Ultrasonic detection device for circumferential weld of bottom head of reactor pressure vessel

A technology for nuclear reactors and pressure vessels, applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as welds that are prone to corrosion, serious safety accidents, and slag inclusions, and reduce radiation exposure , Improve the effect of accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A nuclear reactor pressure vessel bottom head girth weld ultrasonic inspection device according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

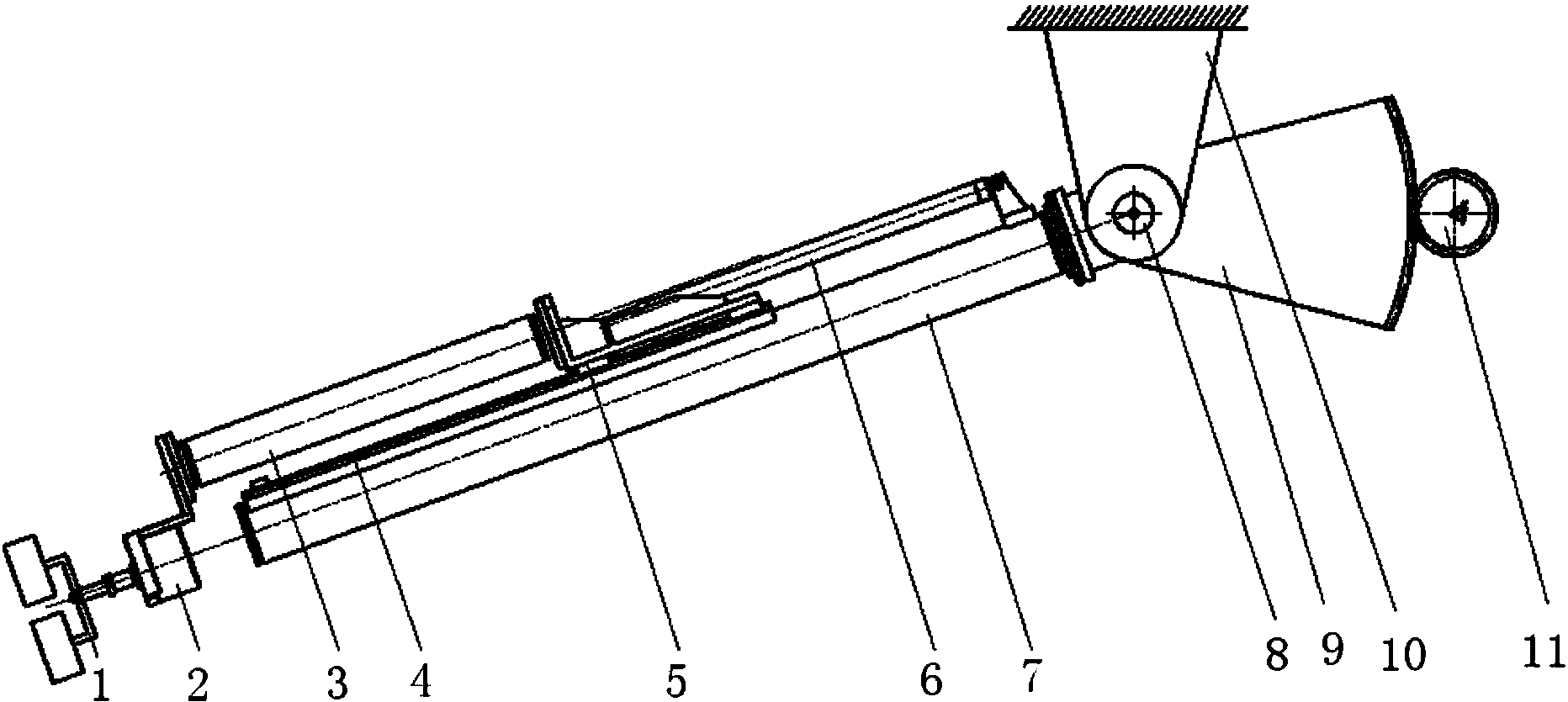

[0014] Such as figure 1 As shown, a nuclear power plant nuclear reactor pressure vessel bottom head girth weld ultrasonic inspection device according to the present invention includes a frame 10 connected by a rotating shaft 8, a swing gear 9 and a swing rod 7; the swing gear 9 and the swing The rod 7 is screwed, and the driving element 11 drives the swing gear 9 to swing, so that the swing rod 7 swings around the rotating shaft 8 .

