A wear-resistant lubricating punch structure for a powder metallurgy mold

A powder metallurgy, anti-wear technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of increasing equipment maintenance and replacement costs, and achieve the effects of preventing cold welding, reducing demoulding force, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

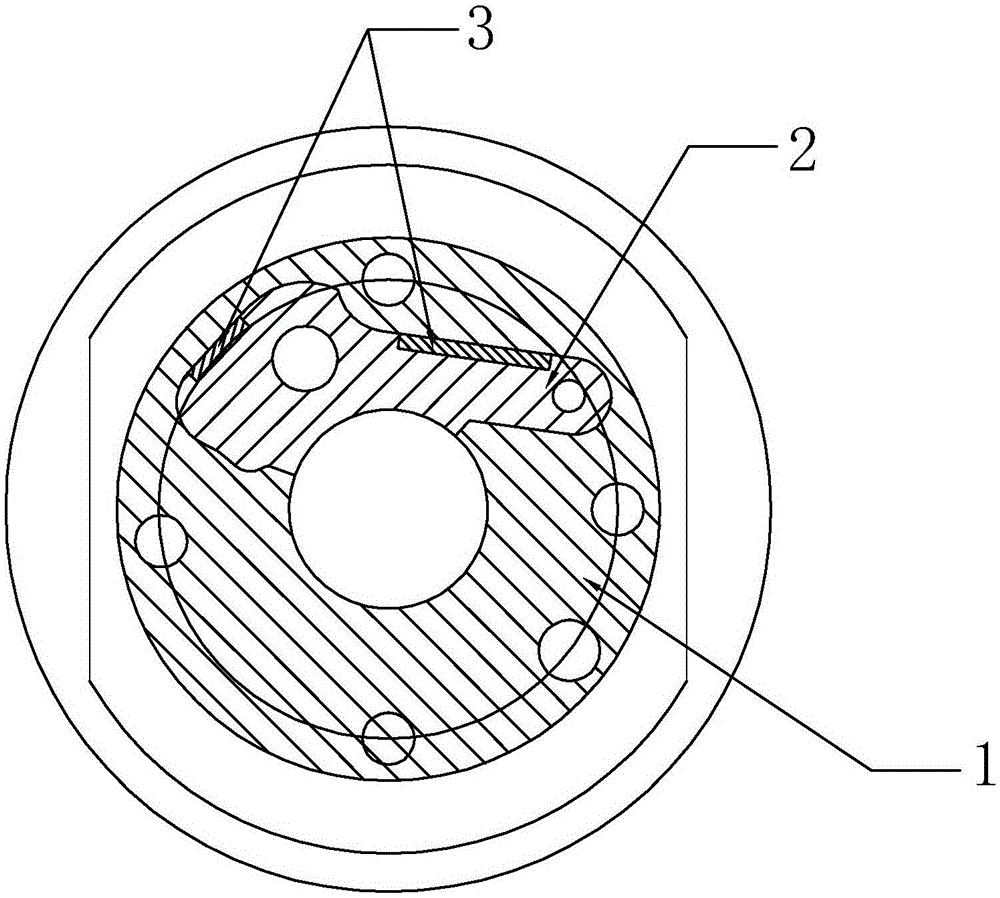

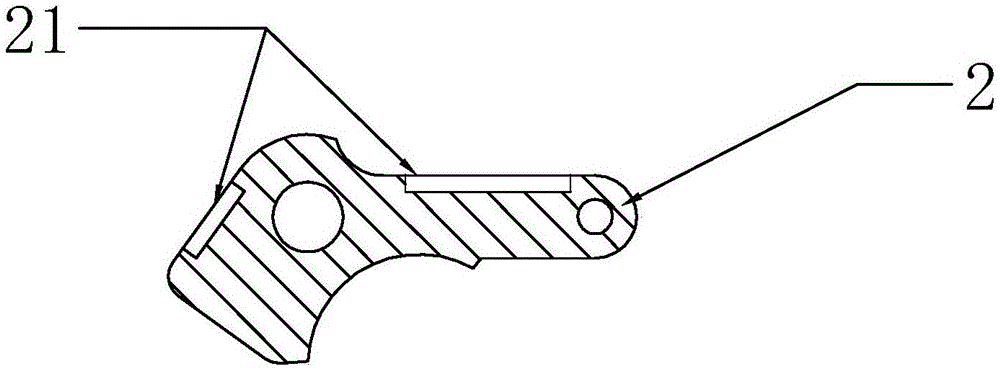

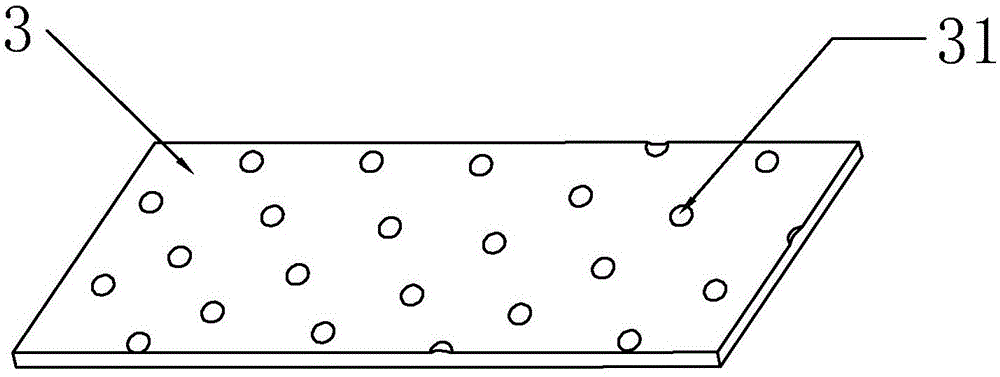

[0017] refer to Figure 1 to Figure 3 , an anti-wear lubricating punch structure of a powder metallurgy mold according to the present invention, comprising a first die punch 1, and a second die punch 2 fitted in the first die punch 1, the second die punch 2 The side is provided with a fixing groove 21, and a sheet-shaped lubricating bearing 3 is clamped in the fixing groove 21. The outer surface of the lubricating bearing 3 protrudes from the side of the second die punch 2 and is offset against the inner surface of the first die punch 1. Next, the outer surface of the lubricating bearing 3 is provided with a notch 31 for accommodating lubricating liquid such as butter. The outer surface of the lubricating bearing 3 is a working surface, which is slidingly matched with the inner surface of the first die punch 1 .

[0018] A plurality of notches 31 are provided on the outer surface of the lubricating bearing 3 .

[0019] The notches 31 are linearly and equidistantly arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com