ZnO-C/Al2SiO5 low-density high-loss complex-phase wave-absorbing ceramic and preparation method thereof

A multi-phase ceramic and high-loss technology, applied in the field of wave-absorbing materials, can solve the problems of low dielectric loss in the imaginary part of the dielectric constant, the need to improve the conductance loss capability, and the low conductivity of ZnO, so as to avoid electromagnetic reflection and shorten the cycle , the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

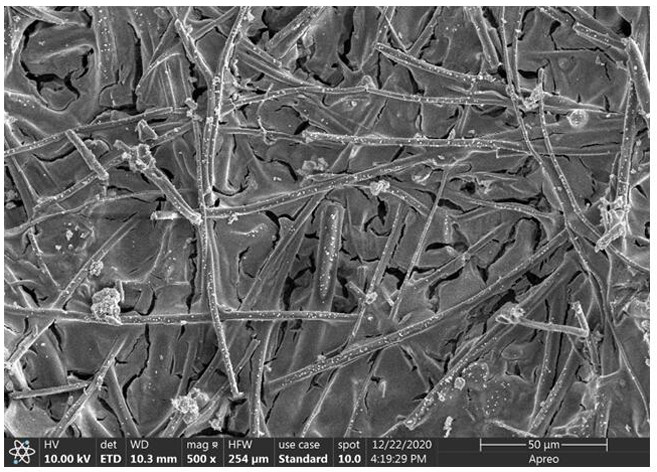

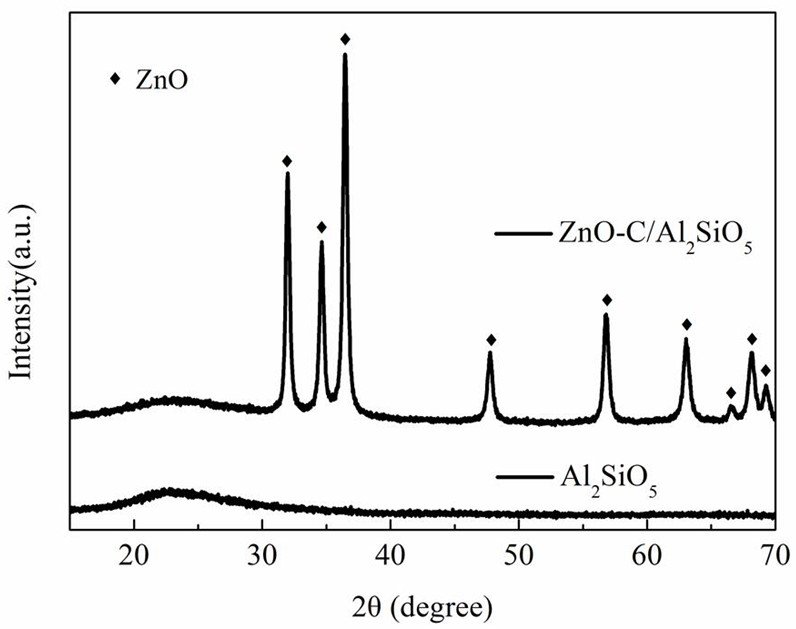

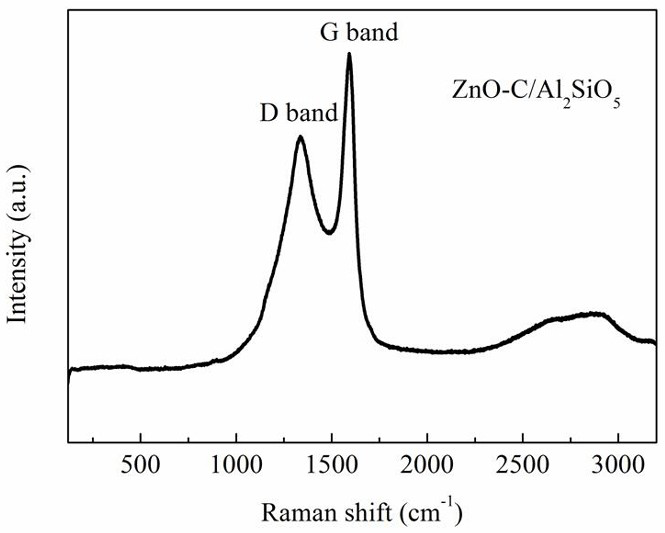

[0033] The invention discloses a porous ZnO-C / Al 2 SiO 5 Low-density high-loss complex-phase wave-absorbing ceramics; the porous ZnO-C / Al 2 SiO 5 Composite ceramics with porous Al 2 SiO 5 The ceramic fiberboard is a wave-transparent matrix, and in Al 2 SiO 5 The internal pores of the ceramic fiber board are uniformly filled with C and ZnO two-phase particles; the density of the composite ceramic is ≤0.6g / cm 3 , has strong loss performance and excellent microwave absorption performance, and the preparation method of the material specifically includes the following steps:

[0034] 1) Mix glucose and zinc acetate evenly at a molar ratio, then add deionized water to stir and dissolve, and stir the mixed solution at 60°C for 1 h to obtain a glucose-zinc acetate composite solution. The molar ratio of glucose and zinc acetate is Between 1:1 and 1:4, the concentration of glucose in the solution is 0.05g / mL, and the concentration of zinc acetate in the solution is 0.05~0.2 g / mL;...

Embodiment 1

[0039] 1) Mix glucose and zinc acetate evenly at a molar ratio of 1:1, then add deionized water and stir to dissolve. The concentration of glucose in the solution is 0.05 g / mL, and the concentration of zinc acetate in the solution is 0.05 g / mL. Stir magnetically for 0.5 h at 60°C to obtain a mixed solution of glucose-zinc acetate;

[0040] 2) Cut the porous Al into the desired size 2 SiO 5 Immerse the ceramic fiberboard into the solution in step 1), vacuum impregnate for 0.5h, and the vacuum degree is less than 50Pa, and prepare a preform. The prepared preform is dried at 100°C for 0.5h, and then heat-treated at 300°C for 0.5h. The heating rate is 5°C / min to obtain porous ZnO-C / Al impregnated once 2 SiO 5 For the composite ceramic body, the drying process does not require a protective atmosphere, it is carried out in an air environment, and the heat treatment is carried out in an Ar atmosphere protection;

[0041] 3) Immerse the multiphase ceramic body in step 2) into the ...

Embodiment 2

[0048] 1) Mix glucose and zinc acetate evenly in a molar ratio of 1:2, then add deionized water and stir to dissolve. The concentration of glucose in the solution is 0.05g / mL, and the concentration of zinc acetate in the solution is 0.1 g / mL. Stir magnetically for 0.5 h at 60°C to obtain a mixed solution of glucose-zinc acetate;

[0049] 2) Cut the porous Al into the desired size 2 SiO 5 Immerse the ceramic fiberboard into the solution in step 1), vacuum impregnate for 0.5h, and the vacuum degree is less than 50Pa, and prepare a preform. The prepared preform is dried at 100°C for 0.5h, and then heat-treated at 300°C for 0.5h. The heating rate is 5°C / min to obtain porous ZnO-C / Al impregnated once 2 SiO 5 For the composite ceramic body, the drying process does not require a protective atmosphere, it is carried out in an air environment, and the heat treatment is carried out in an Ar atmosphere protection;

[0050] 3) Immerse the multiphase ceramic body in step 2) into the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com