Special gluing machine for manufacturing honeycomb paper ball

A technology of glue coating machine and paper ball, applied in the field of glue coating machine, can solve the problems of low production efficiency, unsatisfactory product quality and effect of paper ball lanterns, glue condensation and blockage, etc., and achieve the effect of saving glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

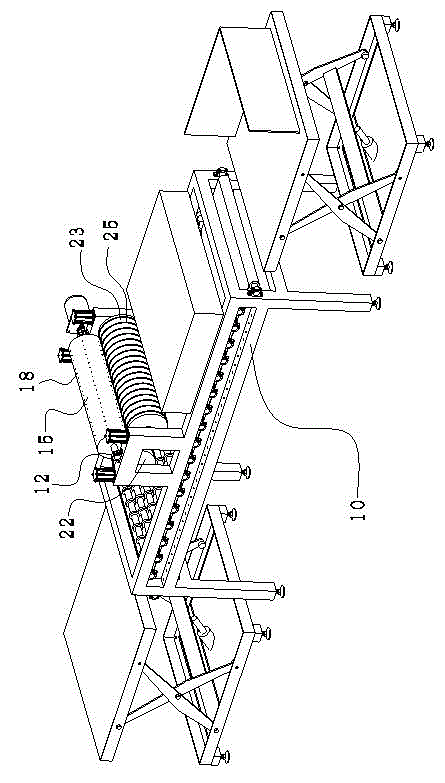

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

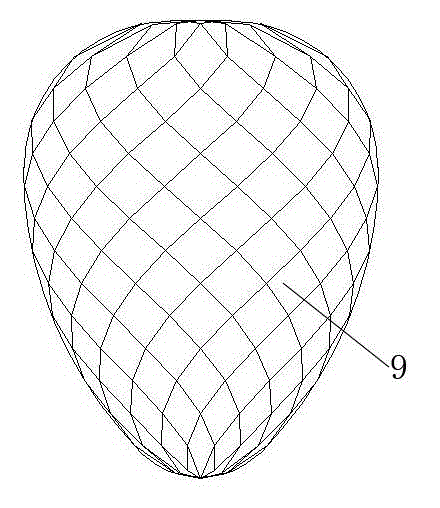

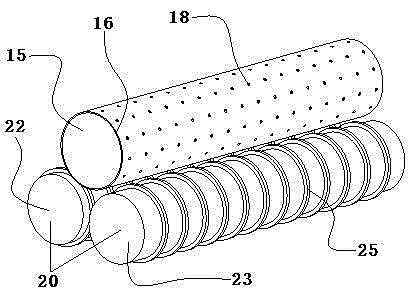

[0019] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a special gluing machine for making honeycomb paper balls according to the present invention is used for making figure 1 The shown honeycomb paper ball 9 is used for gluing, and the gluing machine includes a machine base 10, a roll frame 12 fixedly installed on the base 10, a rubber storage roller 15 installed on the roll frame 12, The front glue roller 22 and the rear glue roller 23 are two glue rollers 20 installed on the roller frame 12, and the glue storage roller 15 is covered with a glue seepage layer 16, and the glue roller 20 is arranged along the axial direction. A plurality of resilient glue-coating rings 25 are equidistantly arranged, and the positions of the glue-coating rings 25 of the front glue-coating roller 22 and the rear glue-coating roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com