A kind of graphene/polyaniline/cobalt composite absorbing material and preparation method thereof

A composite wave absorbing material and wave absorbing material technology are applied in the directions of radiation absorbing coatings, chemical instruments and methods, and other chemical processes, etc., which can solve the problems of reducing the density of absorbents, and achieve strong dielectric loss performance and simple preparation process. , the effect of absorbing frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

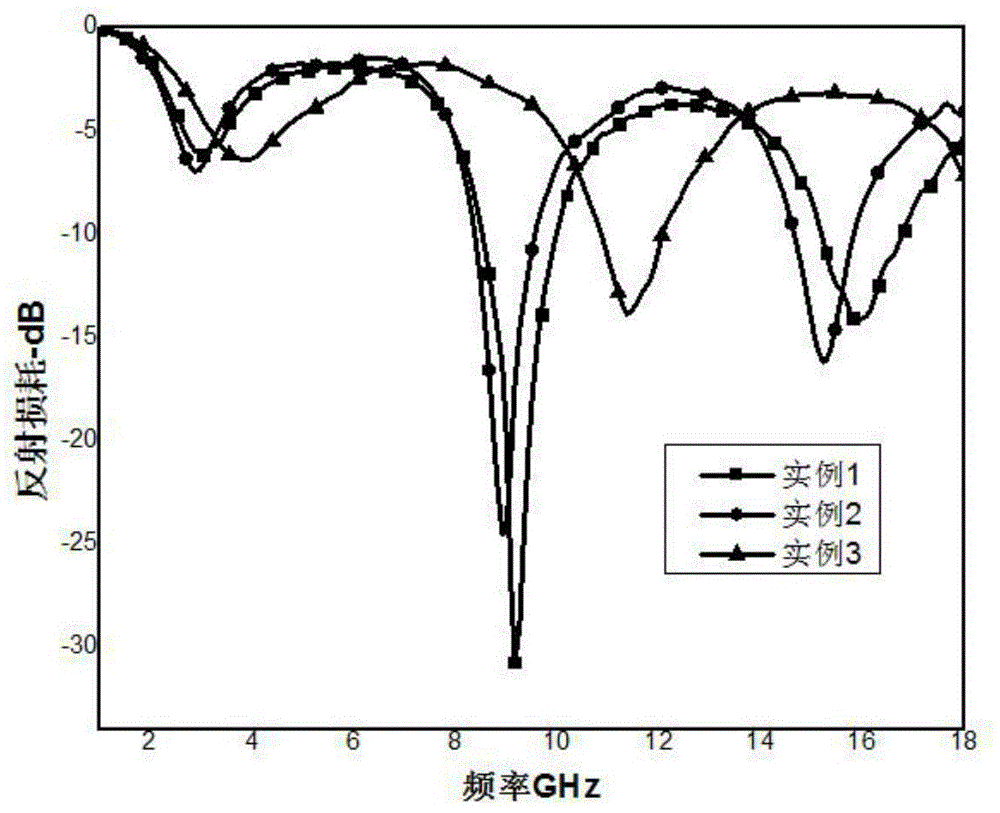

Embodiment 1

[0025] A preparation of absorbing material

[0026] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate to 40ml of concentrated sulfuric acid, cool in an ice bath to 4°C, and slowly add 5g of KMn0 4 , stirred and reacted for 90 minutes; then heated up to 30°C for 30 minutes; slowly added 50ml of deionized water, then stirred and reacted at 90°C for 20 minutes, cooled to room temperature, added 100ml of deionized water and 10ml of hydrogen peroxide, after centrifugal washing, vacuum drying to obtain oxidation graphite.

