Beam and longitudinal beam connecting assembly

A technology for connecting components and connectors, which is applied in vehicle parts, substructure, transportation and packaging, etc., and can solve problems such as wrinkling of sheet metal at the transition of rounded corners, cracking of parts, and difficulty in forming structures at U-shaped laps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

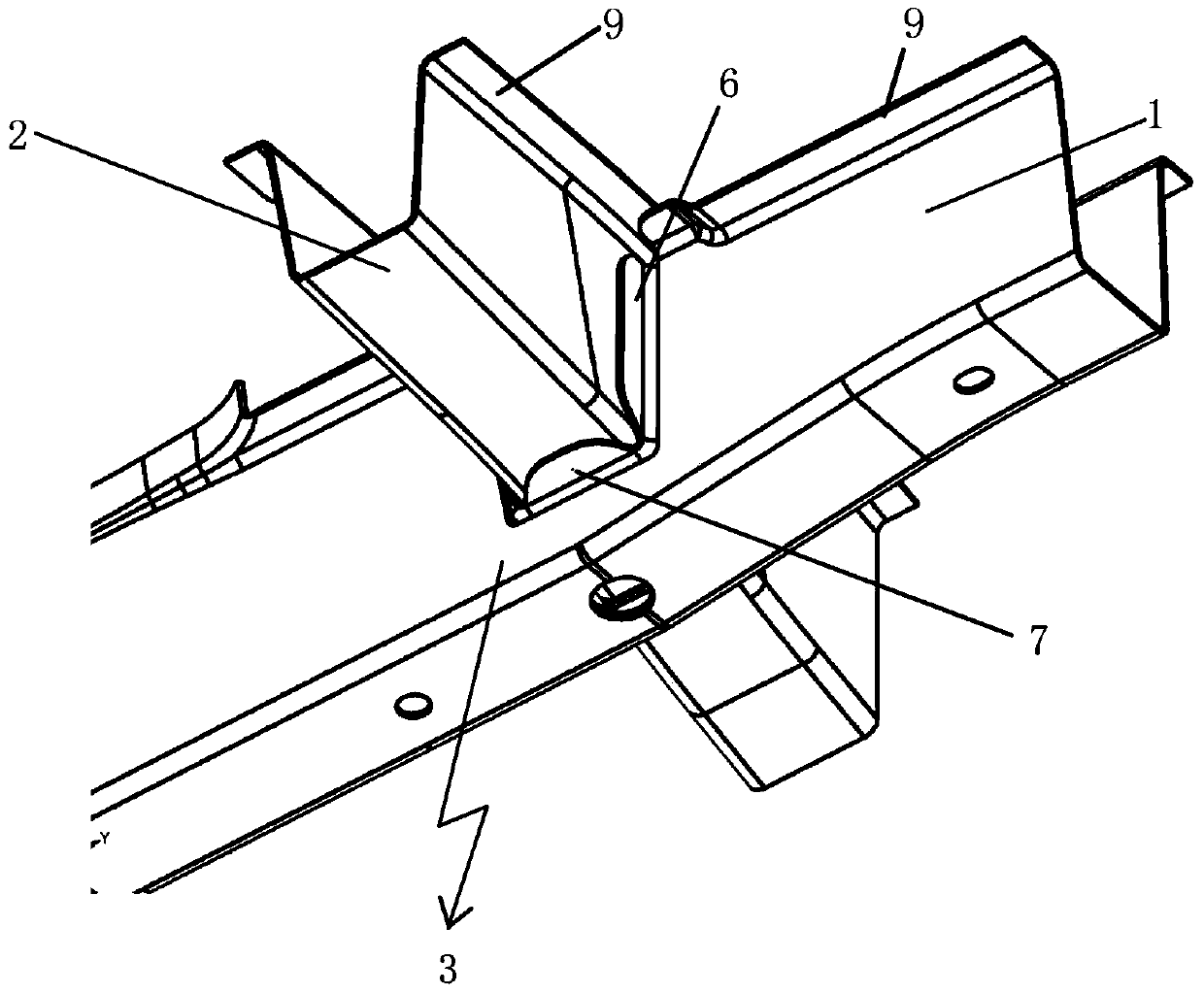

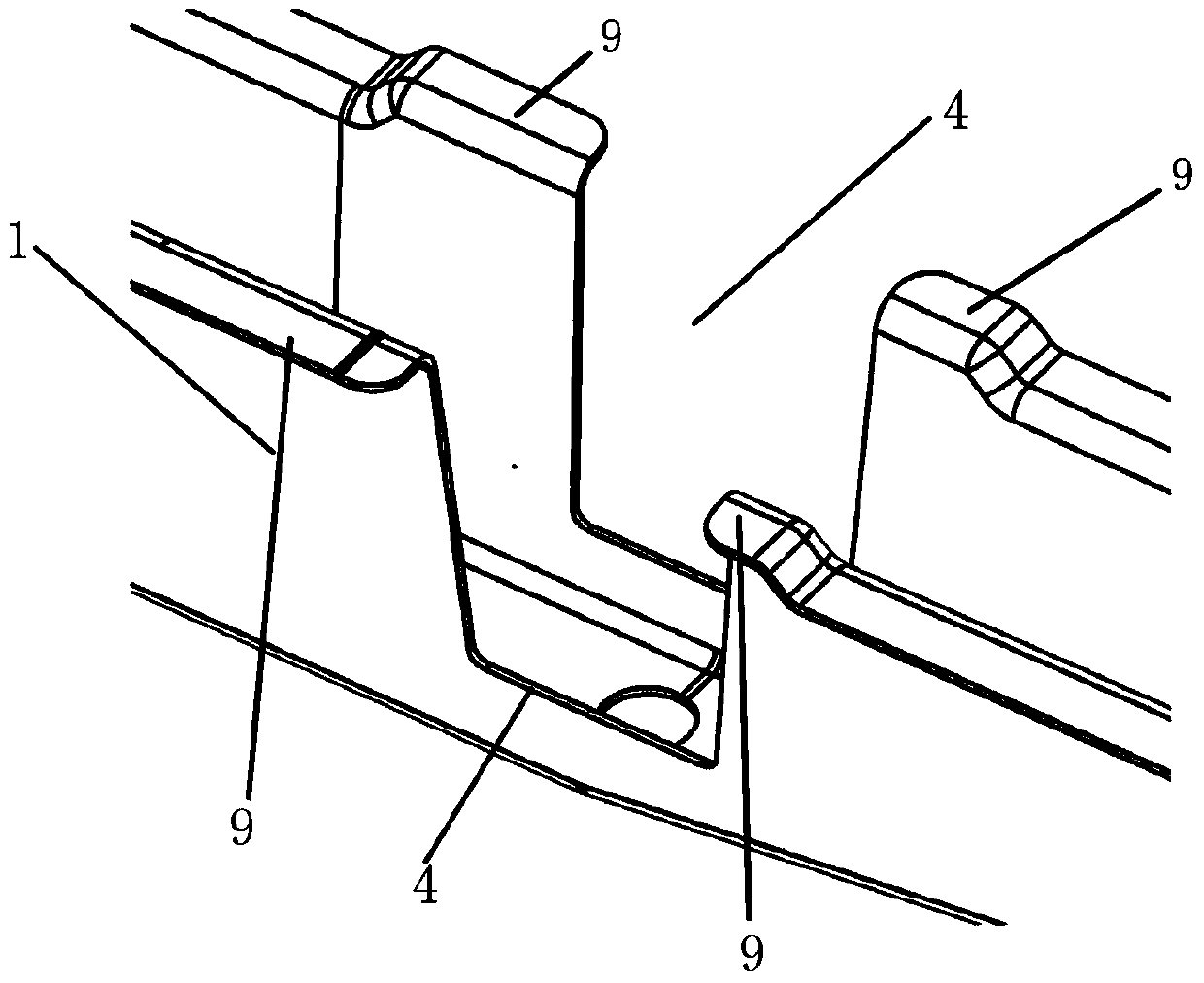

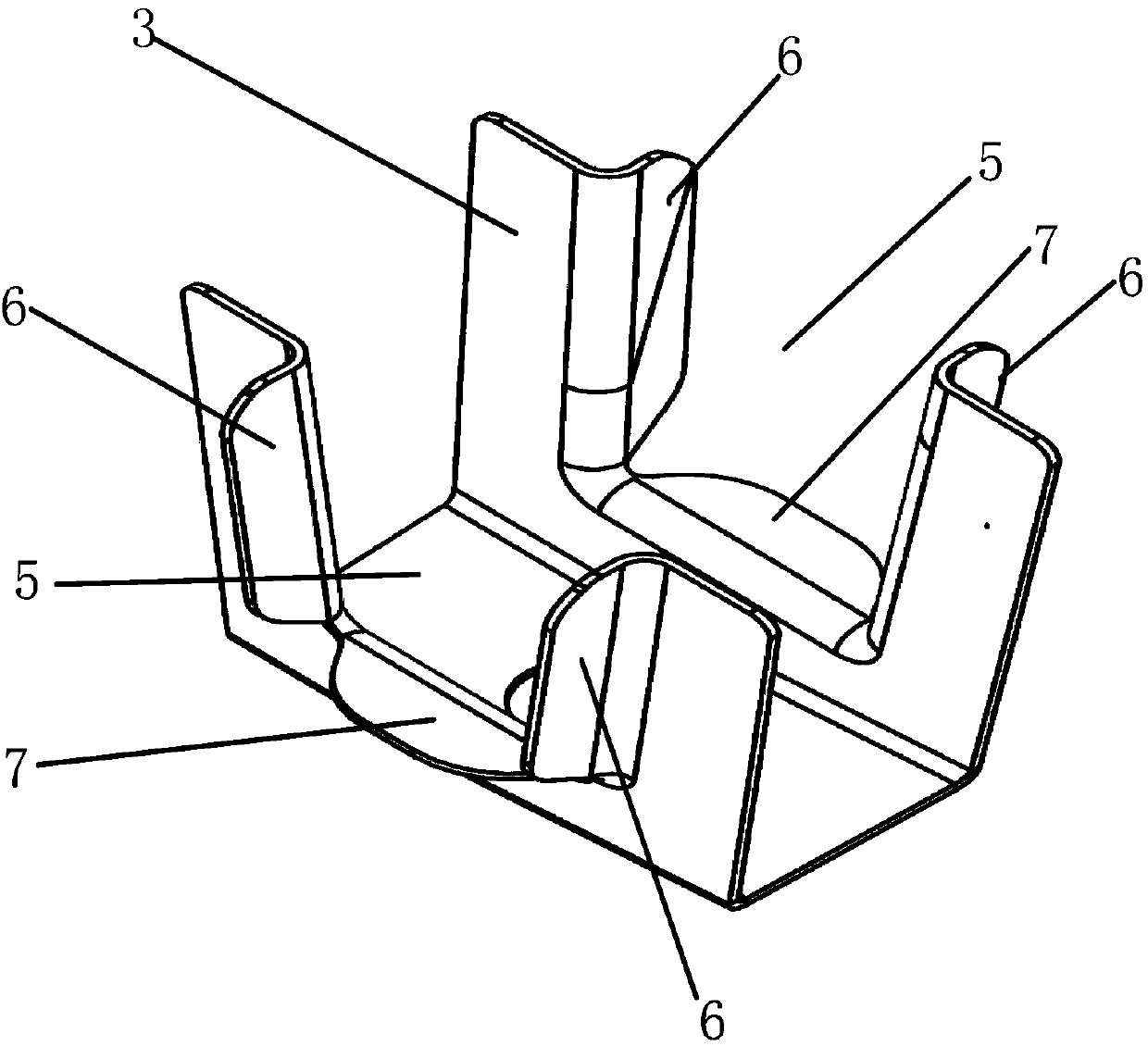

[0025] The following with attached Figure 1 to Figure 6 A transverse and longitudinal beam connection assembly of the present invention will be further described in detail.

[0026] A transverse and longitudinal beam connection assembly of the present invention, please refer to Figure 1 to Figure 6 , including a crossbeam 1 and a longitudinal beam 2 and a connecting piece 3 for connecting the crossbeam 1 and the longitudinal beam 2, the connecting piece 3 is provided with a docking opening 4 at the corresponding position of the crossbeam 1 relative to the two arms, and the connecting piece 3 It is a hollow block, and the middle part of the two side walls of the connecting piece 3 is provided with a connecting opening 5, and the butt joint opening 4 on the beam 1 corresponds to the position, shape and size of the connecting opening 5 of the connecting piece 3, so The side wall of the connector 3 is provided with an outwardly turned wall 6 at the connection opening 5, the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com