Device for testing performance of magnetic shape memory alloy

A memory alloy and testing device technology, applied in the field of magnetron memory alloys, achieves the effects of compact structure, high measurement accuracy, and prevention of external magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

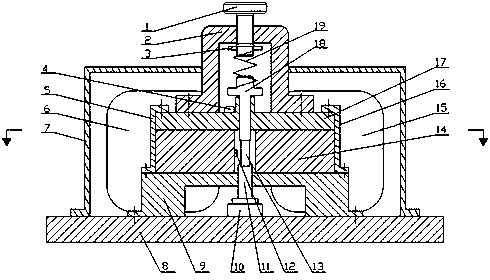

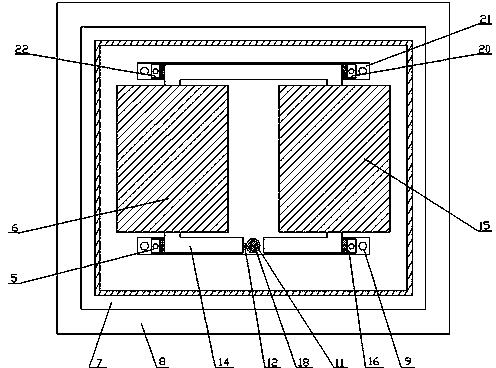

[0019] A device for testing the properties of a magnetically controlled shape memory alloy. The device such as figure 1 and figure 2 As shown, the front support frame 9 and the rear support frame 21 are fixed symmetrically on the front and back of the base 8, the front support frame 9 and the rear support frame 21 are provided with an iron core 14, and the upper plane of the iron core 14 front is provided with a connecting plate 17 . The upper ends of the front left splint 5 and the front right splint 16 are correspondingly pressed on the left end and the right end of the connecting plate 17, and the lower ends of the front left splint 5 and the front right splint 16 are correspondingly fixed on the left end and the right end of the front support frame 9; the rear left splint 22 The upper end of the rear right splint 20 is correspondingly pressed on the upper plane of the rear left corner and the rear right corner of the iron core 14, and the lower ends of the rear left spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com