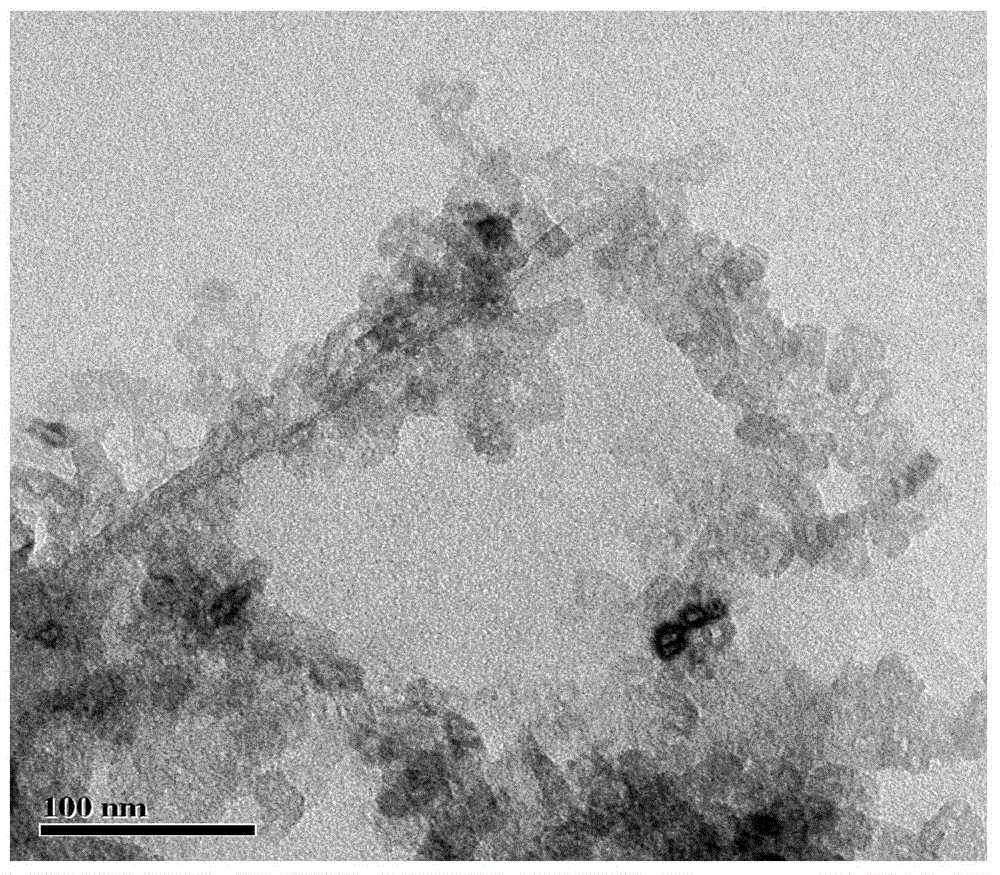

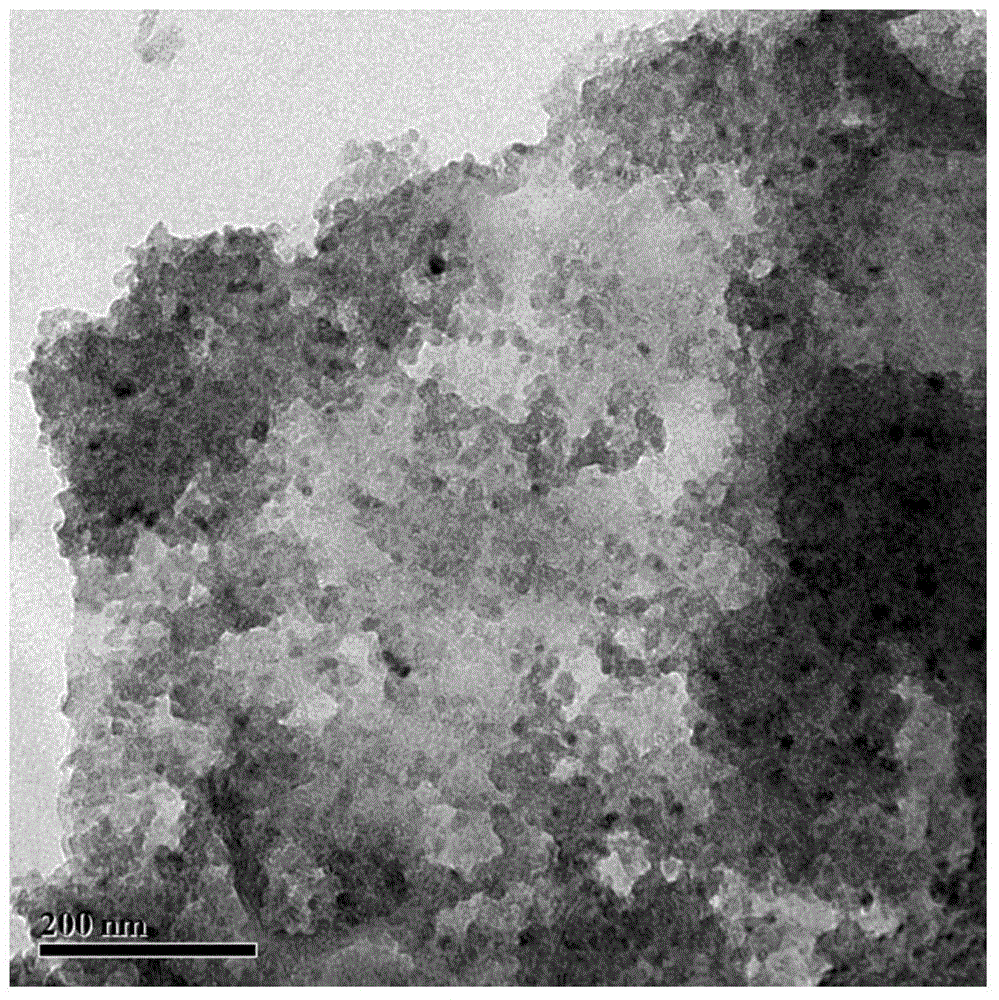

[0027] Weigh 0.11 g of graphite oxide, add 150 ml of deionized water and sonicate for 2 h to obtain a suspension of graphene oxide. Add 130ml of an acid solution containing 1.12g of aniline to the above graphene oxide suspension, stir at a constant speed for 20min, slowly add 20ml of an ammonium persulfate acid solution containing 1.82g of ammonium persulfate, react for 12h under ice bath conditions, and discard after standing still for 12 hours T...

Embodiment 2

[0032] A preparation of absorbing material

[0033] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate to 40ml of concentrated sulfuric acid, cool in an ice bath to 4°C, and slowly add 5g of KMn0 4 , stirred and reacted for 90 minutes; then heated up to 30°C for 30 minutes; slowly added 50ml of deionized water, then stirred and reacted at 90°C for 20 minutes, cooled to room temperature, added 100ml of deionized water and 10ml of hydrogen peroxide, after centrifugal washing, vacuum drying to obtain oxidation graphite.

[0034] Weigh 0.11 g of graphite oxide, add 150 ml of deionized water and sonicate for 2 h to obtain a suspension of graphene oxide. Add 130ml of acid solution containing 1.67g of aniline to the above graphene oxide suspension, stir at a constant speed for 20min, slowly add 20ml of ammonium persulfate acid solution containing 2.71g of ammonium persulfate, react for 12h under ice bath conditions, stand still for 12 hours and discard The supernatant ...

example 3

[0039] A preparation of absorbing material

[0040] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate to 40ml of concentrated sulfuric acid, cool in an ice bath to 4°C, and slowly add 5g of KMn0 4 , stirred and reacted for 90 minutes; then heated up to 30°C for 30 minutes; slowly added 50ml of deionized water, then stirred and reacted at 90°C for 20 minutes, cooled to room temperature, added 100ml of deionized water and 10ml of hydrogen peroxide, after centrifugal washing, vacuum drying to obtain oxidation graphite.

[0041] Weigh 0.11 g of graphite oxide, add 150 ml of deionized water and sonicate for 2 h to obtain a suspension of graphene oxide. Add 130ml of an acid solution containing 1.12g of aniline to the above graphene oxide suspension, stir at a constant speed for 20min, slowly add 20ml of an ammonium persulfate acid solution containing 1.82g of ammonium persulfate, react for 12h under ice bath conditions, and discard after standing still for 12 hours T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical bandwidth | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com