Method of testing alternating current voltage resistance performance of multi-core cable

A multi-core cable, withstanding voltage technology, applied in the direction of testing dielectric strength, etc., can solve the problems of cumbersome, time-consuming and energy-consuming, cable damage, etc., to improve testing efficiency, reduce testing times, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

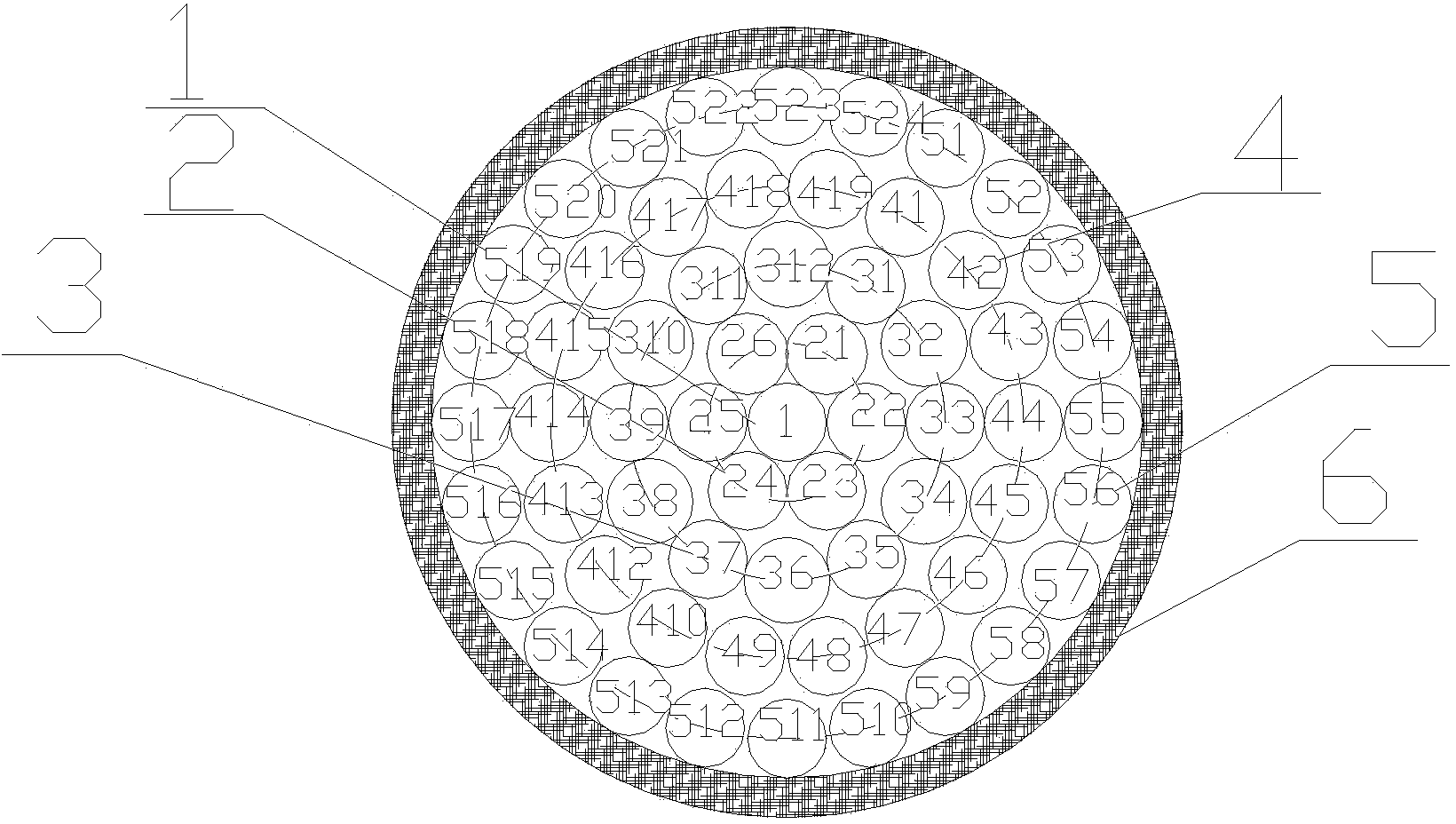

[0020] See attached figure 1 , a cable with cores arranged in (1+6+12+18+24), the cores are divided into 1, 2, 3, 4, 5 layers, and each layer is divided into 11, 12, 13, 14 , 15..., 21, 22, 23, 24, 25..., 31, 32, 33, 34, 35..., 41, 42, 43, 44, 45..., 51, 52, 53, 54, 55... and other wire cores , put all the wire cores together, conduct an AC withstand voltage test with the shielding layer, and take all the wire cores in the 1st, 3rd, and 5th layers of the withstand voltage test as a group, and all the wire cores in the 2nd and 4th layers as a group , the AC withstand voltage test is carried out between the two groups, so that each core and the upper and lower adjacent cores are tested for electrical resistance; the adjacent cores of the same layer are tested for electrical resistance, and the second layer 21, 23 , 25... wire cores constitute the first group of the second layer, 22, 24... wire cores constitute the second group of the second layer, and the third layer 31, 33, 35...

