A production process of rolling products

A production process and product technology, which is applied in the production process field of rolling products, can solve the problems of complex processing process and high material consumption, and achieve the effects of smooth production process, high production efficiency and low defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

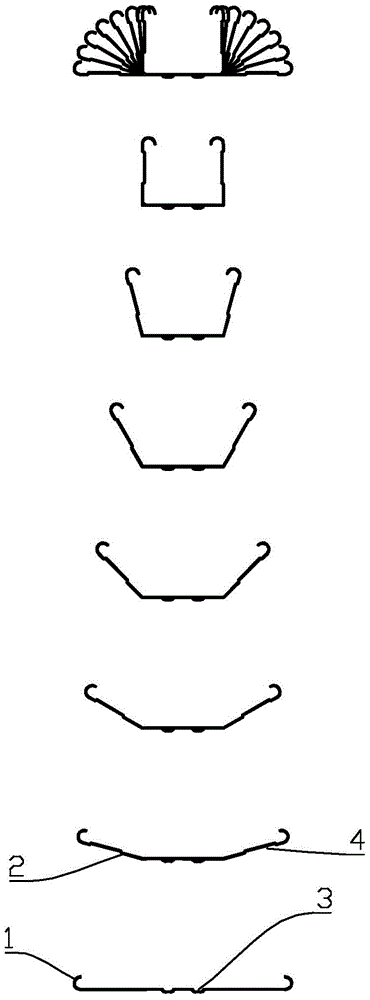

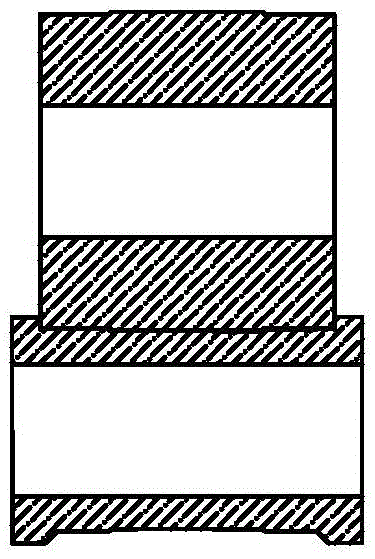

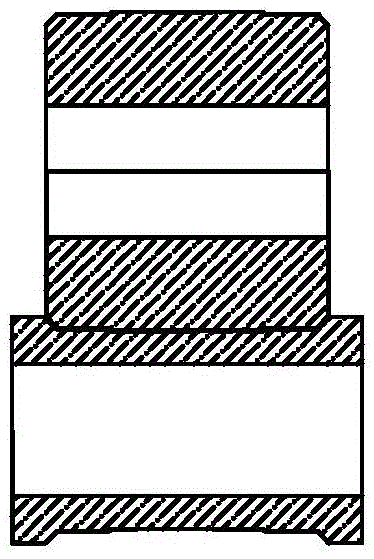

[0025] refer to Figure 1 to Figure 13 , the present invention is a kind of production technology of rolling product, comprises the following steps: 1, prepare raw material: metal plate, can adopt other metal plates such as stainless steel plate or alloy plate; Punching at the set position of the sheet (for assembly); 3. Roll out the first groove 3 in the middle of the sheet metal by the rolling machine to strengthen the structural strength of the sheet metal; 4. Roll the sheet metal by the rolling machine Folding treatment is carried out on both sides, forming a folded edge 1 at 90° to the main body of the sheet metal on both sides; 5. Folding the edge 1 by a rolling press; 6. Folding the metal sheet by a rolling press, two The side forms a side 2 that is 90° to the main body of the sheet metal, and forms a second groove 4 on the side 2 at the same time, which is used to strengthen the structural strength of the side 2; Correct the verticality between them, and correct the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com