Novel vacuum suction plate structure

A vacuum suction plate and vacuum suction cup technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of economic loss, application obstruction, unstable performance, etc., and achieve the effects of preventing unsealing, enhancing strength, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

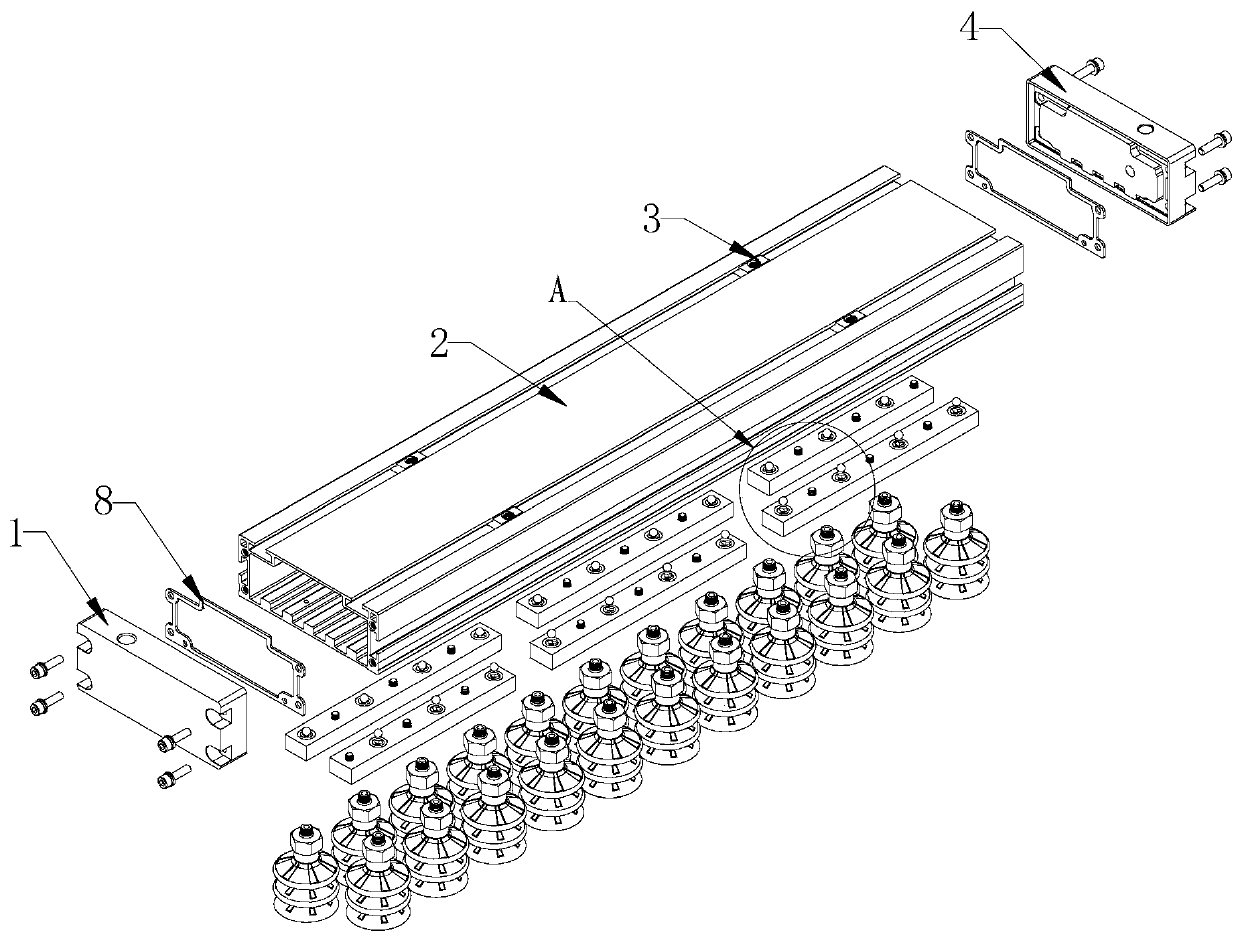

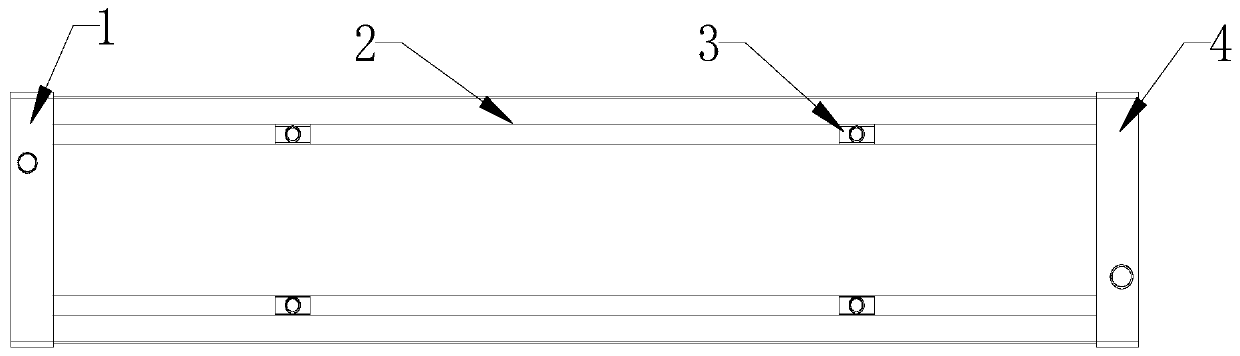

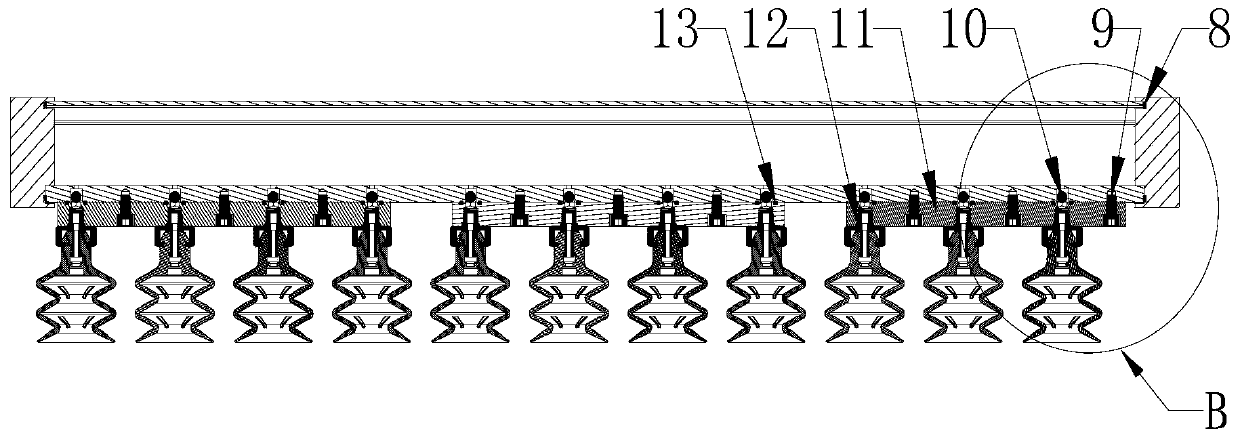

[0043] Please refer to Figure 1-7 Shown, embodiment one of the present invention is:

[0044] A novel vacuum suction plate structure of the present invention includes a suction plate and a suction cup assembly;

[0045] The suction plate includes a left side cover 1, a suction plate main body 2, a nut block 3, a right side cover 4, a side cover gasket 8, a screw 9, a stainless steel bead 10, a suction cup bead 11 and a sealing ring 13; the suction plate main body 2 is a shell with openings at opposite ends and a hollow interior, the shell is in the shape of a strip-shaped cuboid, and is integrally formed of metal material. The left side cover 1 and the right side cover 4 are respectively arranged at the openings at both ends of the suction plate main body 2, the side of the left side cover 1 close to the suction plate main body and the right side cover 4 close to the suction plate main body are both A groove matching the end of the main body of the suction plate is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com