A kind of shoe upper and its manufacturing process

A technology for manufacturing crafts and uppers, which is applied in the direction of shoe uppers, footwear, and shoe-making machinery. It can solve the problems of uncoordinated shoe lightness, upper support, and aesthetics, and achieve obvious three-dimensional effects and exquisite and beautiful patterns. , Strong upper support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

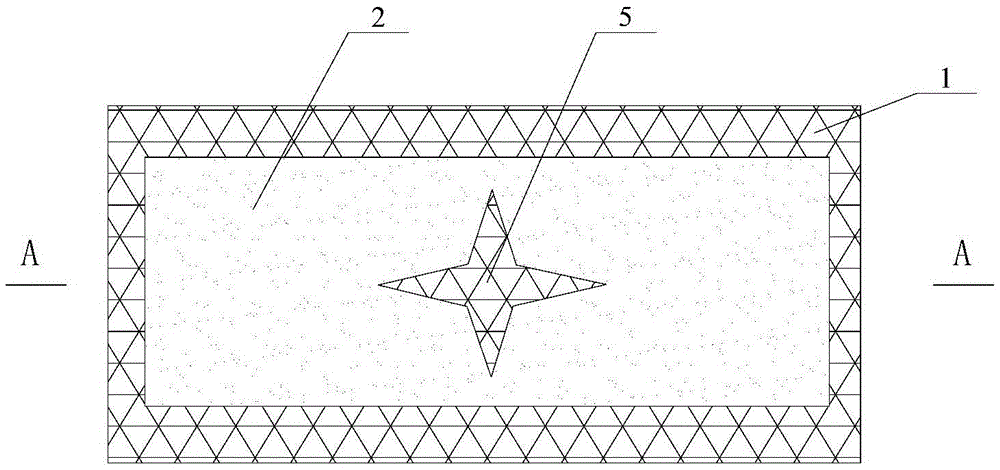

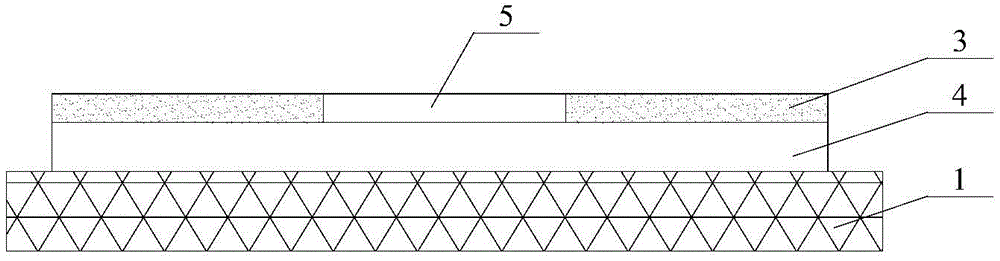

[0021] Such as Figure 1 to Figure 2 Shown, the present invention provides a kind of novel vamp manufacturing process, comprises the following steps:

[0022] According to the different styles and types of shoes, choose the high and low temperature film with suitable specifications;

[0023] According to the selected high and low temperature film specifications, the thickness value of the texture layer in the high and low temperature film is obtained;

[0024] Adjust the working parameters of the laser engraving machine to the texture layer thickness of the hollowed-out pattern part and the outer contour size of the required pattern part;

[0025] Laser engraving machine for cutting and processing;

[0026] The processed high and low temperature film is hot-pressed on the surface of the shoe upper through a non-sewing process.

[0027] The present invention also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com