Small flexible wing drone launcher

A flexible wing and small technology, applied in the direction of launch/drag transmission, etc., can solve the problems of short service life of the launch tube, high roughness requirements, high production cost of the launch tube, etc., and achieve the effect of reducing production cost and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

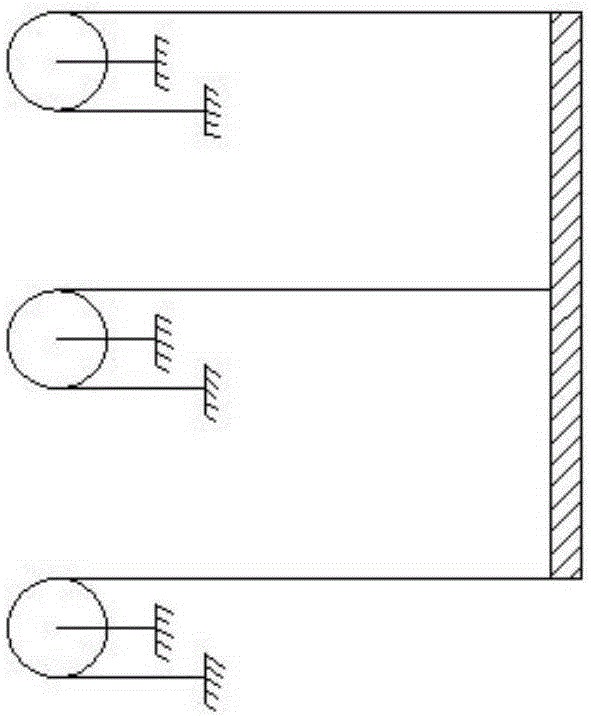

[0023] According to 1, 2, such as figure 1 As shown, one end of the elastic element (5) is fixed in the limiting circular tube (9), and the other end goes around the pulley and is fixed on the push plate (7). symmetrical arrangement;

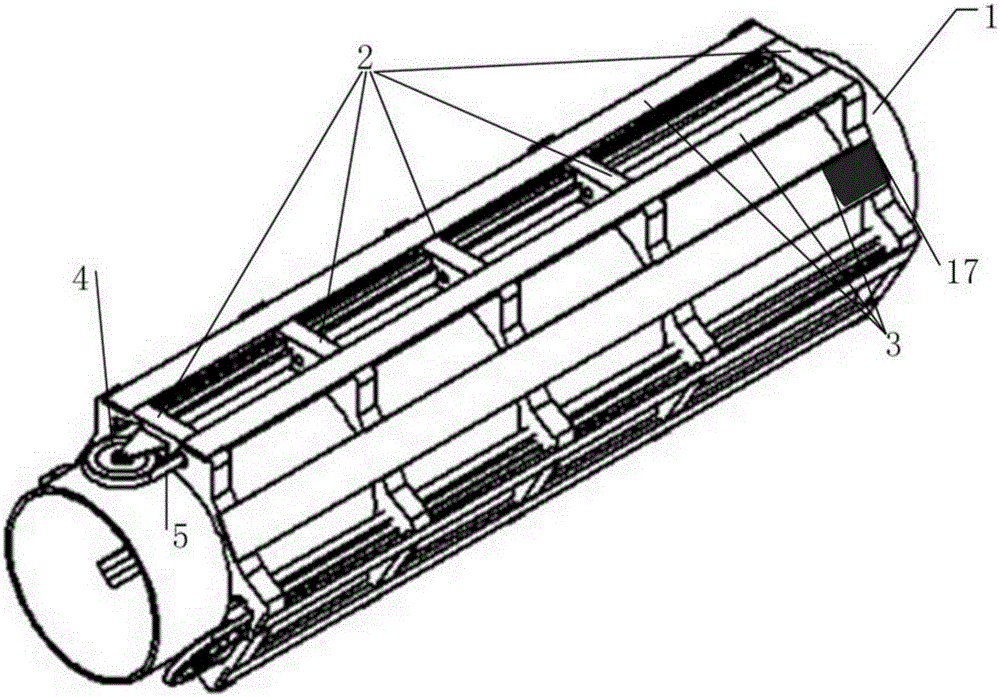

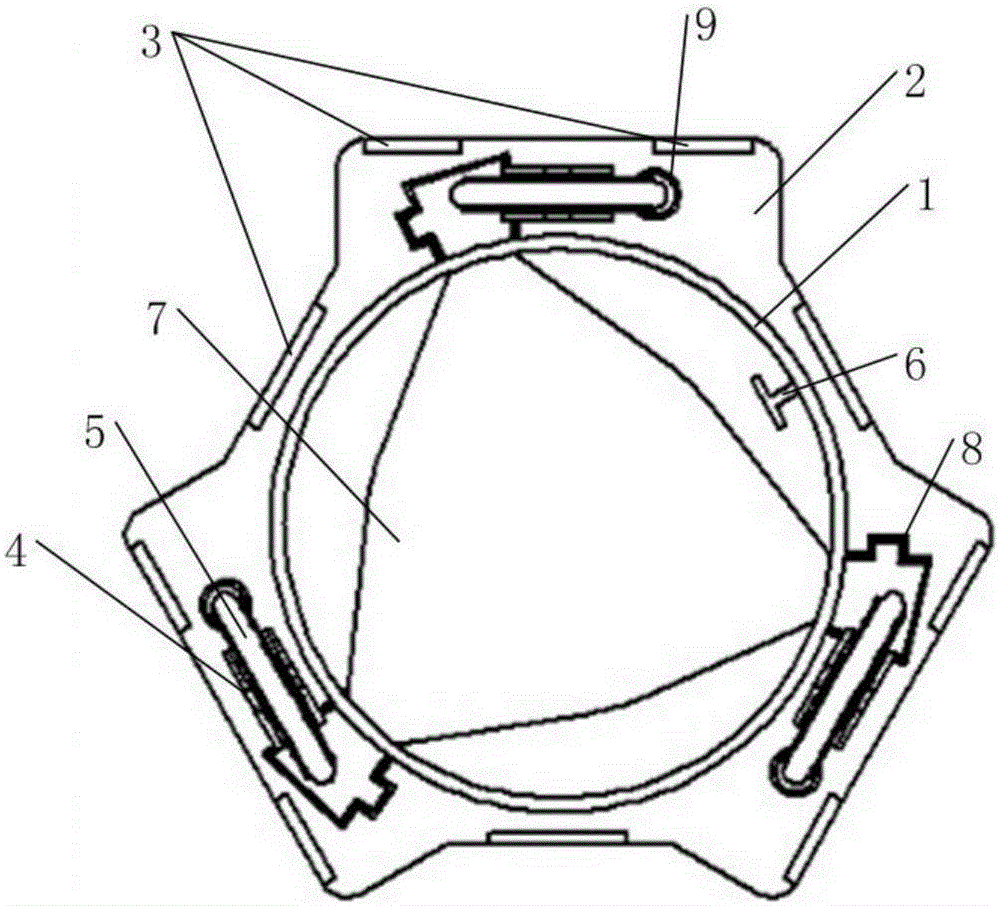

[0024] According to 1, 2, such as figure 2 , image 3 , Figure 4 As shown, the mouth of the launching tube faces the lower left of the paper, the total length of the launching tube (1) is 105 cm, the part in front of the first bulkhead (2) is 10 cm long, and the part behind the last bulkhead (2) is 5 cm long cm, the distance between the middle spacer frames (2) is 20 cm, 20 cm, 20 cm, and 30 cm from the mouth to the end of the tube, respectively; Figure 5 shown.

[0025] The launching tube (1) is sequentially connected with the bulkheads (2), and the bulkheads are sequentially connected by two kinds of stringers (3), the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com