Preparation and application of high-graphitization fine ash coated square ZnSnO3 composite material

A composite material and high-graphite technology, applied in the direction of tin compounds, fibrous fillers, chemical instruments and methods, etc., can solve environmental pollution and other problems, and achieve the effect of improving MA performance, good impedance matching performance, and strong dielectric loss capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

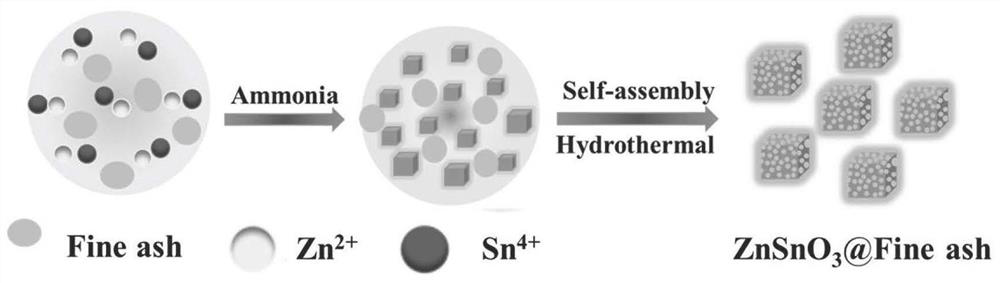

[0035] Highly graphitized fine ash coated square-like ZnSnO proposed by the present invention 3 The method steps of composite material preparation are as follows:

[0036] S1: Preparation of fine ash

[0037] The fine ash is prepared by using the gasification fine slag of pulverized coal as a raw material by a three-step acidification method; the specific steps are as follows:

[0038] S11: Using 50g of coal powder gasification fine slag as raw material, mix it with 500ml of hydrochloric acid solution (5mol / L) in a container, stir and filter;

[0039] S12: washing the solid obtained by filtering in S11 until neutral, and drying it;

[0040] S13: Mix the dried solid in S12 with 500ml of hydrofluoric acid solution (40%, wt%) in a container, stir, and filter, and wash the filtered solid with water until neutral, and dry it;

[0041] S14: Mix the dried solid in S13 with 500 mL hydrochloric acid solution (1.19 g / mL) in a container, stir, filter, wash the filtered solid with wate...

Embodiment 2

[0049] Highly graphitized fine ash coated square-like ZnSnO proposed by the present invention 3 The method steps of composite material preparation are as follows:

[0050] S1: Preparation of fine ash

[0051] The fine ash is prepared by using the gasification fine slag of pulverized coal as a raw material by a three-step acidification method; the specific steps are as follows:

[0052] S11: Using 50g of coal powder gasification fine slag as raw material, mix it with 500ml of hydrochloric acid solution (5mol / L) in a container, stir and filter;

[0053] S12: washing the solid obtained by filtering in S11 until neutral, and drying it;

[0054] S13: Mix the dried solid in S12 with 500ml of hydrofluoric acid solution (40%, wt%) in a container, stir, and filter, and wash the filtered solid with water until neutral, and dry it;

[0055] S14: Mix the dried solid in S13 with 500 mL hydrochloric acid solution (1.19 g / mL) in a container, stir, filter, wash the filtered solid with water,...

Embodiment 3

[0063] Highly graphitized fine ash coated square-like ZnSnO proposed by the present invention 3 The method steps of composite material preparation are as follows:

[0064] S1: Preparation of fine ash

[0065] The fine ash is prepared by using the gasification fine slag of pulverized coal as a raw material by a three-step acidification method; the specific steps are as follows:

[0066] S11: Using 50g of coal powder gasification fine slag as raw material, mix it with 500ml of hydrochloric acid solution (5mol / L) in a container, stir and filter;

[0067] S12: washing the solid obtained by filtering in S11 until neutral, and drying it;

[0068] S13: Mix the dried solid in S12 with 500ml of hydrofluoric acid solution (40%, wt%) in a container, stir, and filter, and wash the filtered solid with water until neutral, and dry it;

[0069] S14: Mix the dried solid in S13 with 500 mL hydrochloric acid solution (1.19 g / mL) in a container, stir, filter, wash the filtered solid with wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com