Polyaniline/graphene oxide/ferric oxide absorbing material and preparation method

A technology of triiron tetroxide and graphene, which is applied in the field of preparation of new polyaniline/graphene oxide/iron tetroxide composite materials, can solve the problems of reducing the density of absorbents, less graphene oxide, etc., to improve the magnetic loss , the effect of large surface energy and large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

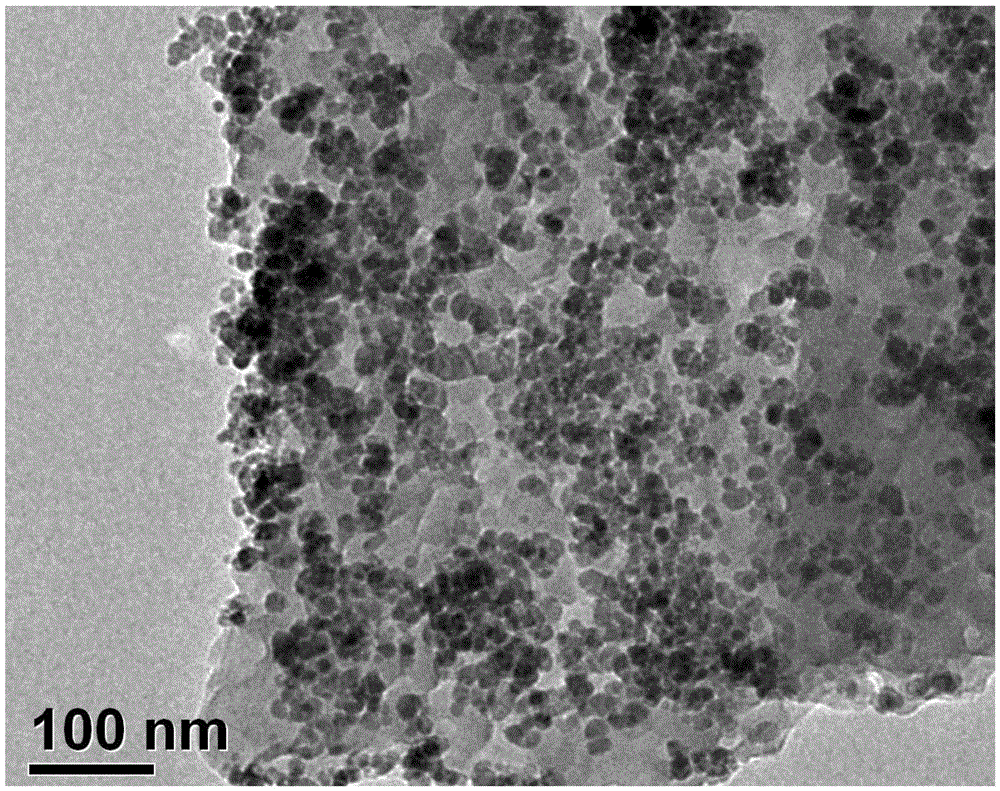

[0021] A preparation of absorbing material

[0022] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate into 50mL of concentrated sulfuric acid, cool in an ice bath to 4°C, slowly add 5g of potassium permanganate, stir for 90min; then raise the temperature to 35°C and stir for 4h; slowly add 100mL Deionized water, stirred at 90°C for 2h, cooled to room temperature, added 10mL of hydrogen peroxide, washed by centrifugation and vacuum dried to obtain graphite oxide.

[0023] (2) 1.99gFeCl 2 4H 2 O and 4.06 g FeCl 3 ·H 2 O was added to 100mL deionized water, stirred to dissolve, 20mL ammonia water (28wt%) was quickly added to the above solution, stirred vigorously, and the water was kept at a constant temperature of 75°C. When the mixed solution changed from orange red to black, continue to stir for 15min. Centrifugal washing and vacuum drying to obtain ferric oxide.

[0024] (3) Weigh 1g of aniline and 0.5g of ferric oxide into 100mL containing 0.25MFeCl 3 and...

Embodiment 2

[0028] A preparation of absorbing material

[0029] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate into 50mL of concentrated sulfuric acid, cool in an ice bath to 4°C, slowly add 5g of potassium permanganate, stir for 90min; then raise the temperature to 35°C and stir for 4h; slowly add 100mL Deionized water, stirred at 90°C for 2h, cooled to room temperature, added 10mL of hydrogen peroxide, washed by centrifugation and vacuum dried to obtain graphite oxide.

[0030] (2) 1.99gFeCl 2 4H 2 O and 4.06 g FeCl 3 ·H 2 O was added to 100mL deionized water, stirred to dissolve, 20mL ammonia water (28wt%) was quickly added to the above solution, stirred vigorously, and the water was kept at a constant temperature of 75°C. When the mixed solution changed from orange red to black, continue to stir for 15min. Centrifugal washing and vacuum drying to obtain ferric oxide.

[0031] (3) Weigh 1g of aniline and 1g of ferric oxide into 100mL containing 0.25MFeCl 3 and 0....

Embodiment 3

[0035] A preparation of absorbing material

[0036] (1) Add 1g of natural flake graphite and 0.5g of sodium nitrate into 50mL of concentrated sulfuric acid, cool in an ice bath to 4°C, slowly add 5g of potassium permanganate, stir for 90min; then raise the temperature to 35°C and stir for 4h; slowly add 100mL Deionized water, stirred at 90°C for 2h, cooled to room temperature, added 10mL of hydrogen peroxide, washed by centrifugation and vacuum dried to obtain graphite oxide.

[0037] (2) 1.99gFeCl 2 4H 2 O and 4.06 g FeCl 3 ·H 2 O was added to 100mL deionized water, stirred to dissolve, 20mL ammonia water (28wt%) was quickly added to the above solution, stirred vigorously, and the water was kept at a constant temperature of 75°C. When the mixed solution changed from orange red to black, continue to stir for 15min. Centrifugal washing and vacuum drying to obtain ferric oxide.

[0038] (3) Weigh 1g of aniline and 1.5g of ferric oxide into 100mL containing 0.25MFeCl 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical bandwidth | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com