Valve ball made of plastic of ball valve

A valve ball, ball valve technology, applied in valve details, valve device, thin material processing and other directions, can solve problems such as damage to the bushing, achieve the effect of light structure and improved shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

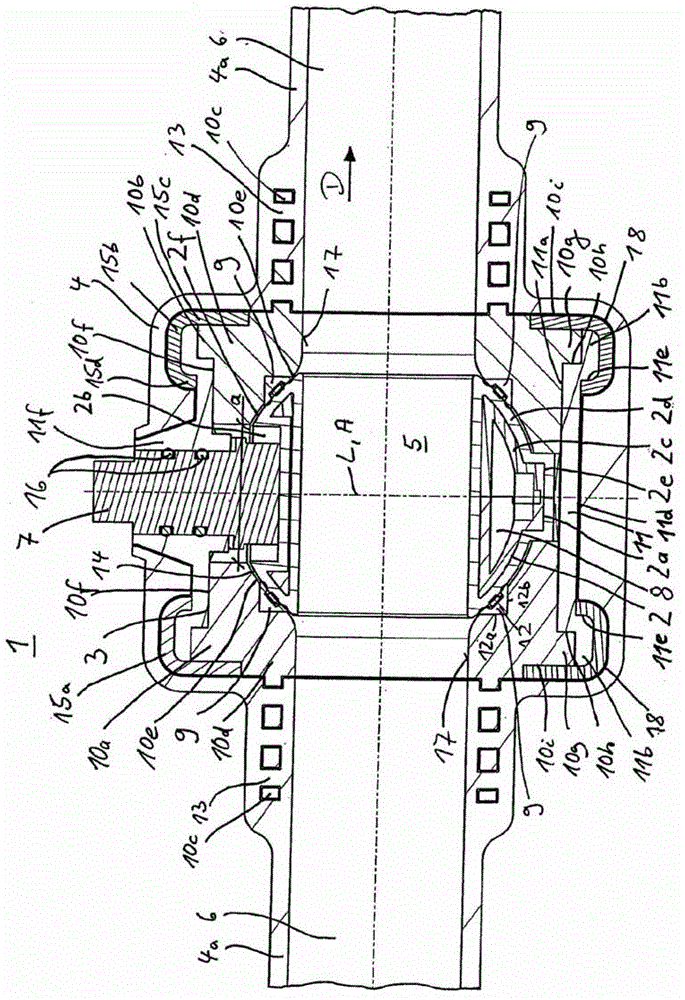

[0020] figure 1 A longitudinal section through a ball valve 1 according to the invention is shown. Seen from the inside to the outside, the ball valve 1 basically consists of a valve ball 2 , a support structure 3 and a housing 4 .

