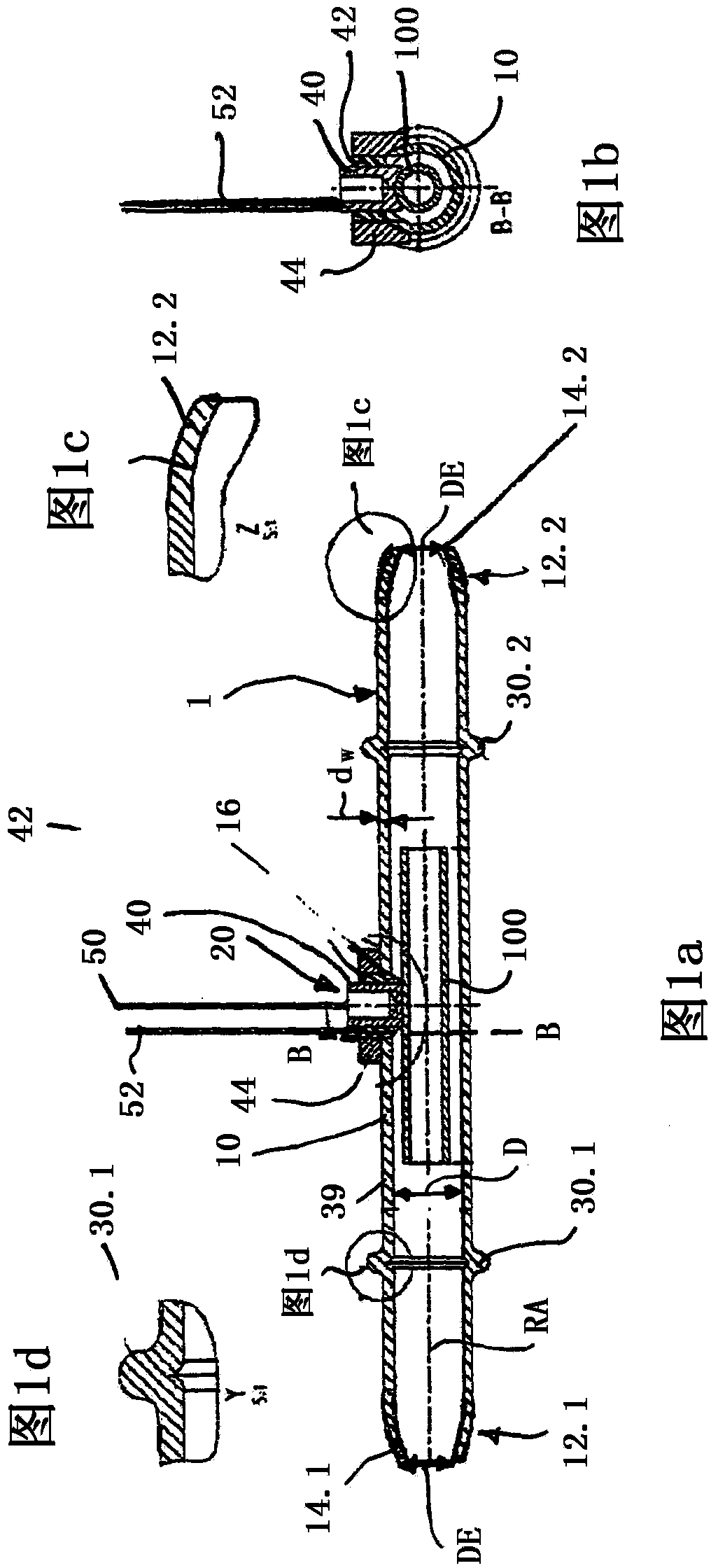

[0042] exist Figures 1a to 1d shows a device for receiving and / or conducting a liquid or gaseous medium with a sensor component 100 which is inserted into a sensor component housing 10 according to the invention. Figure 1a A longitudinal section through a device 1 of this type is shown. The sensor component housing 10 has a circular cross-section, which in Figure 1b is shown in the plane B-B.

[0043] The circular tube cross-section has a diameter D. According to the invention it is provided that the sensor component housing 10 has a bead 14.1 or 14.2 in the region of the first end 12.1 and the second end 12.2. Flange 12.2 in Figure 1c shown in detail. During flanging, the first end 12.1 or the second end 12.2 of the tube section of the sensor component housing 10 is upset, for example with a forming tool, the diameter is reduced from the diameter D in the region of the tube center to the tube end. Diameter DE at section (12.1, 12.2). Although the diameter DE at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com