Fully automatic railway bearing assembling and inspecting production line

A railway bearing and production line technology, which is applied to bearing components, shafts and bearings, measuring devices, etc., can solve the problems of inability to cover the railway bearing assembly production process and has a large impact, and achieve increased mutual consistency, high production efficiency, and application Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings.

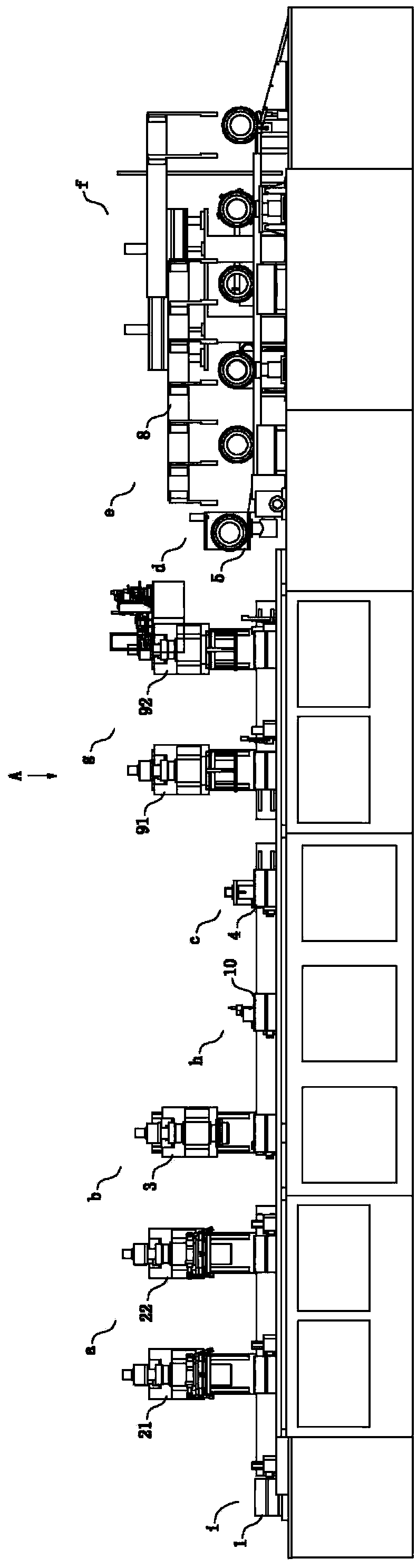

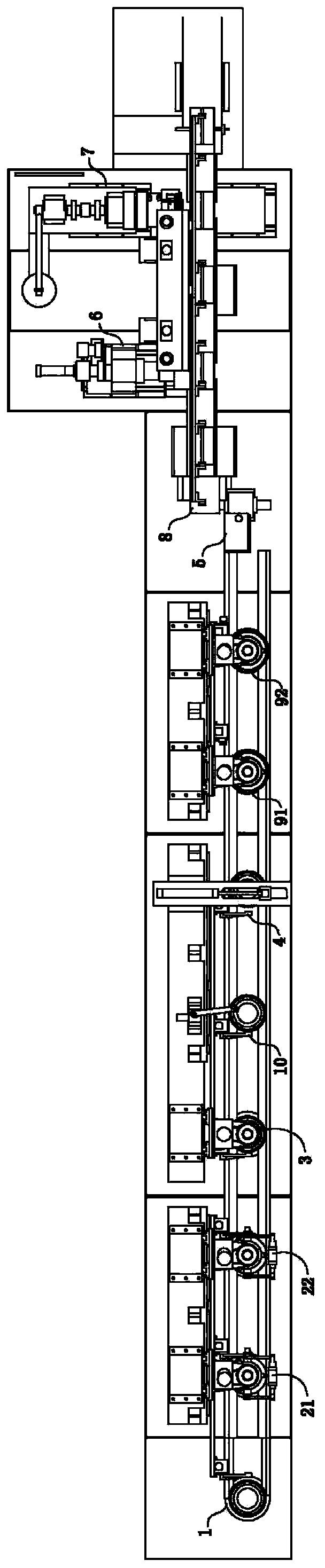

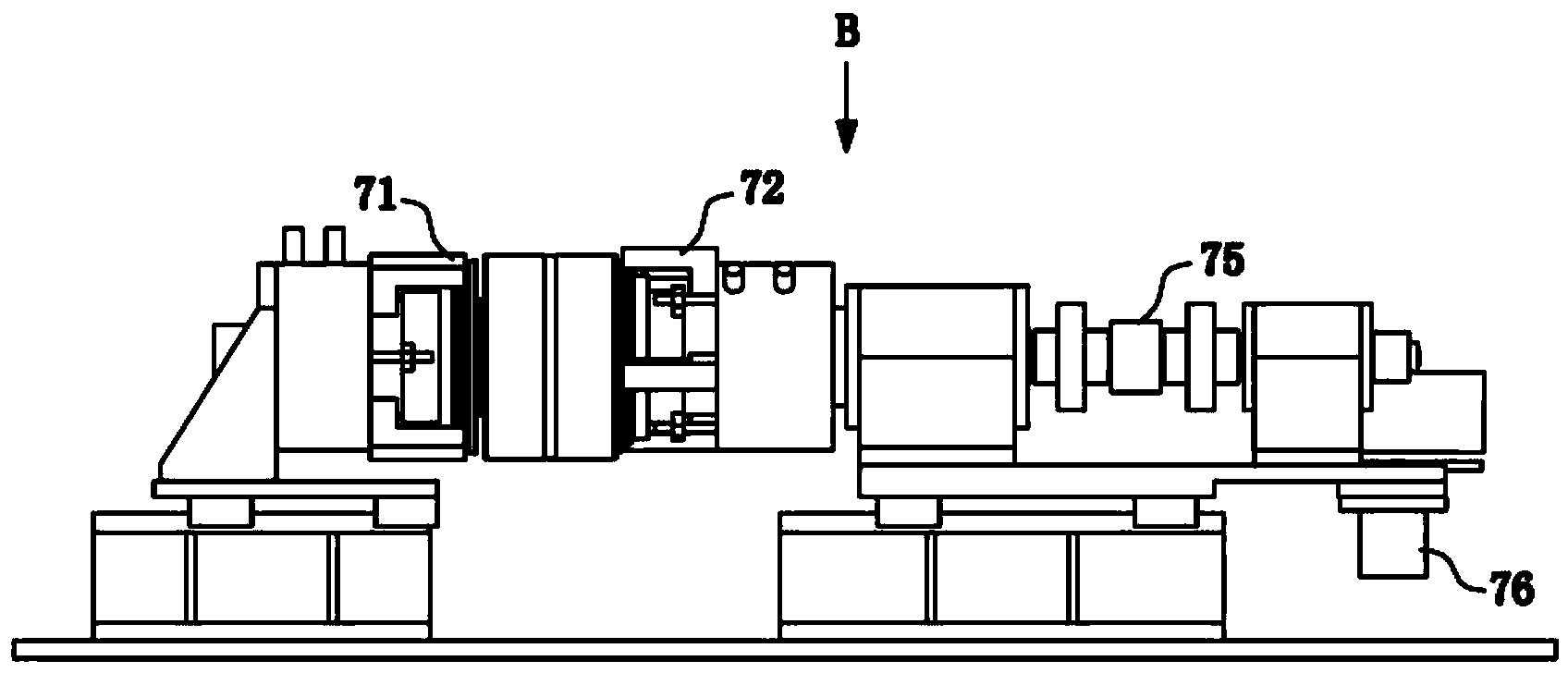

[0034] refer to figure 1 and figure 2 As shown, one embodiment of the present invention is a fully automatic railway bearing assembly and inspection production line, which is provided with a first inspection station i, a first cleaning and drying station a, a clearance inspection station b, Pushing out station c, flipping station d, grease injection station e, and pressure casing torque measuring station f, the aforementioned seven stations are respectively equipped with various automatic equipment for railway bearing assembly, as follows:

[0035] Install the upper and lower inner component detection device 1 on the first detection station i, its function in the production line is to detect whether the assembly of the upper and lower inner ring components of the railway bearing passing through the station is completed through the probe;

[0036] Install the front cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com