Ram-type composite pedrail wheel

A stamping and crawler technology, which is applied in the field of stamping composite track wheels, can solve the problems of high manufacturing cost and use cost, poor reliability, troublesome processing and installation, etc., and achieve high production efficiency, improved adhesion, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

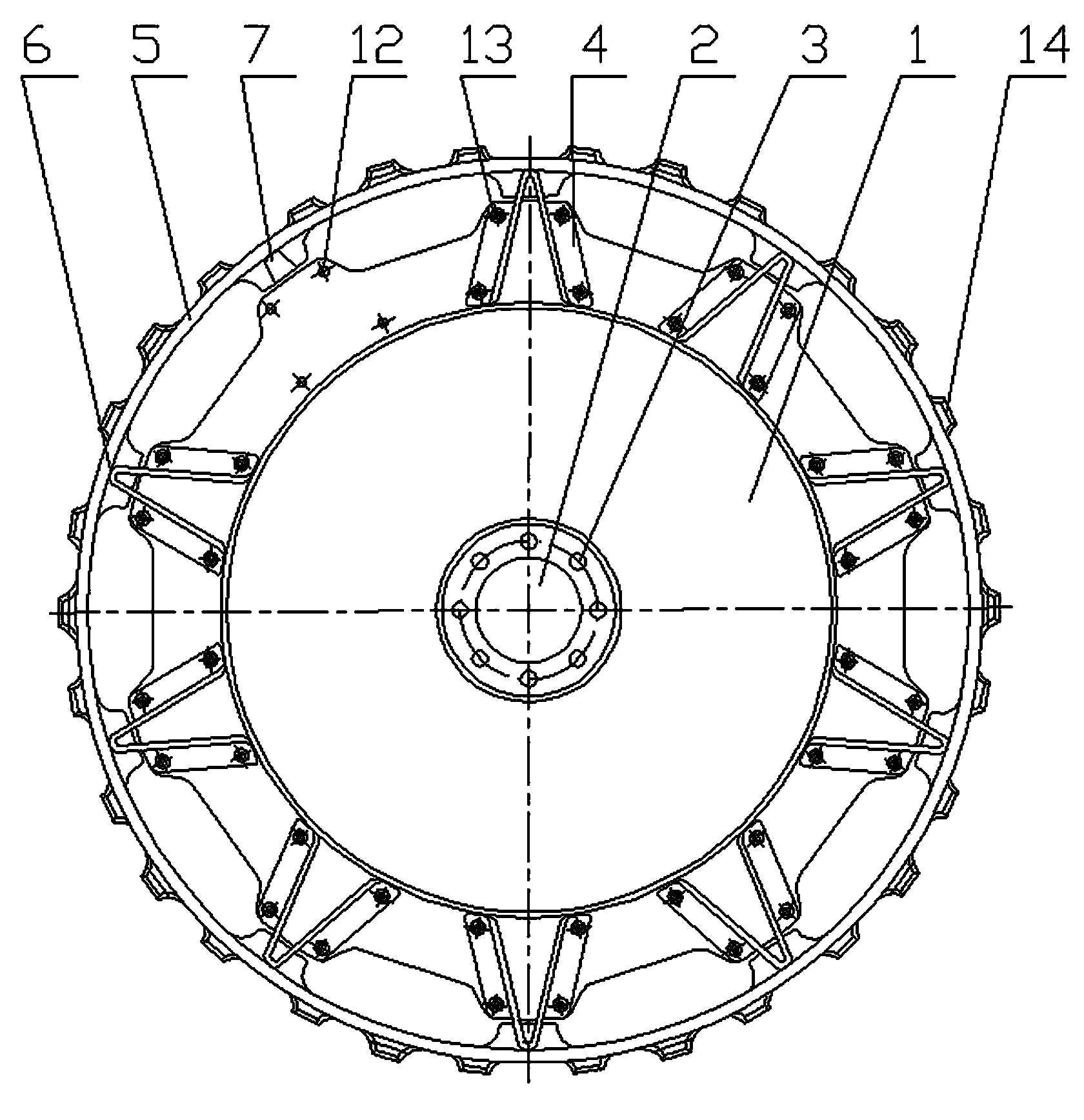

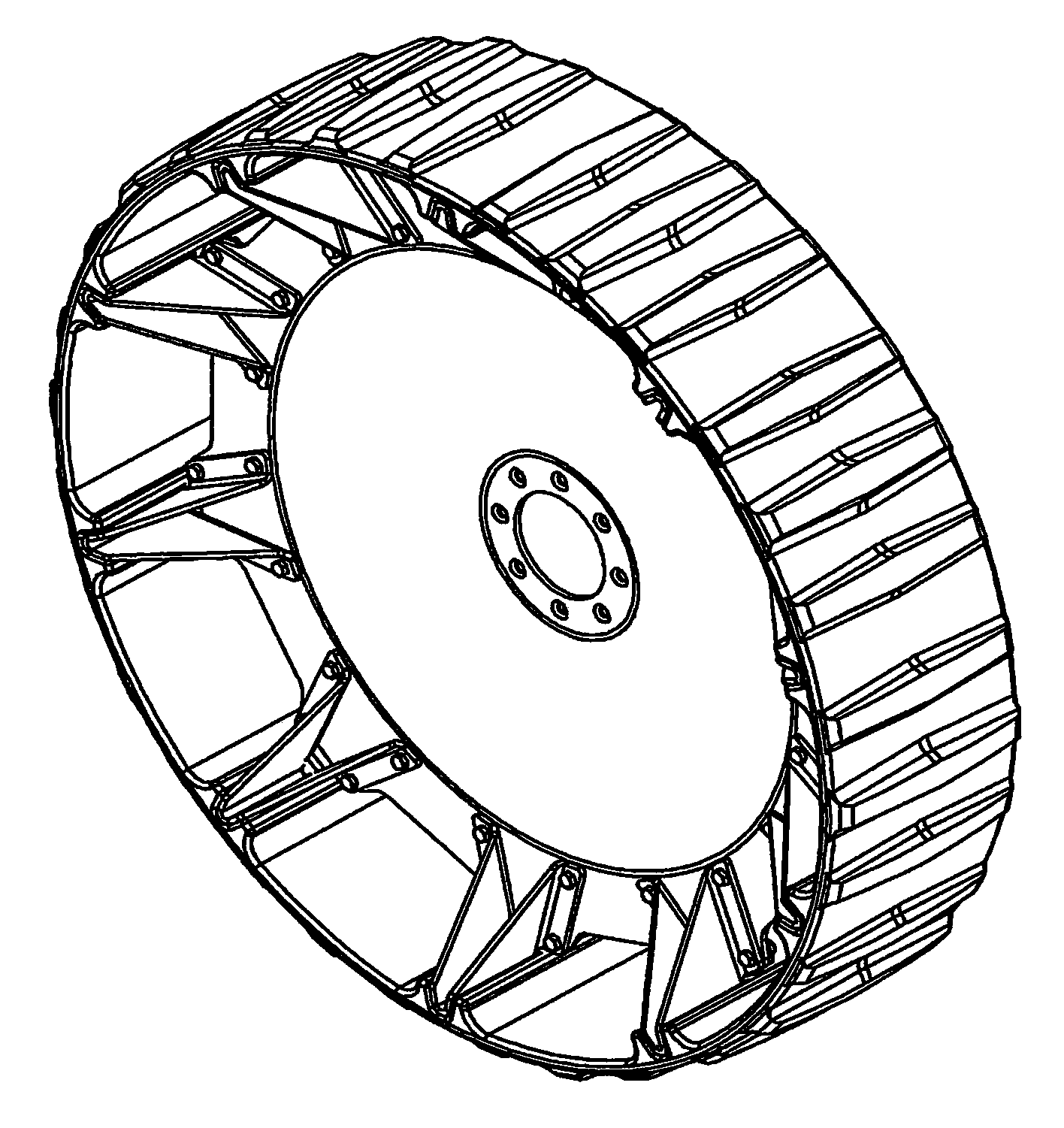

