Method for quickly detecting water content of emulsified asphalt cold-recycling mixture

A technology for cold recycled mixture and asphalt mixture, which is applied in the direction of using material absorption and weighing, etc., can solve the problems of inability to guide the production of mixture in real time, and the slow detection rate of water content of emulsified asphalt cold recycled mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

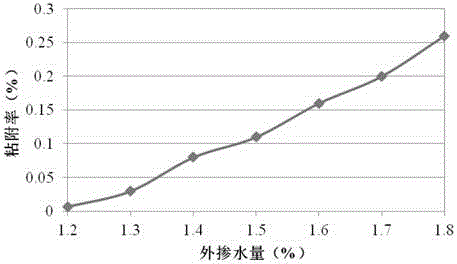

[0037] Control the water content in the production process of the mixture for the Huaxi Road emulsified asphalt cold recycling project. According to the design results of the mix ratio, the external water content: W=1.5%.

[0038] The results of the indoor calibration test are shown in Table 1.

[0039] Table 1 Indoor calibration test results

[0040]

[0041] standard curve as figure 1 shown.

[0042] The results of field testing are shown in Table 2:

[0043] Table 2 On-site inspection test results

[0044]

[0045]

[0046] The production of emulsified asphalt cold recycled mixture is controlled in real time by the rapid detection method of emulsified asphalt cold recycled mixture, which ensures the performance of emulsified asphalt cold recycled mixture. The performance sampling results of emulsified asphalt cold recycled mixture produced on site are as follows:

[0047] Table 3 Field sampling results of performance of emulsified asphalt cold recycled mixture ...

Embodiment 2

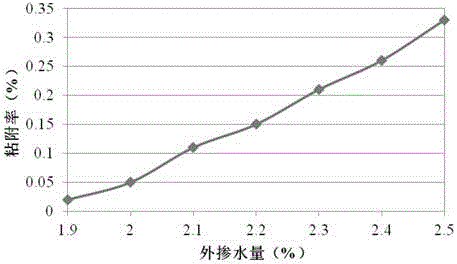

[0050] The water content in the production process of the mixed material for the east extension of Baima Road emulsified asphalt cold recycling project is controlled. According to the design results of the mix ratio, the external water content: W=2.2%.

[0051] The results of the indoor calibration test are shown in Table 4.

[0052] Table 4 Indoor calibration test results

[0053]

[0054] standard curve as figure 2 shown.

[0055] The results of on-site inspection and the adjustment suggestions for external water mixing are shown in Table 5:

[0056] Table 5 On-site inspection test results

[0057]

[0058]

[0059] The production of emulsified asphalt cold recycled mixture is controlled in real time by the rapid detection method of emulsified asphalt cold recycled mixture, which ensures the performance of emulsified asphalt cold recycled mixture. The performance sampling results of emulsified asphalt cold recycled mixture produced on site are as follows:

[00...

Embodiment 3

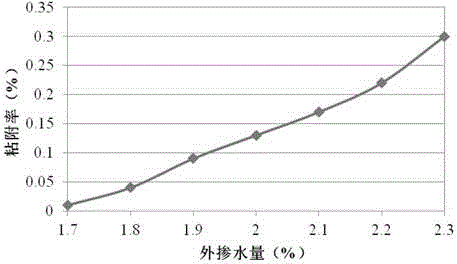

[0063] Daxing Tuanzhong Road Emulsified Asphalt Cold Recycling Project will control the water content in the production process of the mixture. According to the design results of the mix ratio, the external water content: W=2.0%.

[0064] The results of the indoor calibration test are shown in Table 7.

[0065] Table 7 Indoor calibration test results

[0066]

[0067] standard curve as image 3 shown.

[0068] The results of field testing are shown in Table 8:

[0069] Table 8 On-site inspection test results

[0070]

[0071] The production of emulsified asphalt cold recycled mixture is controlled in real time by the rapid detection method of emulsified asphalt cold recycled mixture, which ensures the performance of emulsified asphalt cold recycled mixture. The performance sampling results of emulsified asphalt cold recycled mixture produced on site are as follows:

[0072] Table 6 Field sampling results of performance of emulsified asphalt cold recycled mixture

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com