Transmission for a motor vehicle

A technology for transmissions and motor vehicles, which is applied in the direction of vehicle gearboxes, transmissions, mechanical equipment, etc. It can solve the problem that the switching element clutch is difficult to access, etc., and achieve good accessibility, low structural complexity, low transmission cost and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

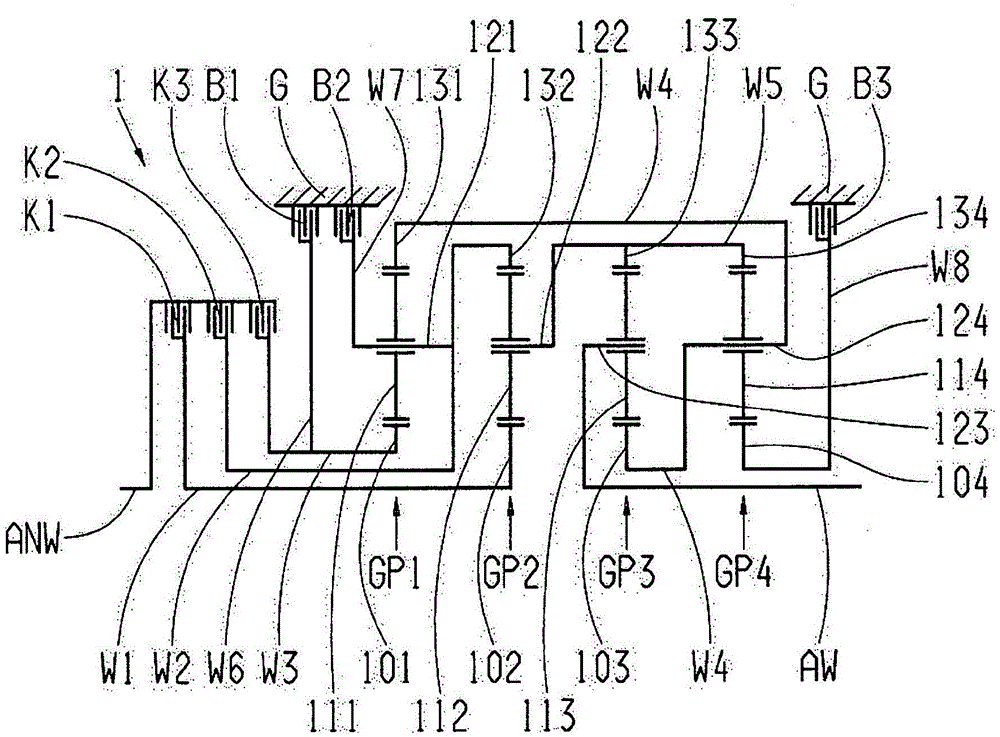

[0047] figure 1 A transmission according to a first embodiment of the invention is shown.

[0048] exist figure 1 In , reference numeral 1 denotes a multi-stage transmission. The multi-stage transmission 1 includes six shift elements in the form of three clutches K1 , K2 , K3 and three brakes B1 , B2 , B3 . The drive side of the transmission can be coupled or connected to the output side by means of the clutches K1 , K2 , K3 for the transmission of forces and torques. To this end, the first clutch K1 , the second clutch K2 and the third clutch K3 are connected to the drive shaft ANW on the drive side. The first clutch K1 is also connected with the first shaft W1 such that the clutch, when operated, transmits force and torque from the drive shaft ANW to the first shaft W1. The same applies to the second clutch K2 and the third clutch K3. When the second clutch K2 is engaged, force is transmitted from the drive shaft ANW to the second shaft W2, and when the third clutch K3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com