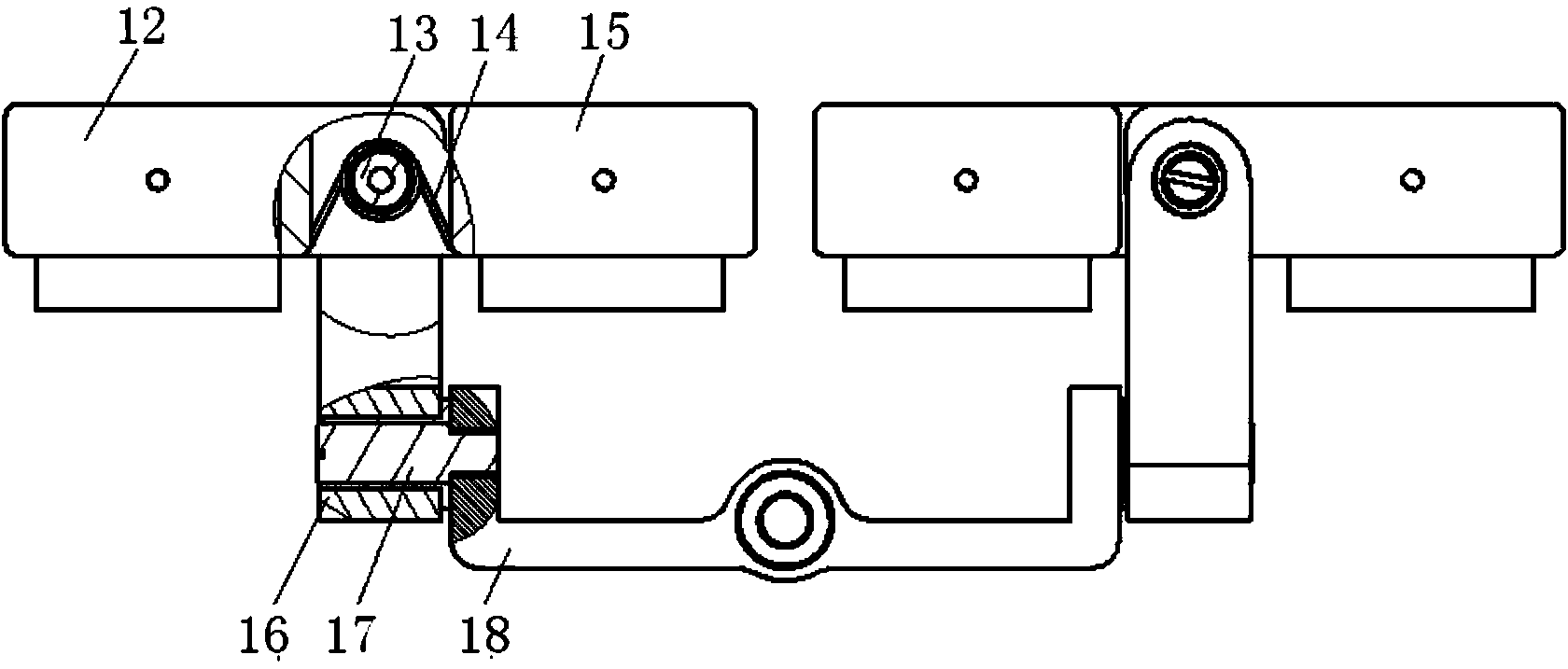

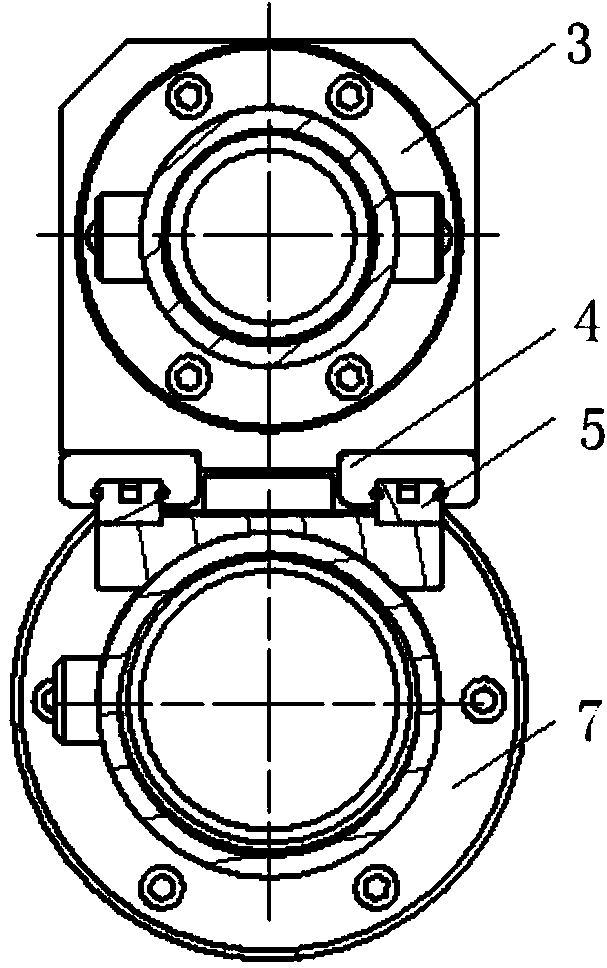

[0015] Such as figure 1 and image 3 As shown, the linear guide rail 4 and the telescopic cylinder 6 are fixed above the swing rod 7, the slider 5 is arranged on the linear guide rail 4, the extension rod 3 is fixed on the slider 5, and one end of the extension rod 3 is connected with the telescopic cylinder 6 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com