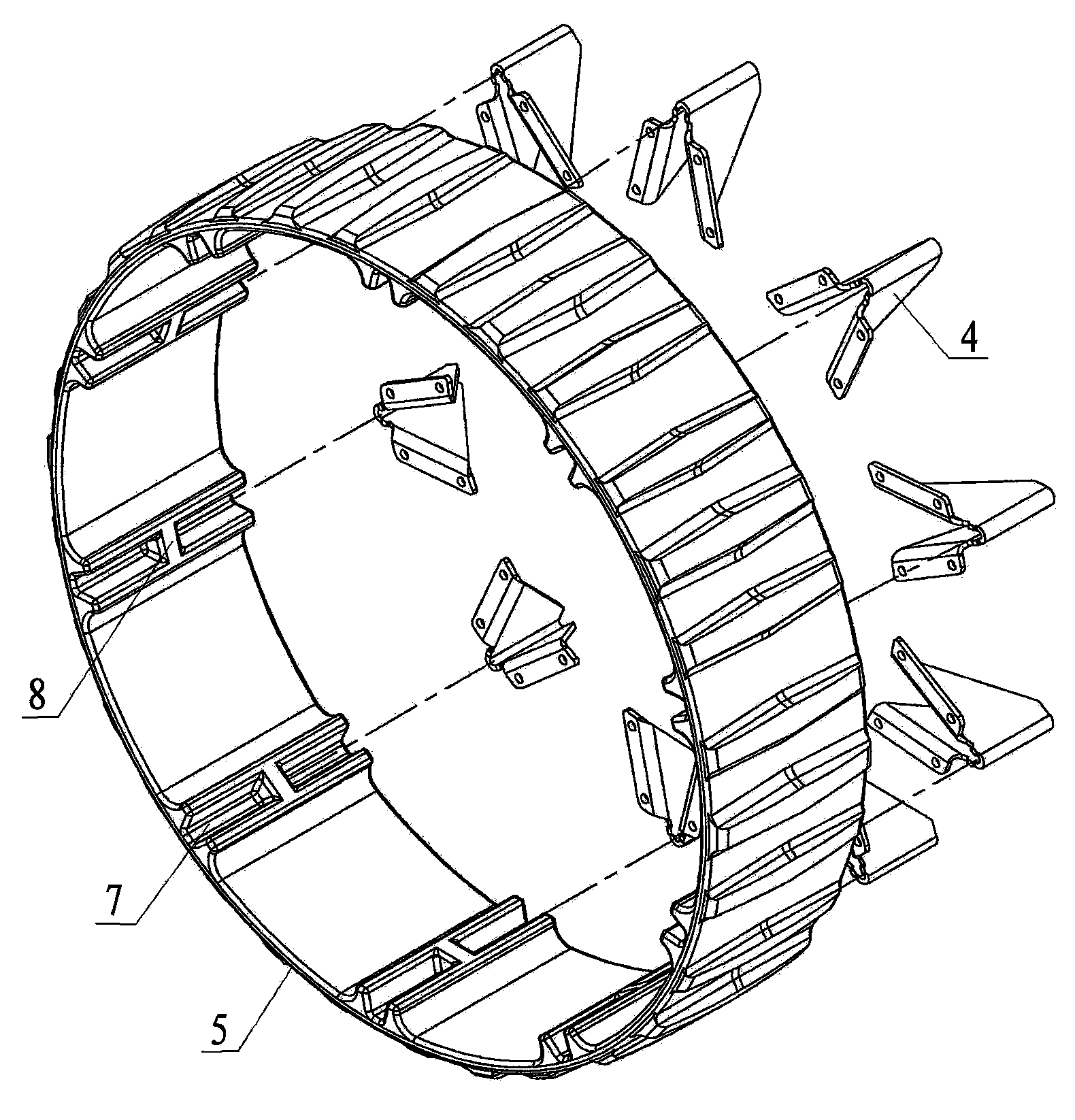

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Figure 1 to Figure 6 It is a structural schematic diagram of a stamped composite crawler wheel. It can be seen from the figure that it includes a disc-shaped spoke 1 stamped from a steel plate such as Figure 7 , Figure 8 As shown, the center of the spoke 1 is formed with a positioning hole 2 and a connecting hole 3 for connecting with the drive shaft, and 10 (total 20) Vs perpendicular to the end surface of the spoke 1 are fixed evenly around the two ends of the spoke 1. Shaped connector 4 such as Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the V-shaped bottom of the connecting frame 4 exposes the outer edge of the spoke 1 to form a positioning gear, and the positioning gear is a circumscribed circle centered on the positioning hole 2, and the positioning gear is wrapped with a ring-shaped rubber track 5. The inne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap