Boiler exhaust gas and wastewater treatment technology

A technology for treating process and boiler waste gas, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Large quantity and other problems, to achieve the effect of small maintenance, long service life and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

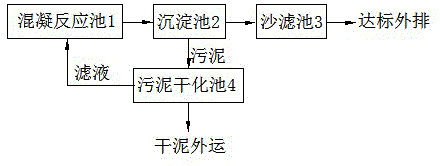

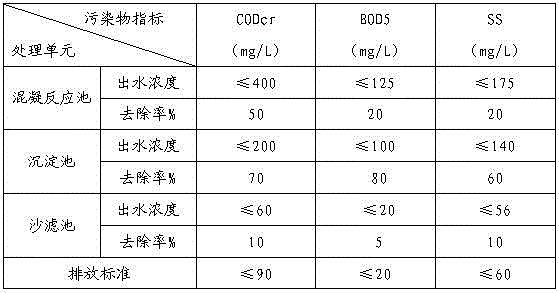

[0018] A treatment process for boiler waste gas and wastewater includes the following steps:

[0019] (1) The wastewater enters the coagulation reaction tank 1. Sodium hydroxide is first added, and then the coagulant polyaluminum chloride and the coagulant polyacrylamide are added to the wastewater. The particulate and colloidal pollutants in the wastewater are first Under the action of polyaluminum chloride, a large number of small granular solid suspensions are formed, and then the solid suspensions formed in the wastewater are further polymerized under the action of polyacrylamide to form larger particles of flocs; among them, the inside and outside of the coagulation reaction tank The air compressor is connected, so that the input coagulant polyaluminum chloride and coagulant polyacrylamide can achieve rapid stirring in the wastewater;

[0020] (2) The effluent from the coagulation reaction tank 1 enters the sedimentation tank 2 for solid-liquid separation, and the effluent fro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap