A vacuum gauge calibration method and device for pressure measurement

A calibration method and vacuum gauge technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of limited range and effect, relying on manual processing, time-consuming, etc., achieve intuitive and optional methods, reduce calibration workload, and operate concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0047]The calibration process uses a standard vacuum device that meets the specifications to provide the required calibration pressure Pa data within the regulatory working pressure range, and the output electrical signal of the corresponding regulatory measurement circuit is the measured data. Calibration uses the dynamic direct comparison method, the basic principle of which is to connect the vacuum gauge to be tested and the standard vacuum gauge to the same calibration chamber, the pressure required by the chamber is obtained through dynamic balance adjustment, and the fine-tuning needle valve is used to adjust the pressure of the calibration chamber. Use a standard vacuum gauge as a monitor.

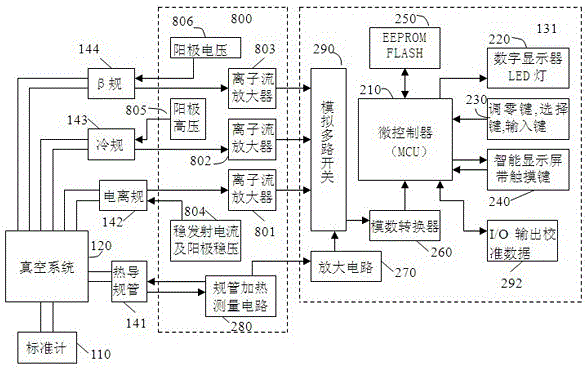

[0048] Such as figure 1 The shown self-calibrating vacuum gauge system device consists of regulation, regulation work and detection circuit, data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com