Embodiment 2

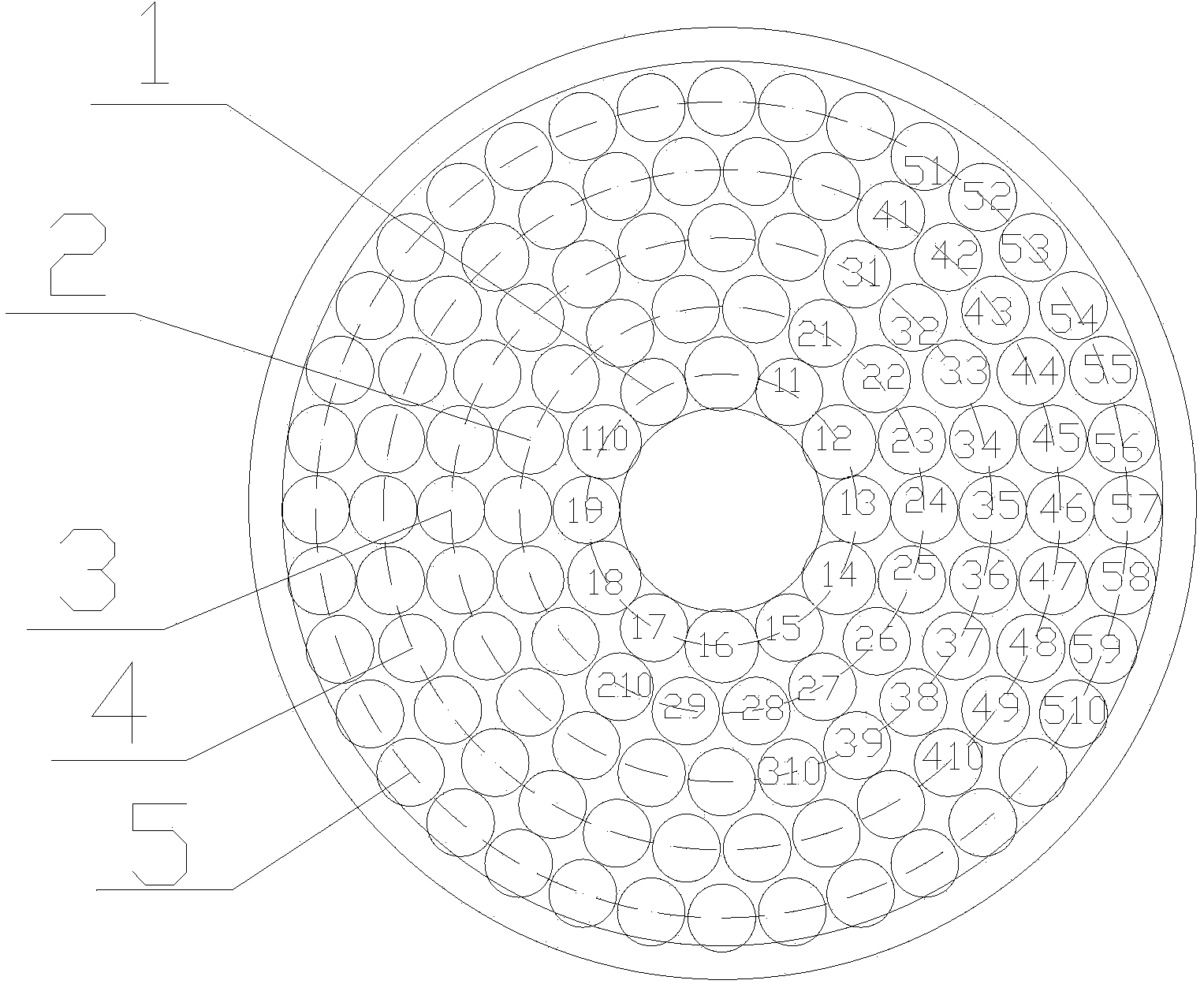

[0022] See attached figure 2 , a multi-core cable without shielding layer, the cores are arranged in (6+12+18+24+30+36), the cores are labeled in layers, and the cores are divided into 1, 2, 3, 4, 5 layers, divide each layer into 11, 12, 13, 14, 15..., 21, 22, 23, 24, 25..., 31, 32, 33, 34, 35..., 41, 42, 43, 44, 45 ..., 51, 52, 53, 54, 55... and other wire cores, since the wire cores have no shielding layer, the AC withstand voltage test of the wire cores can be carried out directly, and the odd-numbered layer cores are placed in one group, and the even-numbered The other group, carry out the AC withstand voltage test between the two groups; put the odd-numbered wire cores of each layer in one group, and the even-numbered wire cores in each layer in the other group, and conduct the AC withstand voltage test between the two groups Test to detect the insulation performance of multi-core cables and detect whether the cable insulation is defective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com