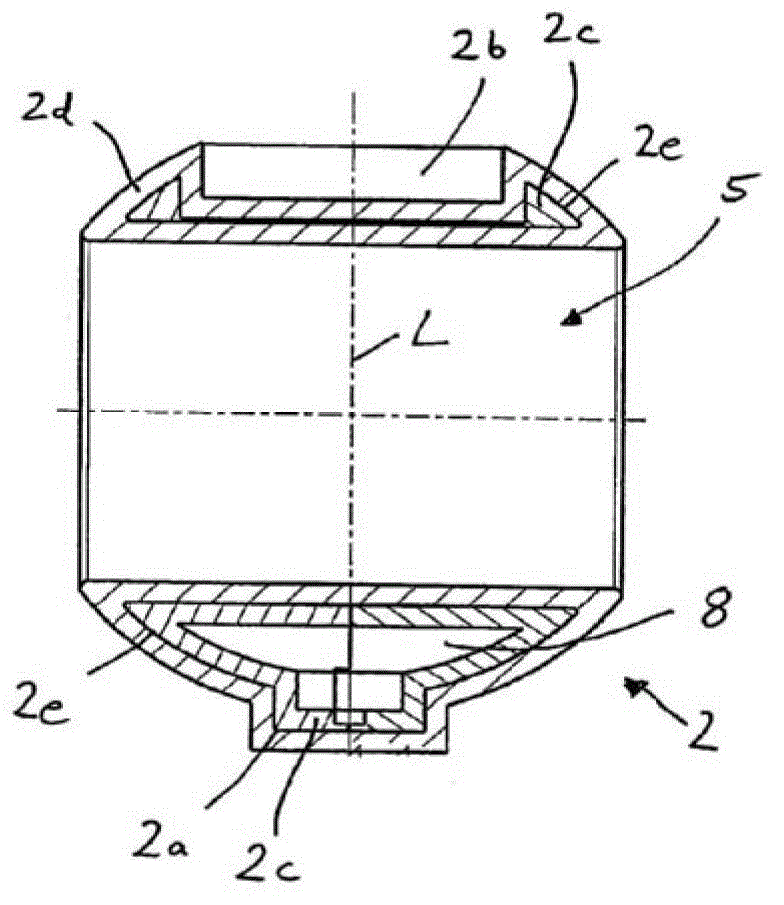

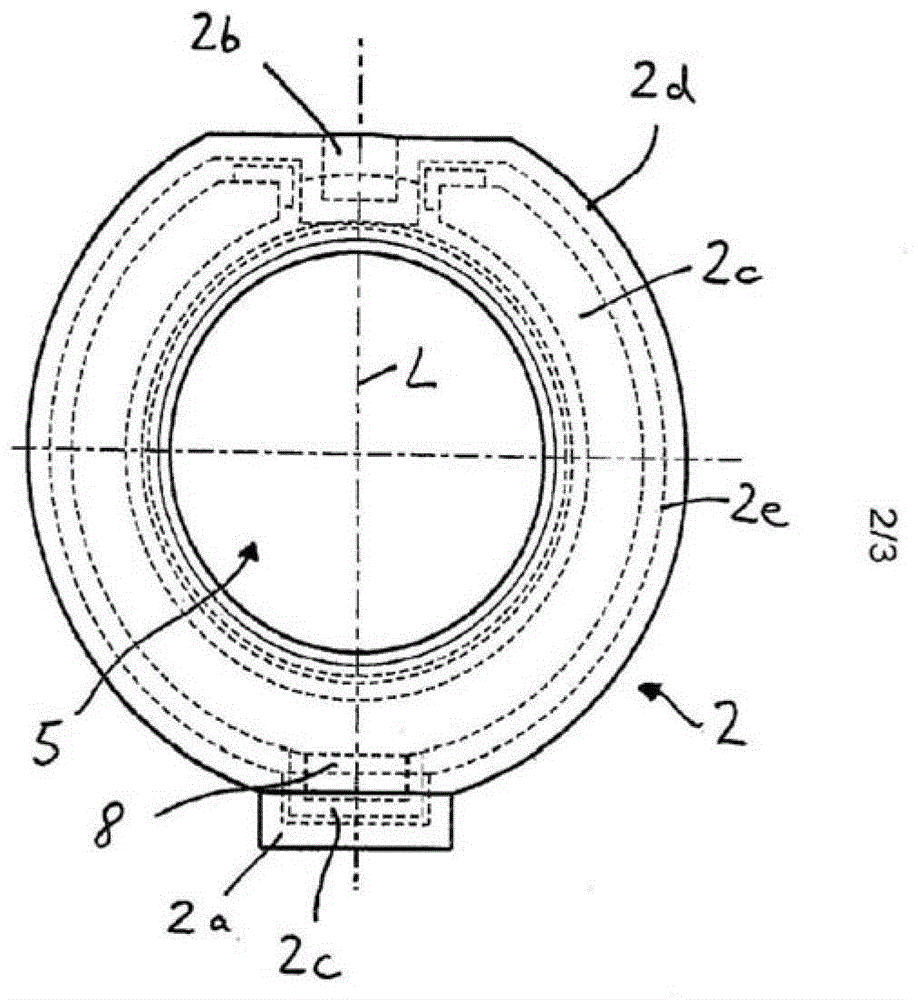

[0021] The valve ball 2 used as a shut-off in the ball valve 1 usually has a central cylindrical through-hole 5 . figure 1 shows that the valve ball 2 is in the open valve position. In this position, the through-opening 5 connects two connecting pipes 4 a arranged opposite to each other, which are integral parts of the housing 4 , so that fluid can flow through the ball valve 1 . In order to be able to move the valve ball 2 from its open valve position to its closed position from the open valve position to the shut-off valve position, it is rotatably mounted in the support structure 3 about an axis A which is vertical in this case. For this purpose, an annular journal 2 a is provided in the region of the lower end of the valve ball 2 , the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com